Determination method for trace thallium in high-salt waste water

A technology of high-salt wastewater and determination method, which is applied in the field of heavy metal detection, can solve the problems of expensive equipment investment and operation cost, low detection limit, spray rate reduction, etc., and achieve the effect of low detection and operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

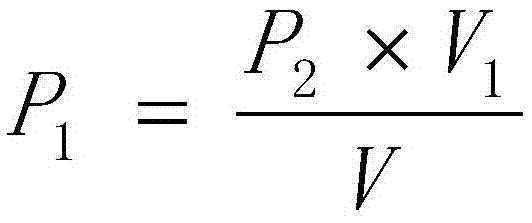

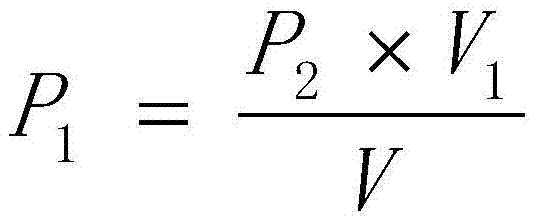

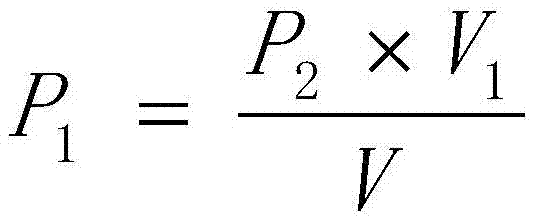

Image

Examples

Embodiment 1

[0045] A method for detecting trace thallium in high-salt wastewater, comprising the following steps:

[0046] (1) Wastewater collection, transfer and storage: Take 200mL of wastewater from a factory in the hydrometallurgical industry (sodium content is 40g / L, thallium content is 8.10μg / L), seal it, and analyze it; if it cannot be analyzed in time, add nitric acid Acidify, adjust the pH to 1, and then store it below 4°C for no more than 5 days; when measuring, adjust the pH of the high-salt wastewater sample to 3.82 with ammonia water, and then extract; the mass fraction of the nitric acid is 65% ;

[0047] (2) Sample pretreatment:

[0048] ① Transfer the water sample from the sampling bottle to a 500mL beaker, and rinse the polyethylene bottle twice with 10mL of pure water each time, pour the rinsed water into the transferred water sample in turn, and mix well; The pH of the water sample adjusted by ammonia water is 3.82;

[0049]②Use 100mL of the saponified organic phase ...

Embodiment 2

[0062] A method for detecting trace thallium in high-salt wastewater, comprising the following steps:

[0063] (1) Wastewater collection, transfer and storage: Take 400mL of wastewater samples (sodium content is 5g / L, thallium content is 0.52μg / L) outside the sewage treatment station of a factory in the hydrometallurgical industry, seal it, and analyze it; The effluent waste water is the waste water after removing heavy metals from the raffinate waste water and adjusting the value through sand filtration; if it cannot be analyzed in time, add nitric acid to acidify, adjust the pH to 2, and then store it below 4°C for no more than 5 days; when measuring , adjusting the pH of the high-salt wastewater sample to 3.95 with ammonia water, and then extracting; the mass fraction of the nitric acid is 98%;

[0064] (2) Sample pretreatment:

[0065] ① Transfer the water sample from the sampling bottle to a 1000mL beaker, and rinse the polyethylene bottle 3 times with 10mL of pure water...

Embodiment 3

[0079] A method for detecting trace thallium in high-salt wastewater, comprising the following steps:

[0080] (1) Wastewater collection, transfer and storage: Take a 300mL sample of wastewater from a factory in the hydrometallurgical industry (with a sodium content of 0.5g / L and a thallium content of 0.1μg / L), seal it, and analyze it; if it cannot be analyzed in time, add Acidify with nitric acid, adjust the pH to 1.5, and then store at below 4°C for no more than 5 days; when measuring, adjust the pH of the high-salt wastewater sample to 3.5 with ammonia water, and then extract; the mass fraction of the nitric acid is 80 %;

[0081] (2) Sample pretreatment part:

[0082] ① Transfer the water sample from the sampling bottle to a 500mL beaker, and rinse the polyethylene bottle twice with 10mL of pure water each time, pour the rinsed water into the transferred water sample in turn, and mix well; The pH of the water sample adjusted by ammonia water is 3.5;

[0083] ②Use 100mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com