Neural restoration sleeve tube and preparation method and application thereof

A nerve repair and cannula technology, applied in the field of nerve cannula, can solve the problems of nerve compression, difficulty in use, and difficulty in batch production of natural protein, and achieve good strength and stability, good biocompatibility, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

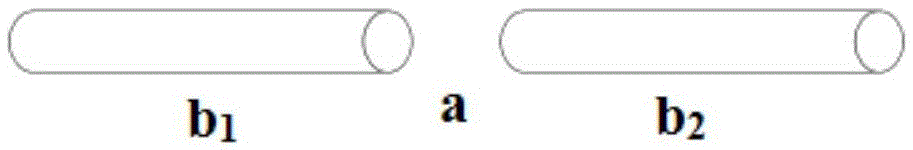

Image

Examples

Embodiment 1

[0042] In this embodiment, the nerve repair sleeve is prepared by the following method, which specifically includes the following steps:

[0043] (1) Dissolve polycaprolactone in a mixture of chloroform and N,N-dimethylformamide at a volume ratio of 1:1 to prepare a solution with a mass volume concentration of 30%, and then stir at 50°C 24h obtains polymer solution;

[0044] (2) The polymer solution is injected into the electrospinning equipment through a syringe (with a No. 5 stainless steel needle, 1-5mm in diameter) for spinning. The parameters during spinning are set as follows: the spinneret voltage is 10kV, and the solution flow rate is 5mL / h; the formed fiber is ejected from the spinneret of the electrospinning equipment, the receiving distance between the receiving device and the spinneret is 5cm, the receiving device is equipped with double electrodes as the receiving electrodes, and the axes of the double electrodes are parallel on the same horizontal line permutat...

Embodiment 2

[0046] In this embodiment, the nerve repair sleeve is prepared by the following method, which specifically includes the following steps:

[0047] (1) Glycolide-lactide copolymer (glycolide content greater than 80%) is dissolved in a mixture of chloroform and N,N-dimethylformamide with a volume ratio of 2:1 to prepare A solution with a mass volume concentration of 10%, and then stirred at 60° C. for 20 hours to obtain a polymer solution;

[0048] (2) The polymer solution is injected into the electrospinning equipment through a syringe (with a No. 5 stainless steel needle, 1-5mm in diameter) for spinning. The parameters during spinning are set as follows: the spinneret voltage is 20kV, and the solution flow rate is 3mL / h; the formed fiber is ejected from the spinneret of the electrospinning equipment, the receiving distance between the receiving device and the spinneret is 10cm, the receiving device is equipped with double electrodes as the receiving electrodes, and the axes of...

Embodiment 3

[0050] In this embodiment, the nerve repair sleeve is prepared by the following method, which specifically includes the following steps:

[0051] (1) Dissolving caprolactone-glycolide copolymer (caprolactone content greater than 70%) in a mixture of chloroform and N,N-dimethylformamide with a volume ratio of 3:1 is prepared A solution with a mass volume concentration of 1%, and then stirred at 80° C. for 12 hours to obtain a polymer solution;

[0052] (2) The polymer solution is injected into the electrospinning equipment through a syringe (with a No. 5 stainless steel needle, 1-5mm in diameter) for spinning. The parameters during spinning are set as follows: the spinneret voltage is 30kV, and the solution flow rate is 1mL / h; the formed fiber is ejected from the spinneret of the electrospinning equipment, the receiving distance between the receiving device and the spinneret is 25cm, the receiving device is equipped with double electrodes as the receiving electrodes, and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com