Treatment method and treatment system of nickel-containing wastewater produced in anodic-oxidation hole sealing

A technology for anodizing and nickel wastewater, which is applied in the field of treatment methods and treatment systems used, can solve the problems of inconspicuous removal effect, inability to achieve nickel removal effect, weakened complexation ability, etc. The effect of contamination risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

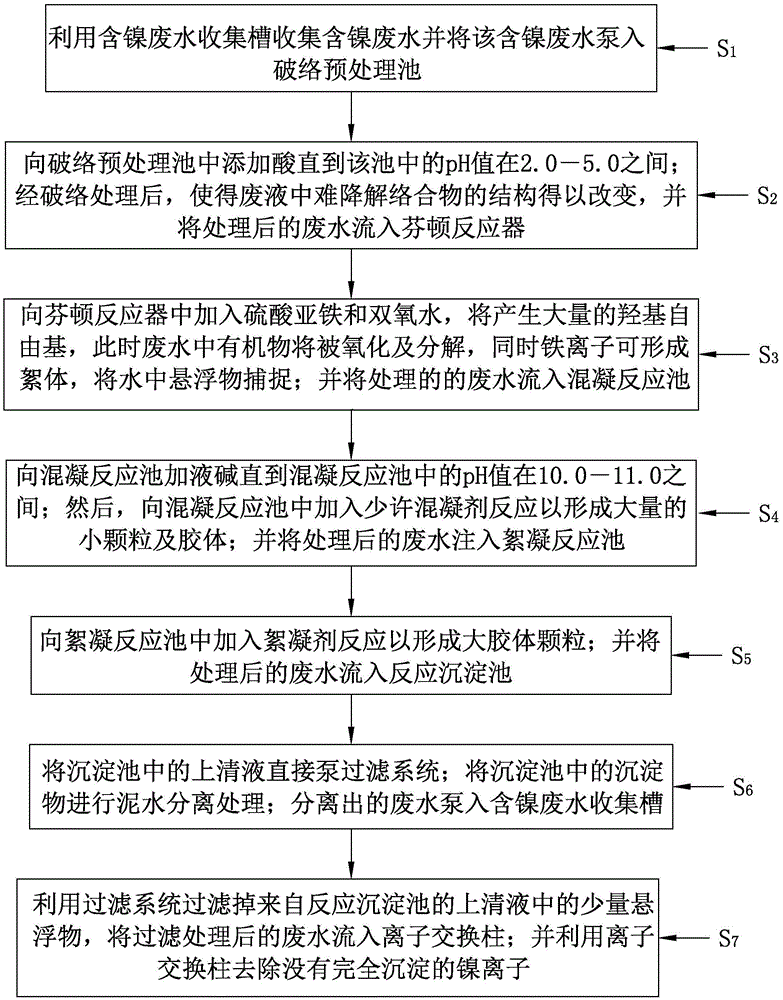

[0037] Such as figure 1 Shown, the process of the present invention is as follows:

[0038] Step S1, using the nickel-containing wastewater collection tank to collect the nickel-containing wastewater and pumping the nickel-containing wastewater into the network-breaking pretreatment tank.

[0039] Step S2, adding acid to the network-breaking pretreatment tank until the pH value in the network-breaking pre-treatment tank is between 2.0-5.0, and the reaction time is 60-90 minutes; after the network-breaking pretreatment, it is difficult to degrade in wastewater The structure of the complex is changed, and the treated primary wastewater flows into the Fenton reactor.

[0040] In step S3, ferrous sulfate and hydrogen peroxide are successively added to the Fenton reactor. During the Fenton reaction, the pH value of the incoming water is controlled to be between 2.0-6.0, and the process produces a large amount of hydroxyl radicals. The organic matter in the primary wastewater is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com