Environment-friendly surface treating agent used for galvanized steel sheet, galvanized steel sheet and manufacturing method for galvanized steel sheet

A surface treatment agent, technology of galvanized steel sheet, applied in the direction of coating, metal material coating process, polyurea/polyurethane coating, etc., can solve the problem that the corrosion resistance of steel sheet cannot be fully guaranteed, and the performance of galvanized steel sheet cannot meet the corresponding standards , the steel plate can not meet the performance requirements and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-3

[0061] The substrates of Examples 1-5 and Comparative Examples 1-3 all adopt 0.5mm galvanized steel sheets, and the weight of the zinc layer is 40 / 40g / m 2, first spray and clean the surface of the steel plate with a medium-alkalinity degreasing agent (pH: 11-12), then wash it with pure water to remove the residual alkaline components on the surface, and apply the environmental protection surface treatment agent for galvanized steel plate Drying is carried out at 80-180°C on the surface of the galvanized steel sheet to form a composite film with a thickness of 1-3 microns on the surface of the galvanized steel sheet.

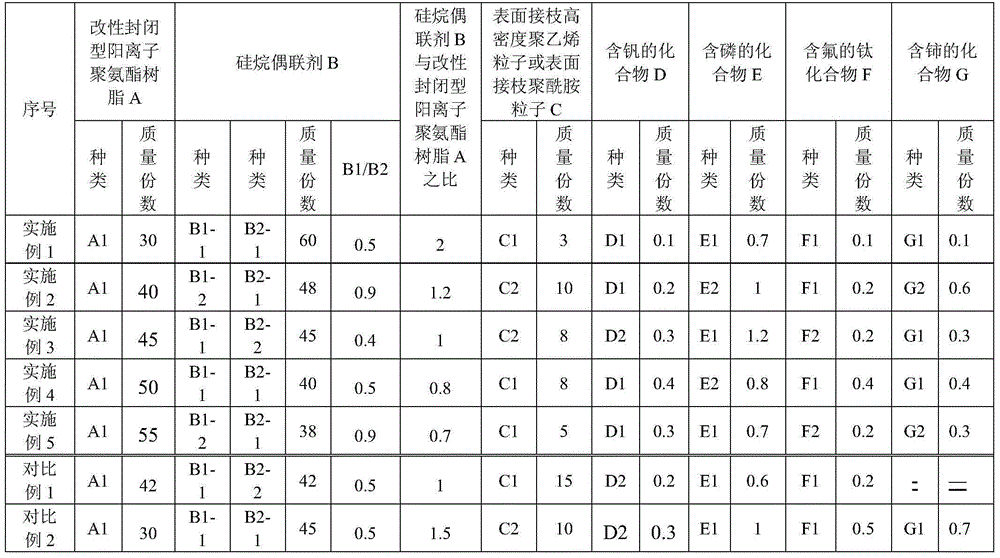

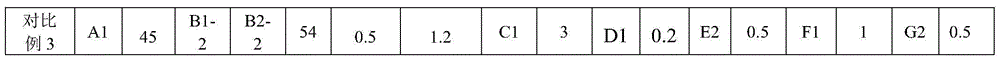

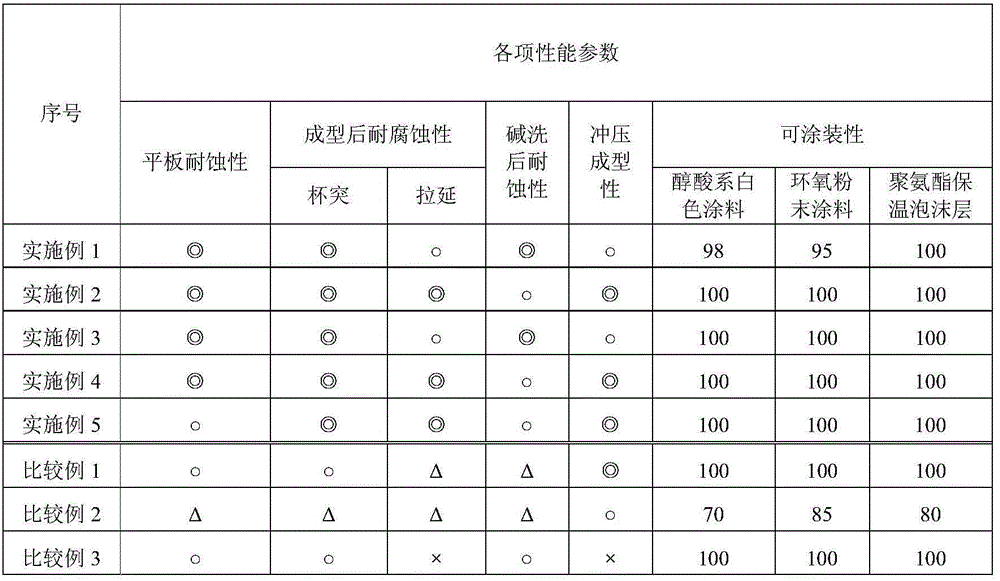

[0062] Table 1 lists the mass parts of each solid in the environmental protection surface treatment agent for galvanized steel sheets in Examples 1-5 and Comparative Examples 1-3.

[0063] Table 1.

[0064]

[0065]

[0066] *Note: A1 is modified closed cationic polyurethane resin; B1-1 is aminopropyltriethoxysilane, B2-1 is glycidoxypropyltrimethoxysilane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com