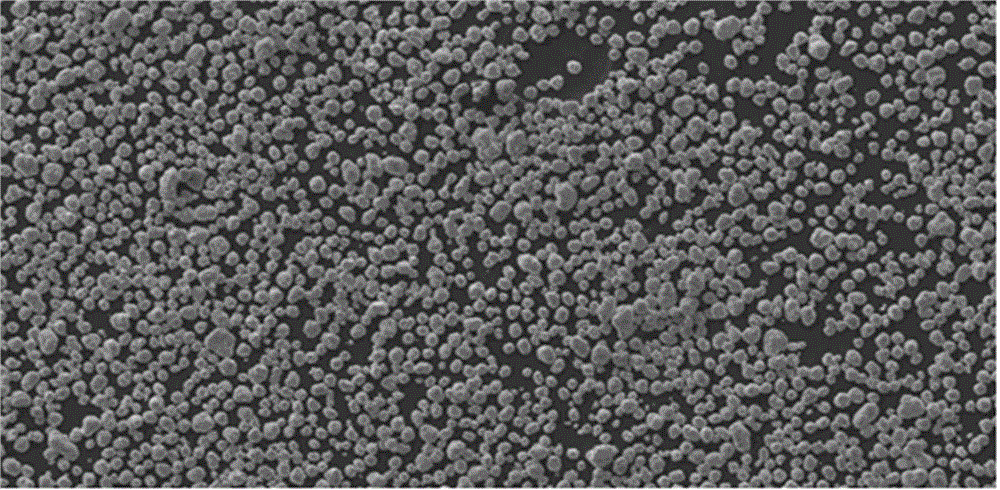

Preparation method of aluminum-coated spherical lithium nickel cobalt aluminum oxide cathode material for lithium-ion battery

A technology of nickel-cobalt-aluminate lithium and lithium-ion batteries, which can be used in battery electrodes, secondary batteries, circuits, etc., and can solve problems such as uneven distribution of particle elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of aluminum hydroxide colloid: Dissolve 0.1mol aluminum nitrate in deionized water to make a 2mol / L aqueous solution, slowly add 1mol / L ammonia water dropwise while stirring at room temperature to pH=9.0 to obtain precipitation. Rinse the precipitate with deionized water without aging, suction filter, wash, redisperse the precipitate with water, and add a certain amount of nitric acid at 60°C to control the pH value at 6.0 to make it peptized, and then seal and age at 85°C for 24 hours , to obtain clarified aluminum sol;

[0041](2) Preparation of nickel-cobalt-aluminum hydroxide precursor in the inner layer: mix the soluble salts of nickel and cobalt in a molar ratio of Ni:Co=0.8:0.15 to form a mixed salt solution with a concentration of 2mol / L; Sodium is prepared into a solution with a concentration of 4mol / L; ammonia water is prepared into a solution of 5mol / L; the molar ratio of the mixed salt solution and aluminum sol is: Ni:Co:Al=0.8:0.15:0.03, and...

Embodiment 2

[0046] (1) Preparation of aluminum hydroxide colloid: Dissolve 0.1mol aluminum nitrate in deionized water to make a 2mol / L aqueous solution, slowly add 1mol / L ammonia water dropwise while stirring at room temperature to pH=9.0 to obtain precipitation. Rinse the precipitate with deionized water without aging, suction filter, wash, redisperse the precipitate with water, and add a certain amount of nitric acid at 60°C to control the pH value at 6.0 to make it peptized, and then seal and age at 85°C for 24 hours , to obtain clarified aluminum sol;

[0047] (2) Preparation of nickel-cobalt-aluminum hydroxide precursor in the inner layer: mix the soluble salts of nickel and cobalt at a molar ratio of Ni:Co=0.815:0.15 to form a mixed salt solution with a concentration of 3mol / L; Sodium is prepared into a solution with a concentration of 3mol / L; ammonia water is prepared into a solution of 4mol / L; the molar ratio of the mixed salt solution and the aluminum sol is Ni:Co:Al=0.815:0.15:0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com