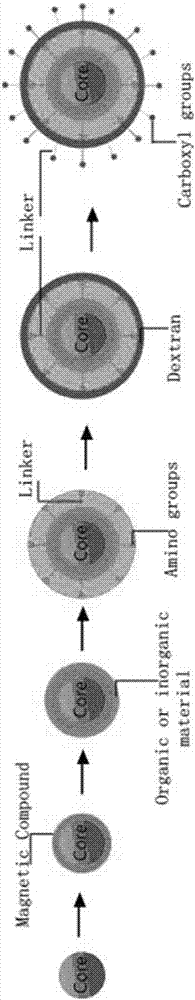

A preparation method and application of carboxyl magnetic beads coated with dextran

A technology of carboxyl magnetic beads and aldehyde dextran, which is applied in the biological field, can solve the problems of low coupling efficiency and high non-specific adsorption, and achieve the effect of increasing coverage and carboxyl content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

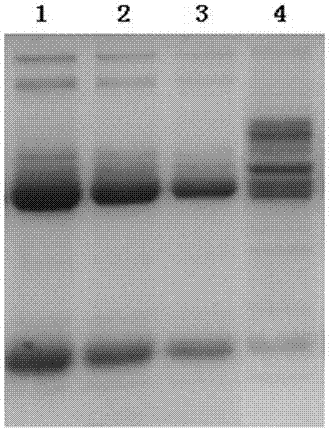

Examples

Embodiment 1

[0028] The preparation method of carboxyl magnetic beads (dextran and glutaraldehyde co-coupled to amino magnetic beads) in this example is as follows:

[0029] (1) Preparation of aldehyde dextran: Weigh 1 g of dextran (molecular weight: 70KDa), dissolve it in 20 mL of ultrapure water, add 0.1M NaIO4 to the solution to make the molar ratio of dextran to 1:2, Shake at 30°C for 2 hours in the dark to obtain aldehyde dextran; dialyze with ultrapure water for 8 hours or longer to remove unreacted NaIO4, vacuum freeze-dry the dialyzed solution to obtain a white solid that is aldehyde glucan Polysaccharides, keep away from light and refrigerate at 2-8°C;

[0030] (2) Graft the aldehyde dextran and glutaraldehyde obtained in step (1) onto the surface of amino magnetic beads at a mass ratio of 1:5 to prepare aldehyde magnetic beads, and mix the amino magnetic beads well, here The amino magnetic beads are MagpearL NH2, the average particle size is 1μm, the inner core is ferric oxide, ...

Embodiment 2

[0036] The preparation method of the carboxylated magnetic beads (using carboxylated dextran oxidation experiment) in this example is as follows:

[0037] (1) Carboxylation of dextran: Weigh 5 g of dextran (molecular weight: 70 KDa), dissolve it in 10 g of ultrapure water, add 0.08 g of sodium borohydride and 0.1 g of 50% NaOH to the solution, and keep away from light for no more than 25 Stir at ℃ for 4 hours, then add 3.9g 50% NaOH and 1.24g bromoacetic acid, shake at room temperature not exceeding 25℃ for 16 hours, then adjust the pH to neutral with doubled concentrated hydrochloric acid, and add ethanol to make the ratio of the two to 1: 1. Precipitate carboxylated dextran, dissolve the precipitate with 12mL ultrapure water, add 0.04g NaCL, add ethanol to make the ratio of the two 1:1, precipitate carboxylated dextran, repeat the above operation twice, Dissolve the precipitate in 12 mL of ultrapure water, add ethanol to precipitate carboxylated dextran, dry the precipitate ...

Embodiment 3

[0044] The preparation method of the carboxyl magnetic beads (formyl dextran grafted onto the amino magnetic beads alone) in this example, the steps are as follows:

[0045] (1) Oxidized dextran: Weigh 1 g of dextran (molecular weight: 70KDa), dissolve it in 20 mL of ultrapure water, add 0.1M NaIO4 to the solution to make the molar ratio of dextran to 1:2, avoid Light shock for 2 hours to obtain aldehyde dextran; dialyze with ultrapure water for 8 hours or longer to remove unreacted NaIO4, vacuum freeze-dry the dialyzed solution to obtain a white solid that is aldehyde dextran, Keep away from light and refrigerate at 2-8°C;

[0046] (2) Graft the aldehyde-dextran obtained in step (1) onto the surface of amino magnetic beads to prepare aldehyde-based magnetic beads: mix the amino magnetic beads thoroughly, absorb 1 mL (10 mg / mL) of magnetic beads, magnetically separate them, and use ultra- Wash the magnetic beads 2-3 times with pure water, magnetically separate, and discard th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com