Biodegradable agricultural mulching film and preparation method thereof

An agricultural mulch film and biodegradable technology, applied in the field of film materials, can solve problems such as low mechanical strength, poor moisturizing performance, and development obstacles, and achieve the effect of improving mechanical strength and moisturizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The invention provides a method for preparing a biodegradable agricultural mulch film, comprising the following steps:

[0064] The raw materials are sequentially melt blended, granulated and blow molded to obtain a biodegradable agricultural mulch film;

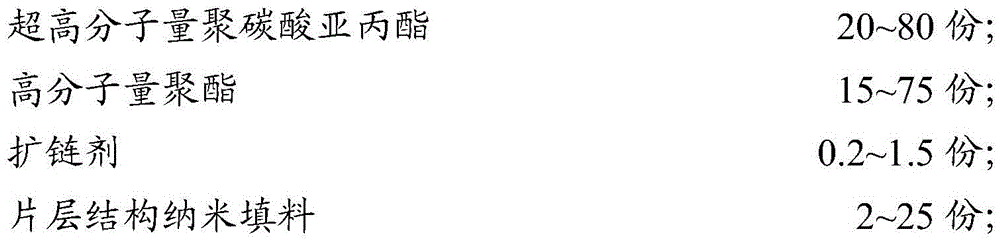

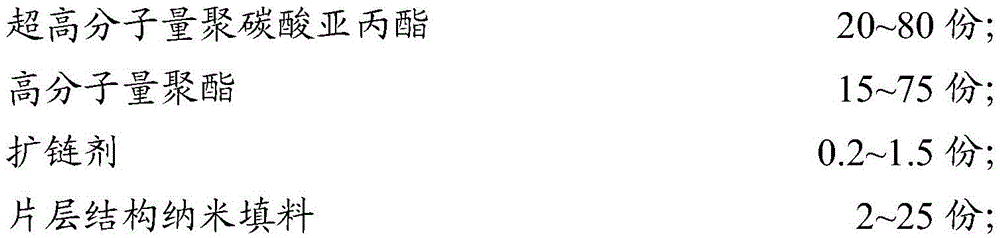

[0065] The raw materials include 20-80 parts by weight of ultra-high molecular weight polypropylene carbonate, 15-75 parts by weight of high-molecular-weight polyester, 0.2-1.5 parts by weight of chain extender and 2-25 parts by weight of nano-fillers with lamellar structure;

[0066] The number-average molecular weight of described ultra-high molecular weight polypropylene carbonate ≥ 300kDa; Described high molecular weight polyester comprises poly(butylene adipate-butylene terephthalate) and / or carbon dioxide-based poly( Carbonate-ether) type polyurethane; the number average molecular weight of the high molecular weight polyester is 80-150kDa.

[0067] In the preparation method provided by the invention, the raw ma...

Embodiment 1

[0076] Preparation of Carbon Dioxide Based Poly(carbonate-ether) Polyurethane

[0077] Add 32kg propylene oxide, 50g Co-Zn double metal cyanide as a catalyst, 0.9L dry polypropylene glycol with a molar mass of 350g / mol, stir for 1h, pressurize carbon dioxide to 5MPa, and heat up to After reacting for 6 hours at 75°C, the reaction product was precipitated and separated to obtain carbon dioxide-based poly(carbonate-ether) glycol.

[0078] Using gel permeation chromatography (GPC) analysis, polymer molecular weight 2200Da, using hydrogen nuclear magnetic resonance spectrum analysis (H 1 -NMR) copolymer ether segment content 25%.

[0079] Add 70mol of terephthalic acid, 30mol of adipic acid, 100mol of butanediol and 9g of tetrabutyl titanate into a 50L polymerization reactor, under nitrogen protection, and react at 235°C. When the water output reaches the theoretical water output, the temperature is raised to 255°C. The pressure was reduced to 50Pa, and the reaction was continue...

Embodiment 2

[0082] Preparation of agricultural mulch

[0083] 20 parts by weight of PPC (number average molecular weight 320kDa, weight average molecular weight 950kDa), 70 parts by weight of PBAT (number average molecular weight 85kDa, weight average molecular weight 162kDa), 0.2 parts by weight of free radical scavenger UV-622, 0.3 parts by weight of ultraviolet absorber UV-571, 0.5 parts by weight of BASF epoxy chain extender ADR-4370, 0.3 parts by weight of erucamide and 8.7 parts by weight of nano-montmorillonite (diameter-thickness ratio: 130, thickness: 30nm) are mixed in a mixer Uniform, granulate with twin-screw extruder at 120°C-180°C, after cooling and drying, use conventional single-screw film blowing equipment to blow a film with a thickness of 0.006mm at 100°C-150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com