Metronidazole modified graphene oxide composite material and preparation method thereof

A composite material and graphene technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of low utilization rate of carboxyl groups, difficulty in graphene modification, and inability to fully utilize the characteristics of graphene materials, and achieve the effect of reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of metronidazole modified graphene oxide composite material, comprises the following steps:

[0028] (1) Take 0.8g flake graphite (GR) and 24mL concentrated H 2 SO 4 Put it into a three-neck flask for ultrasonic dispersion for 20min, then immerse the mixture in an ice-water bath and stir for 30min, then slowly add 1gNaNO 3 Add 4.8gKMnO after reacting for 30min 4 React for 2 hours, move the reactant into an oil bath at 39°C and stir for 2.5 hours, then add 41 mL of distilled water, and raise the reaction temperature to 95°C, react for 1.5 hours, and then add 10% H 2 o 2 120mL was reacted for 1h, washed with 100mL of HCl (0.5mol / L), centrifuged, ultrasonicated, dried, and ground to prepare graphene oxide (GO);

[0029] (2) Add 8g of maleic anhydride (MA) into the three-necked flask, put it into an oil bath at 75°C and stir to dissolve it, add 0.4g GO to the dissolved MA under stirring and react for 3h, then add to the three-necked flask 1...

experiment example

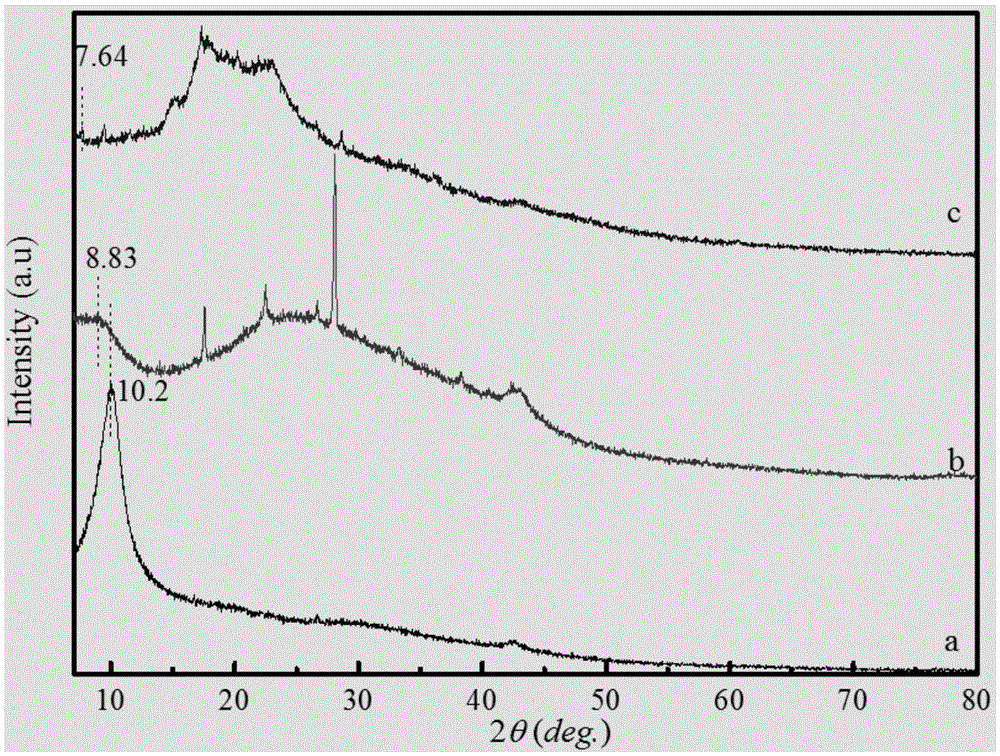

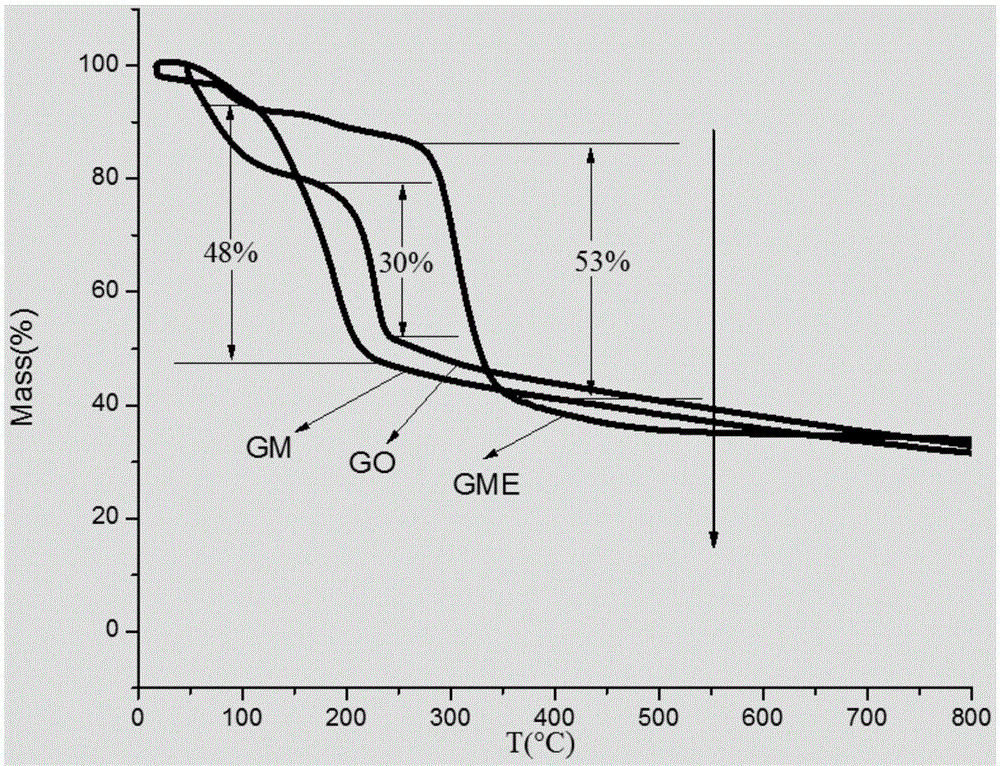

[0032] The carboxyl group content on the GO sheet was increased by MA modification of GO, and the carboxyl group was used to react with the hydroxyl group on metronidazole to prepare the composite material GME. The success of modification and grafting was analyzed by FTIR, XRD, TGA, and XPS, and the success of grafting was analyzed by EIS. Analysis of composite material additives on the anti-corrosion performance of epoxy resin coatings. The experimental results show that the modified and grafted GO has excellent anti-corrosion performance in epoxy resin, and the toughness of the composite material is improved.

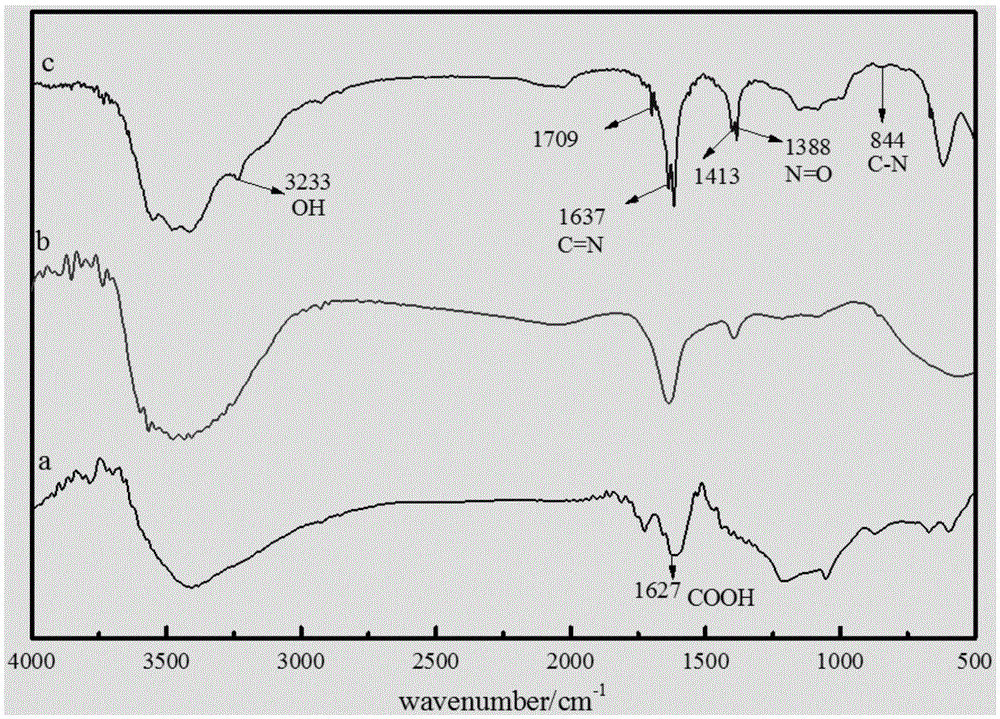

[0033] (1) Infrared spectral analysis

[0034] The infrared spectra of graphene oxide (GO), maleic anhydride modified graphene oxide (GM) and metronidazole modified graphene oxide composite (GME) are shown in figure 1 . figure 1 The middle curve a is the characteristic absorption vibration peak of GO, and the oxygen-containing functional groups contained are -OH (33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com