High-voltage fast recovery diode chip employing gradient field limiting ring and production technology of high-voltage fast recovery diode chip

A recovery diode and production process technology, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of large difference in electric field distribution, large forward conduction voltage, and easy burnout of the pole tube chip, so as to achieve extended life, The effect of increasing the withstand voltage, enhancing the stability and reliability of the withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

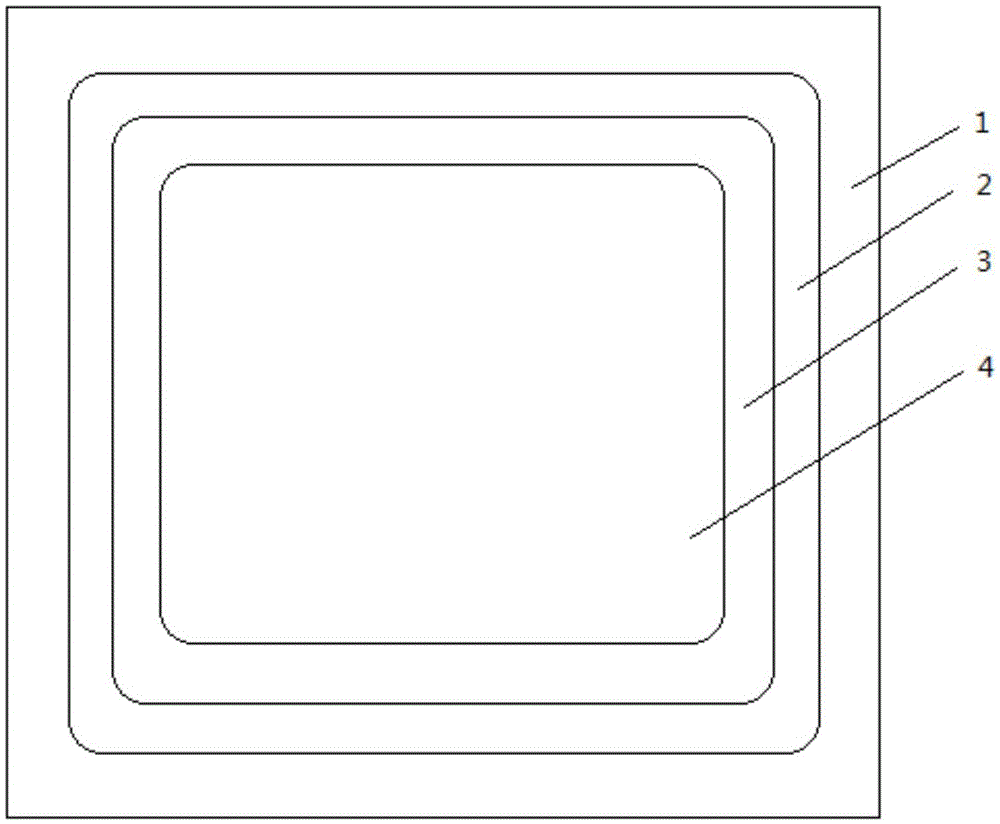

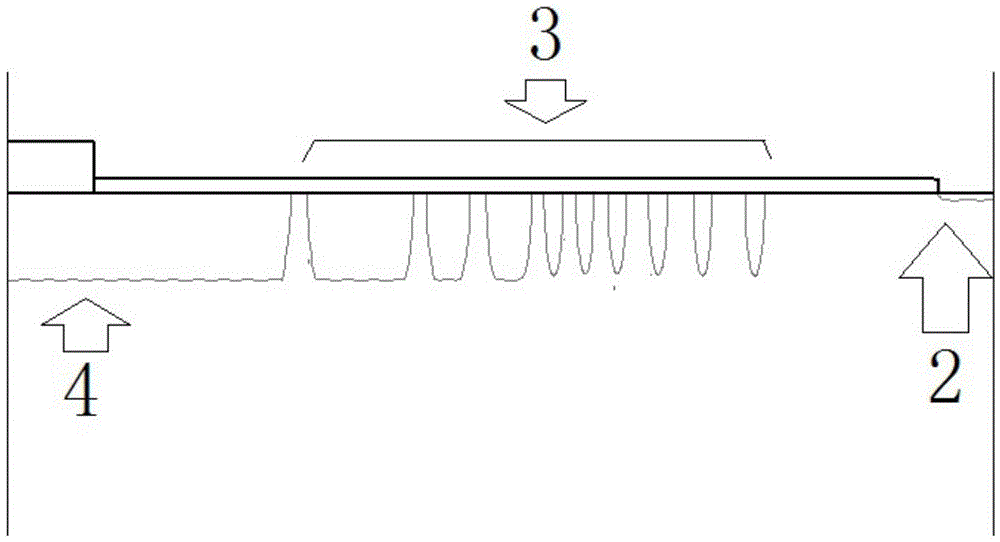

[0063] Such as figure 1 As shown, a high-voltage fast recovery diode chip with gradient electric field confinement ring includes a chip 1, an N+ cut-off ring 2, a gradient electric field confinement ring 3 and a P+ anode 4, and the chip 1 is a fast recovery diode chip; figure 2 As shown, the electric field confinement ring of gradient electric field confinement ring 3 has nine layers, and by design, the width of the electric field confinement ring is gradually reduced from 56 microns to 10 microns from the P+ anode to the N+ stop ring on the edge of the chip, and the distance between the electric field confinement rings is gradually changed. Larger, gradually increasing from 9 microns to 18 microns, the depth of the gradient electric field confinement ring 3 is the same as that of the P+ anode, and the depth is 40 microns. Such as Figure 4 As shown, the high-voltage potential linearly decreases from the P+ anode to the edge of the chip and the electric field is uniformly di...

Embodiment 2

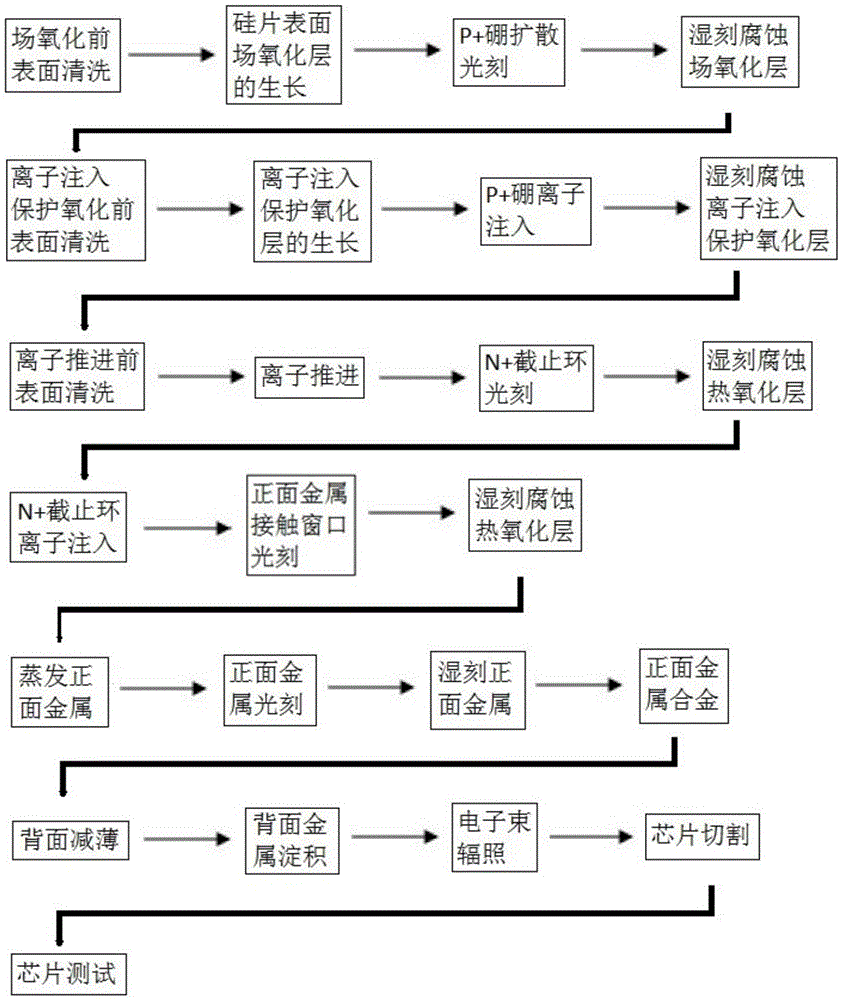

[0106] A production process of a high-voltage fast recovery diode chip with a gradient electric field confinement ring, the steps of which are as follows:

[0107] 1) Surface cleaning before field oxidation:

[0108] Configure a hydrofluoric acid solution, which is obtained by mixing a solution with a volume ratio of water:hydrofluoric acid=6:1, and the mass concentration of the hydrofluoric acid solution is 40%;

[0109] Configure No. 1 solution, which is obtained by mixing ammonia water: hydrogen peroxide solution: water = 1:1:5-1:2:7 in volume ratio, and the concentration of ammonia water is 27%;

[0110] Configure No. 2 solution, which is obtained by mixing the volume ratio of hydrogen chloride: hydrogen peroxide solution: water = 1:1:6-1:2:8. The mass concentration of hydrogen chloride is 37%, and the mass concentration of hydrogen peroxide solution is 30%. ;The cleaning sequence is as follows:

[0111] a. Soak the silicon wafer with hydrofluoric acid solution for 30s, ...

Embodiment 3

[0138] Embodiment 3 is basically the same as Embodiment 1, except that the backside thinning method in step 20) is wet etching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com