Resource utilization method of livestock excrement water-soluble manure production wastewater for culturing dunaliella

A technology for livestock and poultry manure and waste water production, which is applied in microorganism-based methods, biochemical equipment and methods, and methods for supporting/immobilizing microorganisms, etc., can solve problems such as resource waste and pressure, and achieve cost savings and reduction of pollutant concentrations. , the effect of saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this example, the treated chicken manure water-soluble fertilizer production wastewater has a COD of 823.6 mg / L, a TN of 2979.3 mg / L, and a NH 3 -N concentration is 2166.3mg / L, TP concentration is 9.6mg / L.

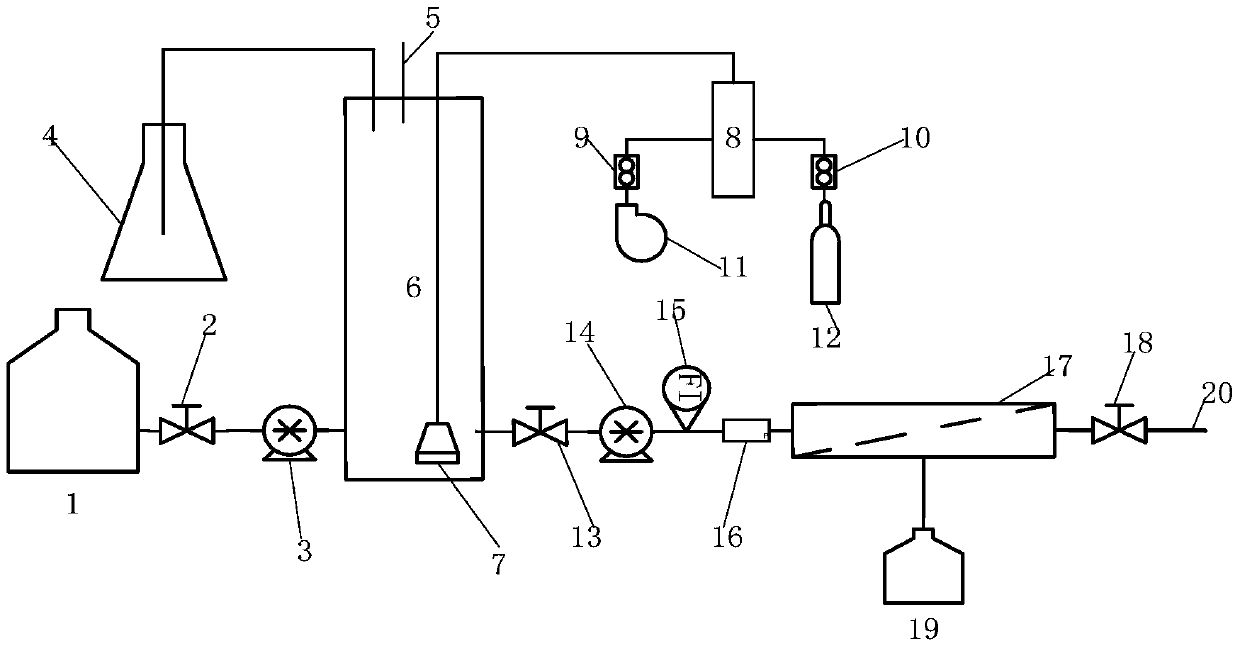

[0049] Such as figure 1 , the equipment used for resource utilization of chicken manure water-soluble fertilizer production wastewater includes a photobioreactor 6, an ultrafiltration unit, a microalgae seed liquid culture device 4, and an air intake unit;

[0050] The treated chicken manure water-soluble fertilizer production wastewater is stored in the livestock and poultry manure water-soluble fertilizer production wastewater storage tank 1, and is connected to the bottom of the photobioreactor 6 through the first diaphragm pump 3, the livestock and poultry manure water-soluble fertilizer production wastewater inlet 2 and pipelines , the wastewater inlet is about 10 cm away from the bottom of the reactor, and the microalgae seed culture device 4 is a triangul...

Embodiment 2

[0065] In this example, the treated chicken manure water-soluble fertilizer production wastewater has a COD of 869.4 mg / L, a TN of 2892.3 mg / L, and a NH 3 -N concentration is 2151.2mg / L, TP concentration is 9.5mg / L.

[0066] Processing steps:

[0067] 1. Through the water pump, pump 5L of livestock and poultry manure water-soluble fertilizer production wastewater from the wastewater inlet to the main body of the reactor, add 135L of distilled water, and finally NH 3 -N content was 100.6 mg / L. ;

[0068] 2. Add nutrient salts to NaH in sequence to the wastewater in the reactor 2 PO 4 2H 2 O15mg / L, CaCl 2 2H 2 O40mg / L, MgSO 4 ·7H 2 O1250mg / L, ferric citrate 4mg / L. Set the culture light intensity to 2000 lux, the ratio of light to dark cycle L:D=12:12, each cycle is 12 hours respectively.

[0069] 3. Use NaCl solution to adjust the salinity value of the wastewater to 170, and then use 1mol / L sodium hydroxide solution to adjust the pH value to 8.5. Add microalgae seed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com