Water system energy storage battery based on (TiO)x(P2O7)y cathode and manganese-based oxide anode

A manganese-based oxide and battery technology, applied in the field of electrochemical energy, can solve the problems of low power density and energy density of titanium salt materials, little improvement in battery performance, and no substantial effect, etc. The effect of high consistency and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation and M of the positive / negative pole of the present invention x mn y o z -((TiO) x (P 2 o 7 ) y The assembly steps of the system full battery are as follows:

[0025] (1) M x mn y o z Preparation of positive electrode

[0026] with M 2 CO 3 with MnO 2 As the raw material, the M x mn y o z Cathode material. The general formula of the manganese-based alkali metal salt compound is M x mn y o z , wherein M is at least one of Li, Na, K, x:y:z=0~2.0:1.0~3.0:4.0, wherein M x mn y o z The mass in M x mn y o z The proportion in / AC is 50wt%~100wt%;

[0027] (2)((TiO) x (P 2 o 7 ) y Preparation of negative electrode

[0028] Using titanium salt and ammonium dihydrogen phosphate as raw materials, the titanyl phosphate precursor is synthesized in a hydrothermal reaction kettle according to the metering ratio, and then sintered under high temperature conditions to form a titanyl phosphate negative electrode material. The chemical formula of ...

Embodiment example 1

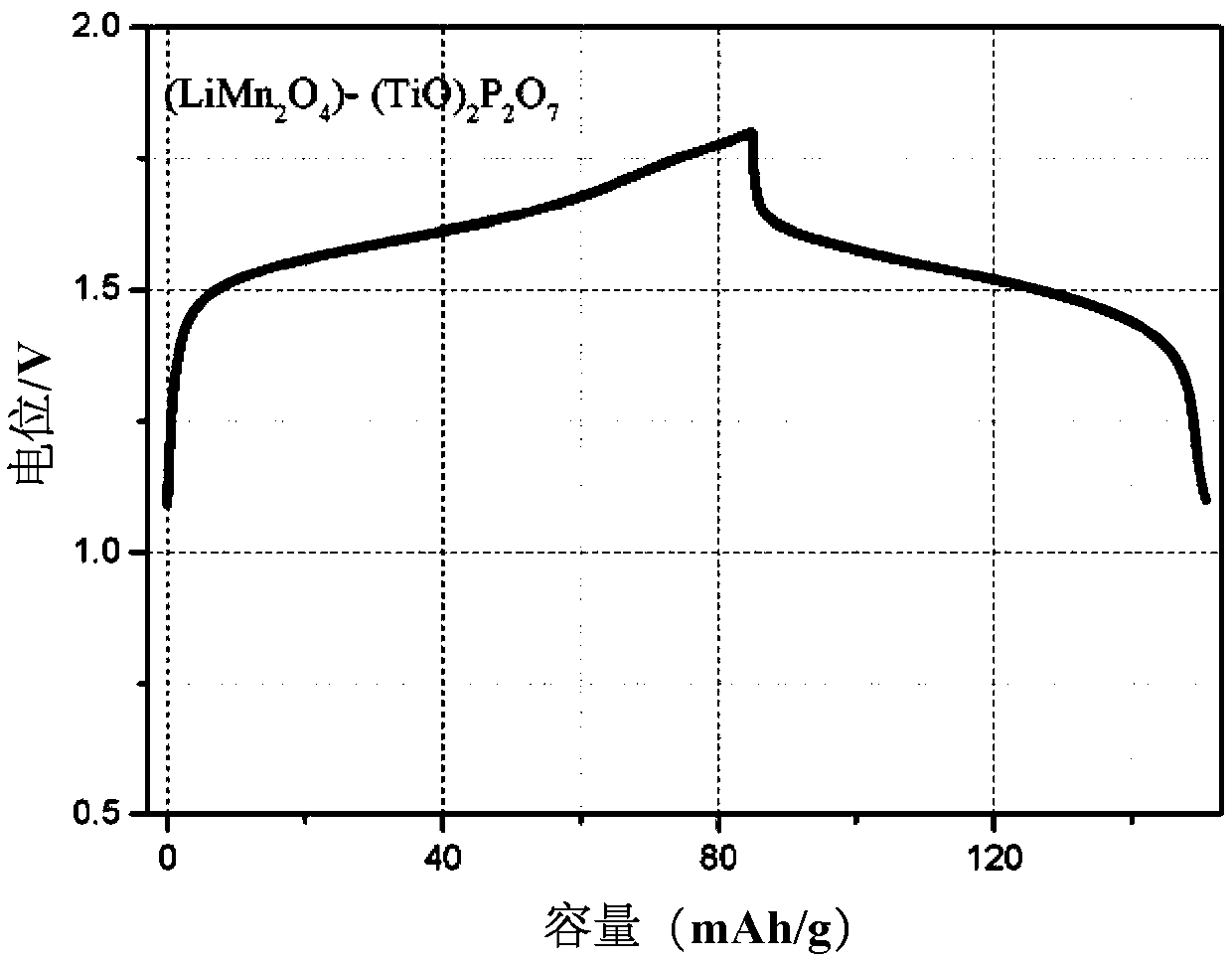

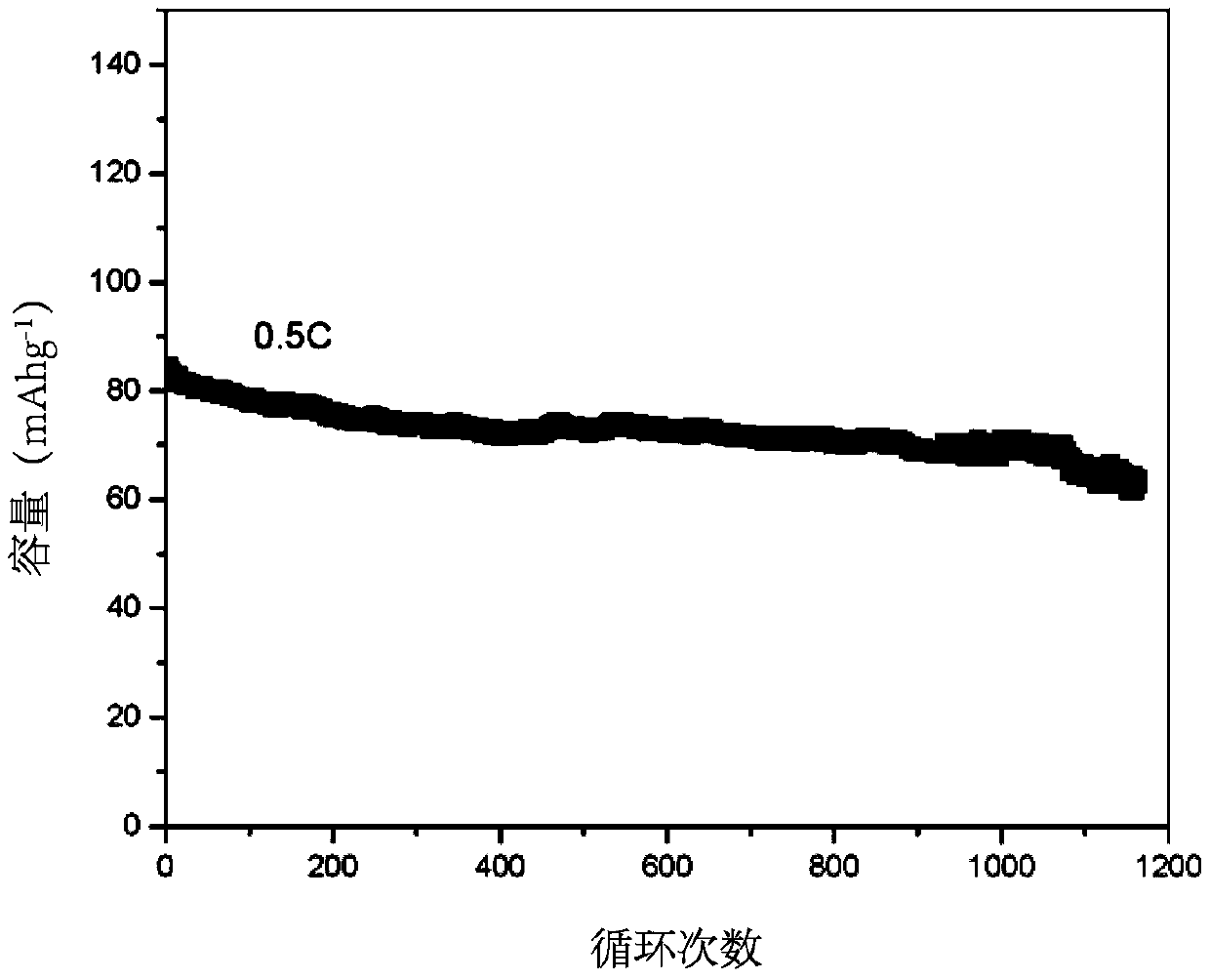

[0032] Implementation Case 1: LiMn 2 o 4 -(TiO) 2 P 2 o 7 System full battery assembly and its performance

[0033] Positive electrode uses LiMn 2 o 4 According to the mass ratio of active material: conductive agent: binder = 8:1:1, add solvent and mix evenly, after drying, press on the current collector; the negative electrode uses (TiO) 2 P 2 o 7 / AC((TiO) 2 P 2 o 7 : AC=(3~5):1) Materials, according to the mass ratio of active material: conductive agent: binder = 7:2:1, add solvent and mix evenly, after drying, press on the current collector; the diaphragm adopts no Spinning diaphragm, electrolyte use 1mol / LLi 2 SO 4 aqueous solution to assemble a full battery. The battery is charged and discharged in the 1.1-1.8V window, and the voltage platform is 1.5V at a rate of 0.5C, and 65mAh / g is retained after 1200 cycles. The full battery system has good cycle stability;

[0034] In this implementation case, the Li 2 SO 4 The electrolyte in aqueous solution can us...

Embodiment example 2Na0

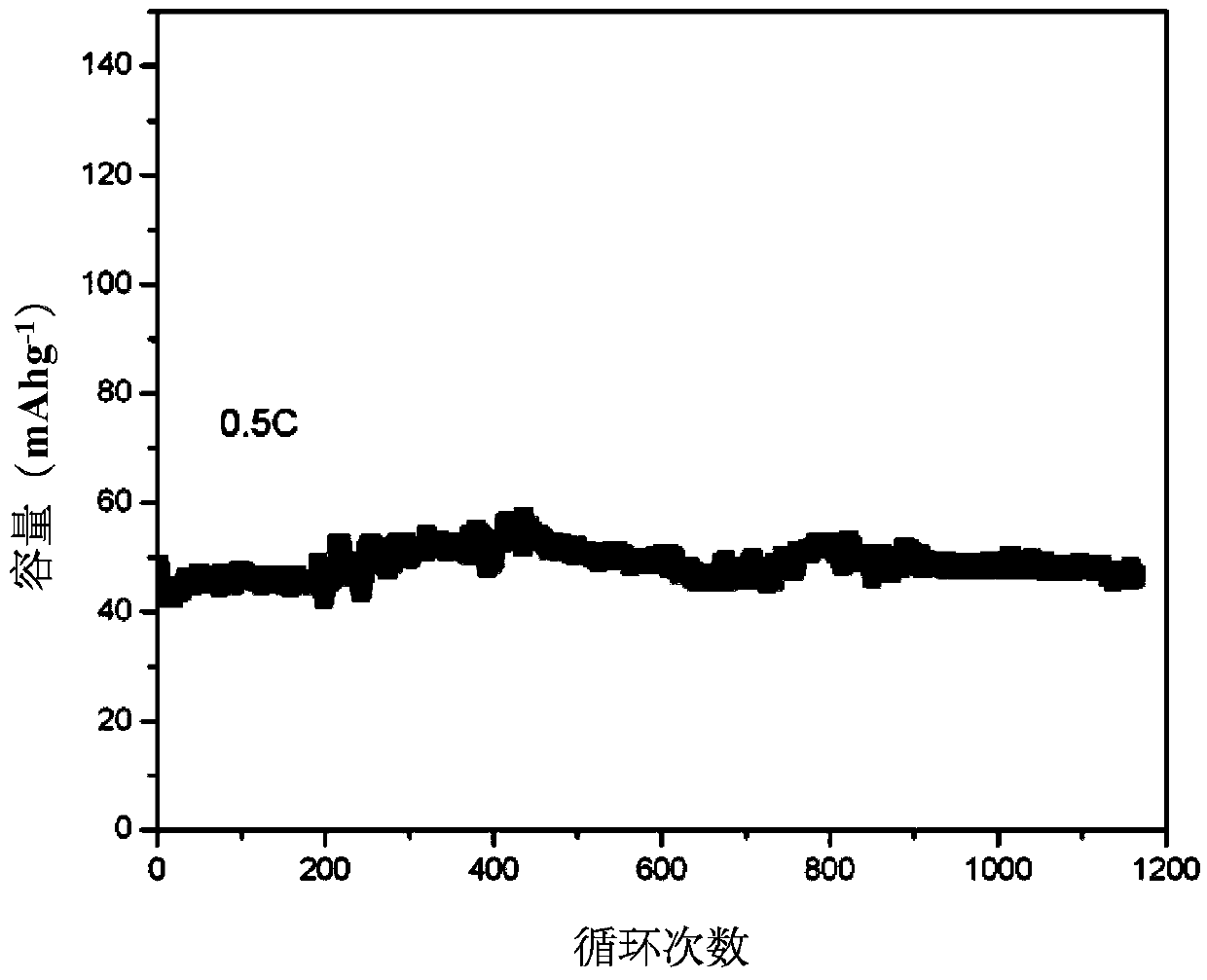

[0035] Implementation Case 2Na 0.44 MnO 2 -(TiO) 2 P 2 o 7 System full battery assembly and its performance

[0036] Positive electrode uses Na 0.44 MnO 2 According to the mass ratio of active material: conductive agent: binder = 8:1:1, add solvent and mix evenly, after drying, press on the current collector; the negative electrode uses (TiO) 2 P 2 o 7 / AC((TiO) 2 P 2 o 7 : AC=3~5:1) material, according to the active material ((TiO) 2 P 2 o 7 The ratio to activated carbon is 4:1): conductive agent: binder = 7:2:1 mass ratio, add solvent and mix evenly, after drying, press on the current collector; the separator is made of non-woven fabric, and the electrolyte uses 1mol / LNa 2 SO 4 aqueous solution to assemble a full battery. The battery is charged and discharged in the 1.0-1.8V window, and 45mAh / g is retained after 1200 cycles at a rate of 0.5C. The full battery system has good cycle stability;

[0037] In this implementation case, the Na used 2 SO 4 The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com