Lithium ion anode and cathode materials atmosphere immersive sintering process and related sintering device

A technology of sintering equipment, positive and negative electrodes, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of reducing the protective effect of the atmosphere or the reactivity, poor material quality and stability, and large differences between the upper and lower surfaces. Changes in temperature gradient, which are beneficial to anti-suck back and increase the effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

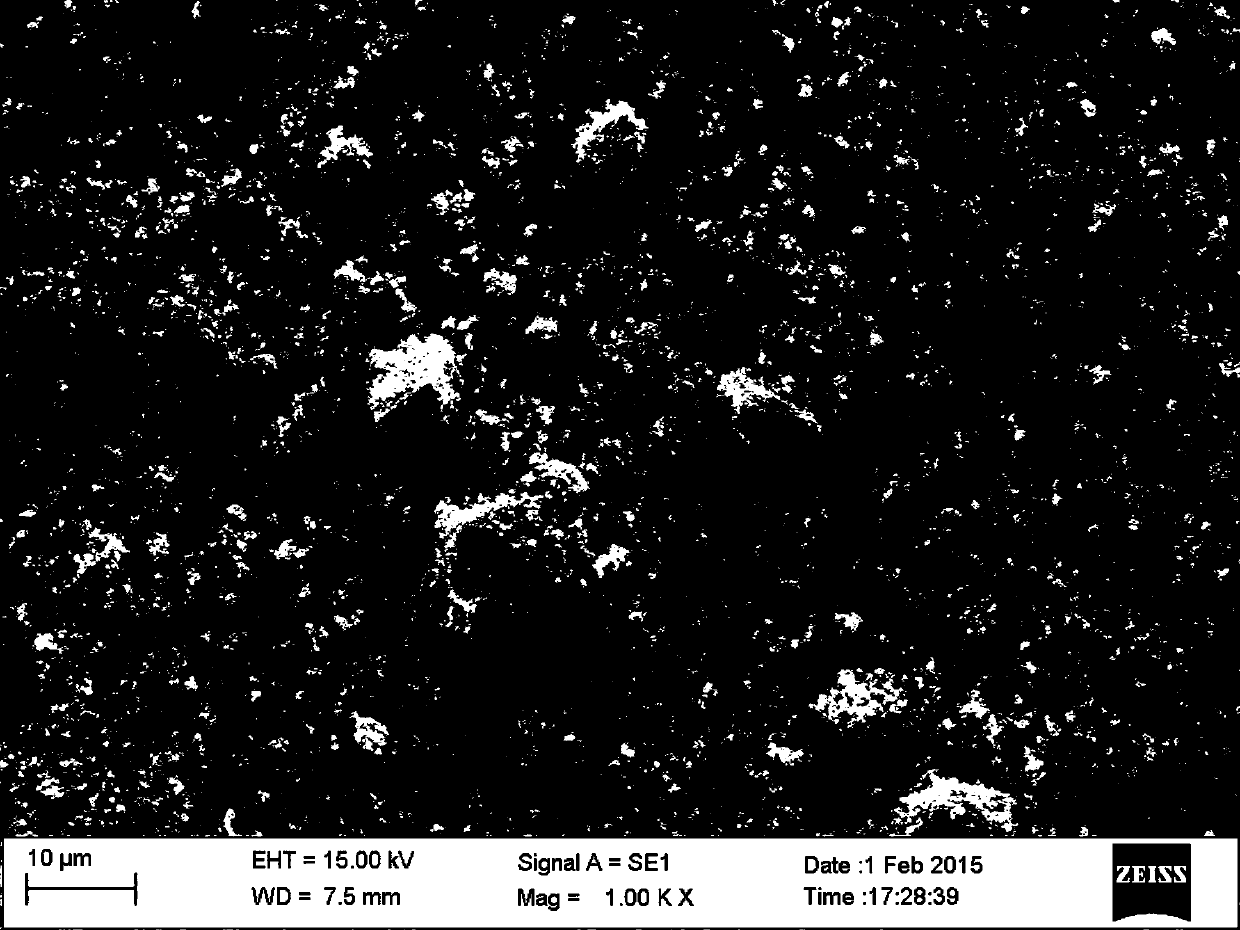

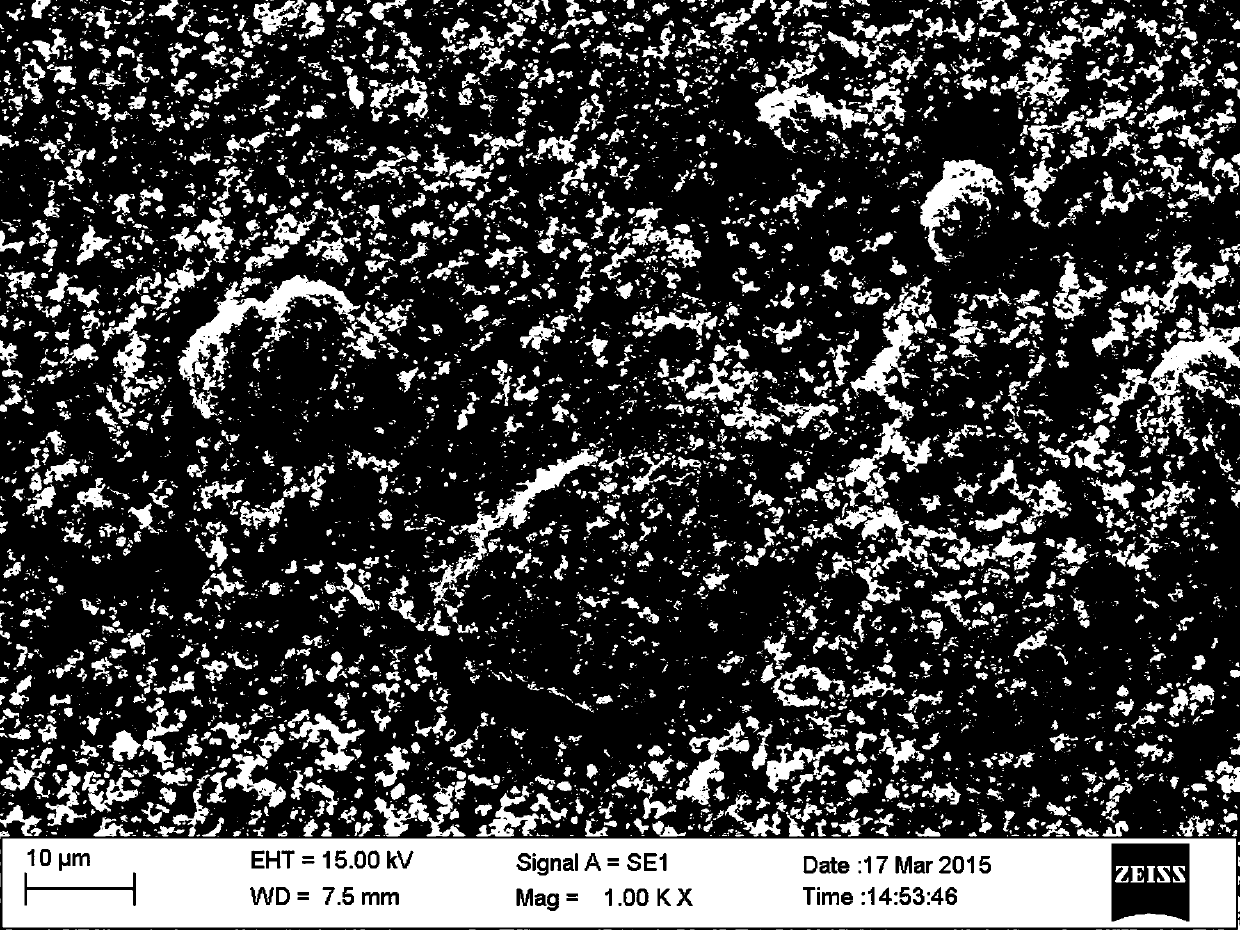

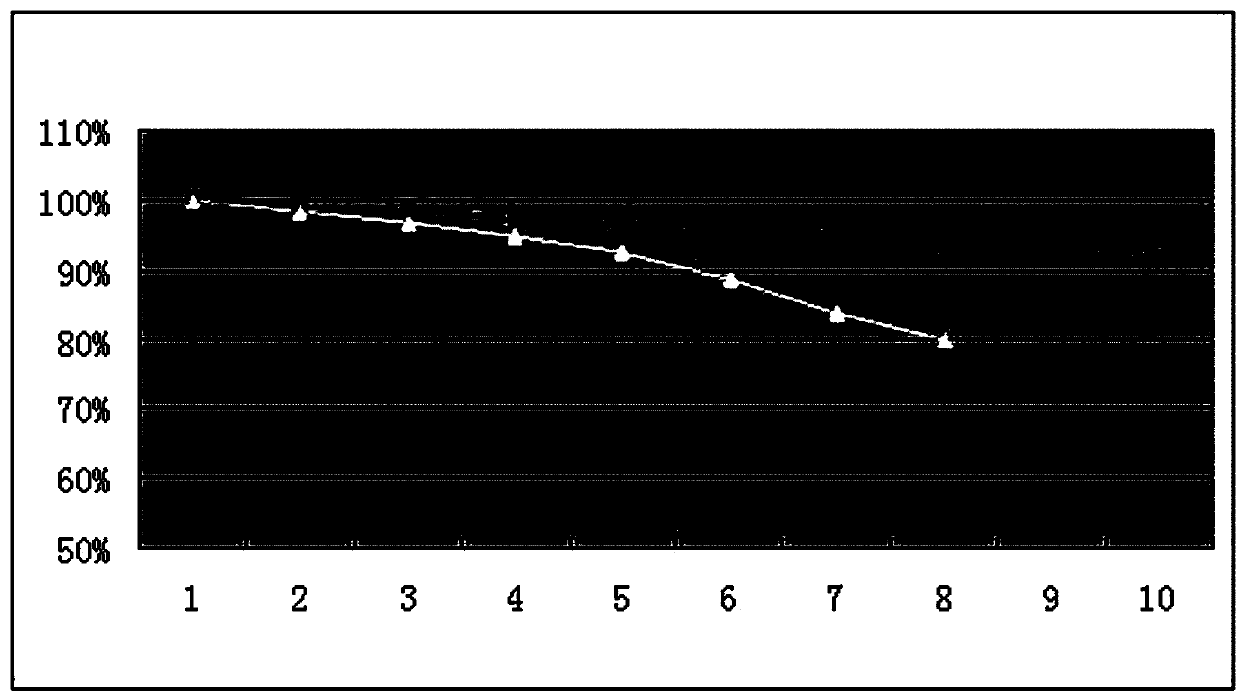

[0031] Immersion sintering of nickel cobalt lithium manganese oxide material under oxygen atmosphere:

[0032] Add the precursor mixture of nickel hydroxide, cobalt manganese and lithium carbonate materials into the spheroidizer, granulate into balls, and then screen with a screen of 100-200 to obtain the particle precursor material with good consistency. Finally, the product precursor mixture will be obtained. Open the immersion sintering furnace, the upper part of the sintering furnace is a spherical cavity with a radius of 18cm, and the lower part is a spherical cavity with a radius of 21cm; The mixture of nickel hydroxide, cobalt, manganese and lithium carbonate, which is a lithium manganate material, is spread on the expansion plate with alternating concave and convex, so that the thickness of the material is controlled uniformly, and the surface of the material is equal to the upper surface of the ventilation tower;

[0033] The upper and lower symmetrical expansion pane...

Embodiment 2

[0037] Immersion sintering of lithium iron phosphate material under nitrogen atmosphere:

[0038] Add the precursor mixture of iron phosphate and lithium carbonate materials into the spheroidizer, granulate into balls, and then use the sieve 100-200 to screen to obtain the particle precursor material with good consistency, and finally obtain the product precursor mixture, soak the gas powder Open the type sintering furnace, the upper part of the sintering furnace is a spherical cavity with a radius of 18cm, and the lower part is a spherical cavity with a radius of 21cm; take out the upper and lower symmetrical expansion panels, remove the upper expansion panel, and place the lithium iron phosphate The material is a mixture of iron phosphate, glucose and lithium carbonate, which is laid flat on the expanding plate with alternating concave and convex, so that the thickness of the material is controlled uniformly, and the surface of the material is equal to the upper surface of th...

Embodiment 3

[0043] Immersion sintering of carbon-coated lithium titanate anode material under nitrogen atmosphere:

[0044] Add the precursor mixture of titanium dioxide and lithium carbonate materials into the spheroidizer, granulate into balls, and then use a screen of 100-200 to screen to obtain the particle precursor material with good consistency. Finally, the product precursor mixture will be obtained, and the gas powder soaked The sintering furnace is opened, the upper part of the sintering furnace is a spherical cavity with a radius of 18cm, and the lower part is a spherical cavity with a radius of 21cm; take out the upper and lower symmetrical expansion panels, remove the upper expansion panel, and put the raw material of the negative electrode material The mixture of lithium carbonate and titanium dioxide is laid flat on the expanding plate with alternating concave and convex, so that the thickness of the material is controlled to be uniform, and the surface of the material is eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com