Preparation method for dimethyl sulfone

A technology of dimethyl sulfone and dimethyl sulfide, applied in the field of preparation of dimethyl sulfone, can solve the problems of serious equipment corrosion, need to be further improved, unfavorable environmental protection and the like, and achieves low corrosion degree and high oxidant effect. Utilization, high conversion rates and the effectiveness of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

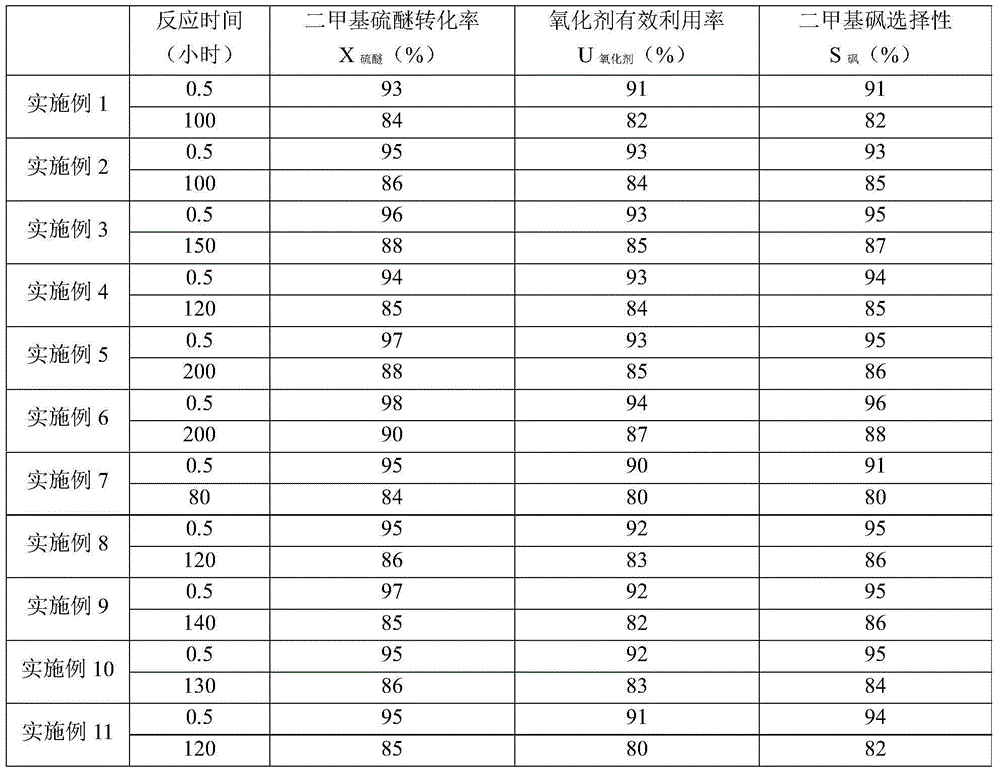

Examples

preparation example Construction

[0009] The invention provides a method for preparing dimethyl sulfone, which comprises the steps of passing a liquid mixture through a catalyst bed filled with at least one titanium-silicon molecular sieve in a fixed-bed reactor under oxidation reaction conditions to obtain A mixture comprising dimethyl sulfone, the liquid mixture comprising dimethyl sulfide and at least one peroxide.

[0010] According to the method of the present invention, the peroxide refers to a compound containing -O-O-bonds in its molecular structure, which may be hydrogen peroxide and / or organic peroxides (such as hydroperoxides and peracids). Specific examples of the peroxide may include, but are not limited to, hydrogen peroxide, t-butyl hydroperoxide, cumene peroxide, cyclohexyl hydroperoxide, peracetic acid, and peroxypropionic acid. Preferably, the oxidizing agent is hydrogen peroxide, which can further reduce the separation cost. The hydrogen peroxide may be hydrogen peroxide commonly used in th...

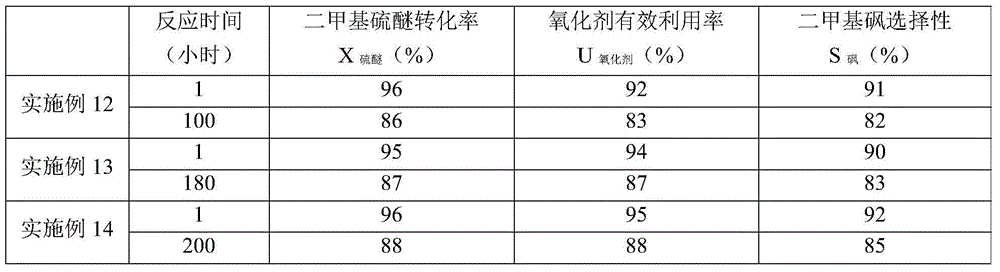

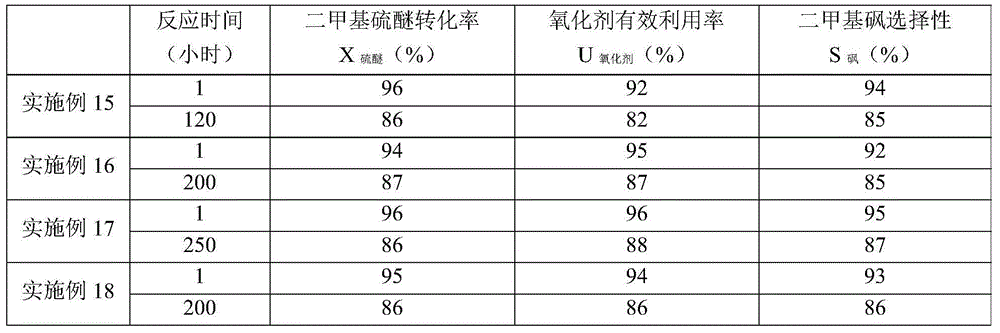

Embodiment 13、14 and 16-18

[0049] Embodiment 13, 14 and 16-18 adopt the following method to measure the activity of catalyst:

[0050] Catalyst, 36% by weight of ammonia water (as NH 3 meter), 30% by weight of hydrogen peroxide (as H 2 o 2 ), tert-butanol and cyclohexanone by mass ratio = 1:7.5:10:7.5:10 and then stirred and reacted at 80°C under atmospheric pressure for 2h, filtered the reactant, and analyzed the obtained liquid phase by gas chromatography The composition of the catalyst is analyzed, and the conversion rate of cyclohexanone is calculated by the following formula and used as the activity of the catalyst,

[0051] The conversion rate (%) of cyclohexanone=[(the molar amount of cyclohexanone added−the molar amount of unreacted cyclohexanone) / the molar amount of cyclohexanone added]×100%.

Embodiment 1

[0054] (1) Mix titanium-silicon molecular sieve TS-1 with silica sol (silicon oxide content is 30% by weight) and water, wherein the weight ratio of titanium-silicon molecular sieve TS-1, silica sol in terms of silicon oxide and water is 1 :0.2:1.5. The obtained mixture was granulated by rolling balls, and the obtained wet granules were calcined at 550° C. for 5 hours to obtain a catalyst (referred to as C1) with a volume average particle diameter of 200 μm. Wherein, in the catalyst, the content of titanium-silicon molecular sieve TS-1 is 80% by weight.

[0055] (2) Packing the catalyst prepared in step (1) in an equal-diameter fixed-bed reactor to form a catalyst bed. Dimethyl sulfide, hydrogen peroxide (as 30% by weight hydrogen peroxide), and methanol were mixed to form a liquid mixture. The liquid mixture is then fed into a fixed bed reactor and passed through a catalyst bed. Among them, in the liquid mixture, the molar ratio of dimethyl sulfide to hydrogen peroxide is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

| Benzene adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com