Preparation method of canned yellow peach in syrup

A technology of canned yellow peaches and sugar water, which is applied in the direction of preserving fruits/vegetables with sugar, fresh-keeping of fruits and vegetables, and food preservation, etc. It can solve the problems of reducing the production efficiency of canned yellow peaches, destroying nutrients, and losing the flavor of yellow peaches, etc., and achieves hardness Moderate, bright golden color, no rough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

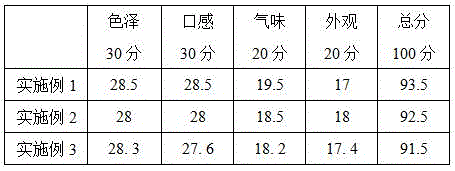

Examples

Embodiment 1

[0023] A preparation method of canned yellow peach in syrup, comprising the following steps:

[0024] 1) Select fresh yellow peaches with uniform size, bright color and plumpness, soak them in 1.5% sodium carbonate aqueous solution for 3 minutes, take them out, rinse the peach hairs with clean water, and immerse them in water. The weight ratio of yellow peaches to water is 1:1.8, add 5% mixed enzyme of yellow peach mass, mix evenly, soak at 42-45°C for 4 days, take it out, wash with water, and dry in the air; the mixed enzyme is neutral cellulase, hemicellulase, fruit Glue enzyme and amylase; The mass ratio of described neutral cellulase, hemicellulase, pectinase and amylase is 4:3:1.5:1;

[0025] 2) Immerse the yellow peaches treated in step 1) in water again, the weight ratio of yellow peaches to water is 1:1.2, add alkaline protease with 2.8% of the mass of yellow peaches, heat up to 52°C for 9 hours, and continue to heat up to 102°C Keep warm for 6 minutes, then cool down...

Embodiment 2

[0030] A preparation method of canned yellow peach in syrup, comprising the following steps:

[0031] 1) Select fresh yellow peaches with uniform size, bright color and plumpness, soak them in 1.5% sodium carbonate aqueous solution for 3 minutes, take them out, rinse the peach hairs with clean water, and immerse them in water. The weight ratio of yellow peaches to water is 1:1.5, add 4% yellow peach mixed enzyme, mix evenly, soak at 38-42°C for 3 days, take it out, wash with water, and dry in the air; the mixed enzyme is neutral cellulase, hemicellulase, fruit Glue enzyme and amylase; The mass ratio of described neutral cellulase, hemicellulase, pectinase and amylase is 4:3:1.5:1;

[0032] 2) Immerse the yellow peach treated in step 1) in water again, the weight ratio of yellow peach to water is 1:1.5, add alkaline protease with 2.5% of the mass of yellow peach, heat up to 50°C and keep it for 8 hours, then continue to heat up to 100°C Keep warm for 5 minutes, then lower the ...

Embodiment 3

[0037] A preparation method of canned yellow peach in syrup, comprising the following steps:

[0038] 1) Select fresh yellow peaches with uniform size, bright color and plumpness, soak them in 1.5% sodium carbonate aqueous solution for 3 minutes, take them out, rinse the peach hairs with clean water, and immerse them in water. The weight ratio of yellow peaches to water is 1:2, add 6% mixed enzyme of yellow peach mass, mix evenly, soak for 5 days at 42-46°C, take it out, wash with water, and dry in the air; the mixed enzyme is neutral cellulase, hemicellulase, fruit Glue enzyme and amylase; The mass ratio of described neutral cellulase, hemicellulase, pectinase and amylase is 4:3:1.5:1;

[0039] 2) Immerse the yellow peach treated in step 1) again in water, the weight ratio of yellow peach to water is 1:1.5, add alkaline protease with 3% of the mass of yellow peach, heat up to 55°C and keep it for 10h, then continue to heat up to 105°C Keep warm for 8 minutes, then cool down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com