Method for separating and preparing zirconia from zirconium oxychloride mother liquor

A technology of zirconium oxychloride mother and zirconia, which is applied in the field of separation and preparation of zirconia, which can solve the problems of thiocyanate toxicity, potential safety hazards, eye and skin irritation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

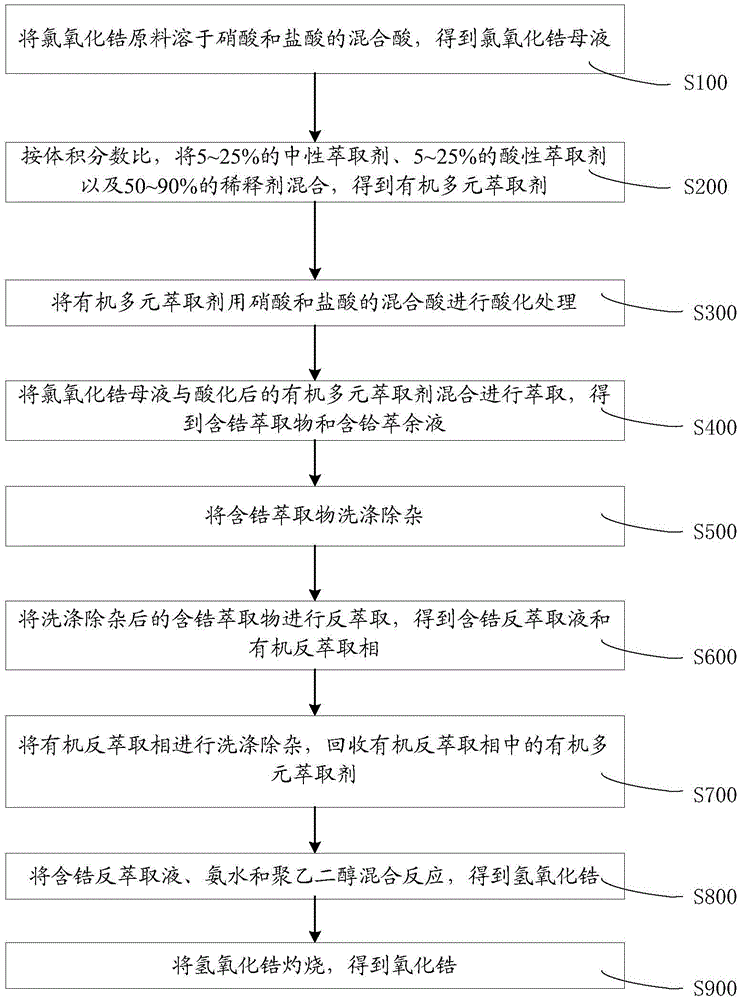

Method used

Image

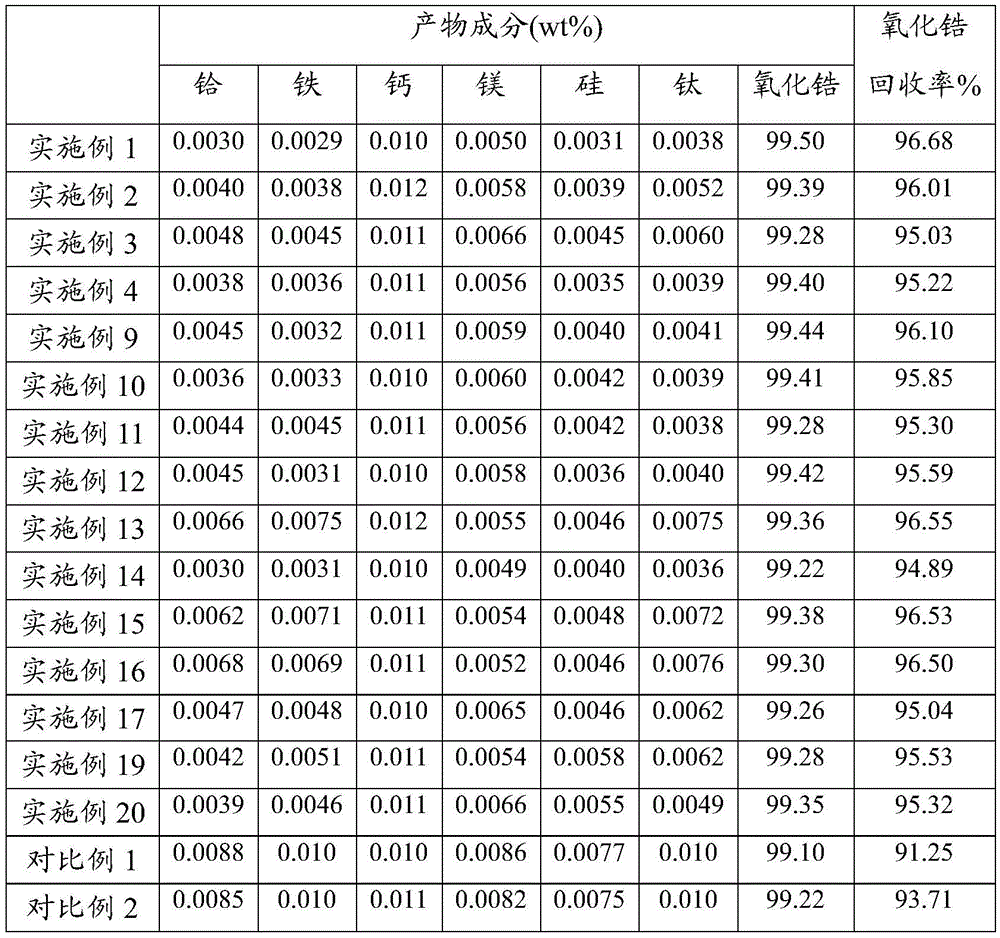

Examples

Embodiment 1

[0071] (1) Preparation of zirconium oxychloride mother liquor: dissolve 3.53Kg of zirconium oxychloride in 10L of mixed acid of nitric acid and hydrochloric acid (wherein the molar ratio of nitrate ion to chloride ion is 1.5:1), prepare 10L of chlorine Zirconia mother liquor. The obtained zirconium oxychloride mother liquor contains the zirconium of 100g / L, the hafnium of 3.53g / L, the iron of 0.18g / L, the calcium of 0.20g / L, the magnesium of 0.10g / L, the silicon of 0.16g / L and 0.36 g / L of titanium. The hydrogen ion concentration in the zirconium oxychloride mother liquor is 5mol / L.

[0072] (2) Preparation of organic multi-component extractant: 20% TOPO, 10% Cynex272 and 70% sulfonated kerosene were uniformly mixed according to the volume ratio to prepare 20L organic multi-component extractant.

[0073] (3) Acidification: Add 10L of mixed acid of nitric acid and hydrochloric acid with a hydrogen ion concentration of 5mol / L (wherein the molar ratio of nitrate ion to chloride ...

Embodiment 2

[0081] The difference between Example 2 and Example 1 lies in the composition of the organic multi-component extractant. By volume fraction ratio, 20% DBBP, 10% Cynex272 and 70% sulfonated kerosene are mixed uniformly to prepare 20L organic multi-component extractant .

Embodiment 3

[0083] The difference between Example 3 and Example 1 lies in the composition of the organic multi-component extractant. According to the volume fraction ratio, 20% of TBP, 10% of Cynex272 and 70% of sulfonated kerosene are mixed uniformly to prepare 20L organic multi-component extractant .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com