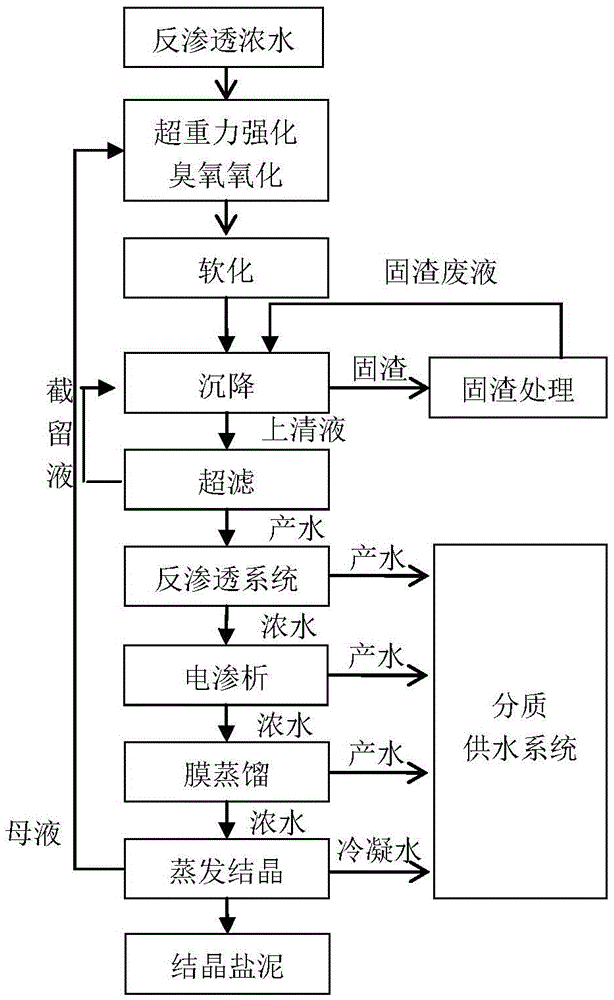

Integrated treatment process for reverse osmosis concentrated water in reuse of reclaimed water through near-zero discharge membrane method

A reverse osmosis concentrated water, near-zero discharge technology, applied in water/sewage treatment, heating water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of low reverse osmosis recovery rate and difficult treatment of reverse osmosis concentrated water , to save costs, reduce water evaporation, and reduce waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Recycled reverse osmosis concentrated water in papermaking enterprises, with a TDS of 1500 mg / L and a COD of 60 mg / L, is treated by the technical process of the invention. The reverse osmosis concentrated water is first adjusted to a pH of 8.5 with ammonia water, and the supergravity enhanced ozone oxidation is carried out. The supergravity factor is 20, and the ozone concentration is controlled at 5mg / L. The catalyst is ferrous sulfate, and the amount of catalyst added is 0.01% of the total mass of the reaction system. The reaction residence time was 15 minutes. After the reaction, the TDS of the reaction water is 1680mg / L, the COD is 20mg / L, and then enters the softening unit, adding Na 2 CO 3Carry out reaction softening, control hardness 5mg / L. The softened mixed liquid is settled by gravity, the supernatant enters the ultrafiltration unit, the sediment enters the solid residue treatment, and the separated solid residue waste liquid returns to the precipitation uni...

Embodiment 2

[0029] Recycled reverse osmosis concentrated water in a chemical enterprise has a TDS of 5000 mg / L and a COD of 1000 mg / L, which is treated by the technical process of the present invention. The reverse osmosis concentrated water is first adjusted to pH 13 with KOH, then supergravity enhanced ozone oxidation is carried out, the supergravity factor is 300, the ozone concentration is controlled at 160mg / L, the catalyst is manganese dioxide, and the amount of catalyst added is 1% of the total mass of the reaction system. The reaction residence time was 200 minutes. After the reaction, the TDS of the reaction water is 5000mg / L, the COD is 500mg / L, and then enters the softening unit, adding K 2 CO 3 Reactive softening was carried out to control the hardness to 300mg / L. The softened mixed liquid is settled by gravity, the supernatant enters the ultrafiltration unit, the sediment enters the solid residue treatment, and the separated solid residue waste liquid returns to the precipi...

Embodiment 3

[0031] Recycled reverse osmosis concentrated water in a dyestuff enterprise has a TDS of 2800 mg / L and a COD of 650 mg / L, which is treated by the technical process of the present invention. The reverse osmosis concentrated water is first adjusted to pH 11 with NaOH, and the reverse osmosis concentrated water is subjected to supergravity enhanced ozone oxidation. The supergravity factor is 130, and the ozone concentration is controlled at 15mg / L. The catalyst is nickel sulfate, and the amount of the catalyst added is the total mass of the reaction system. 0.05%, the reaction residence time is 300 minutes. After the reaction, the TDS of the reaction water is 3180mg / L, the COD is 342mg / L, and then enters the softening unit, adding Na 2 CO 3 Reaction softening is carried out, and the hardness is controlled to 100mg / L. The softened mixed liquid is settled by gravity, the supernatant enters the ultrafiltration unit, the sediment enters the solid residue treatment, and the separate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com