A method for improving high temperature oxidation resistance of titanium-based alloys

A technology for high-temperature oxidation resistance and titanium-based alloys, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of reducing the bonding strength of the coating and the substrate, expensive equipment, low production efficiency, etc., to improve the high-temperature oxidation resistance and excellent bonding force. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

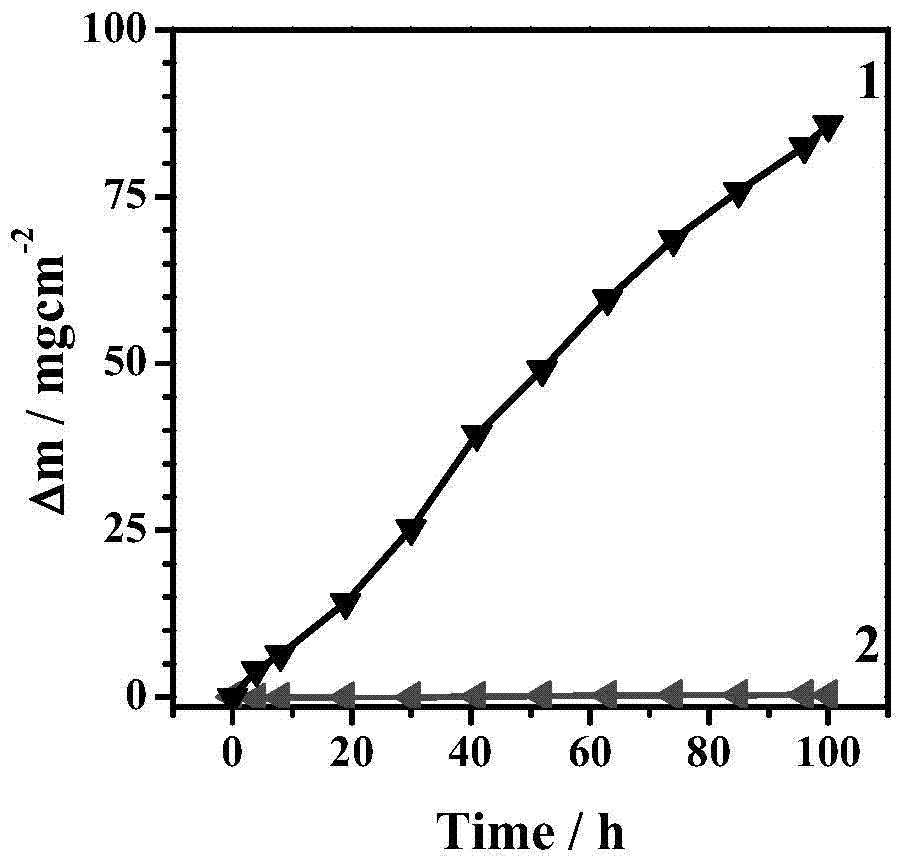

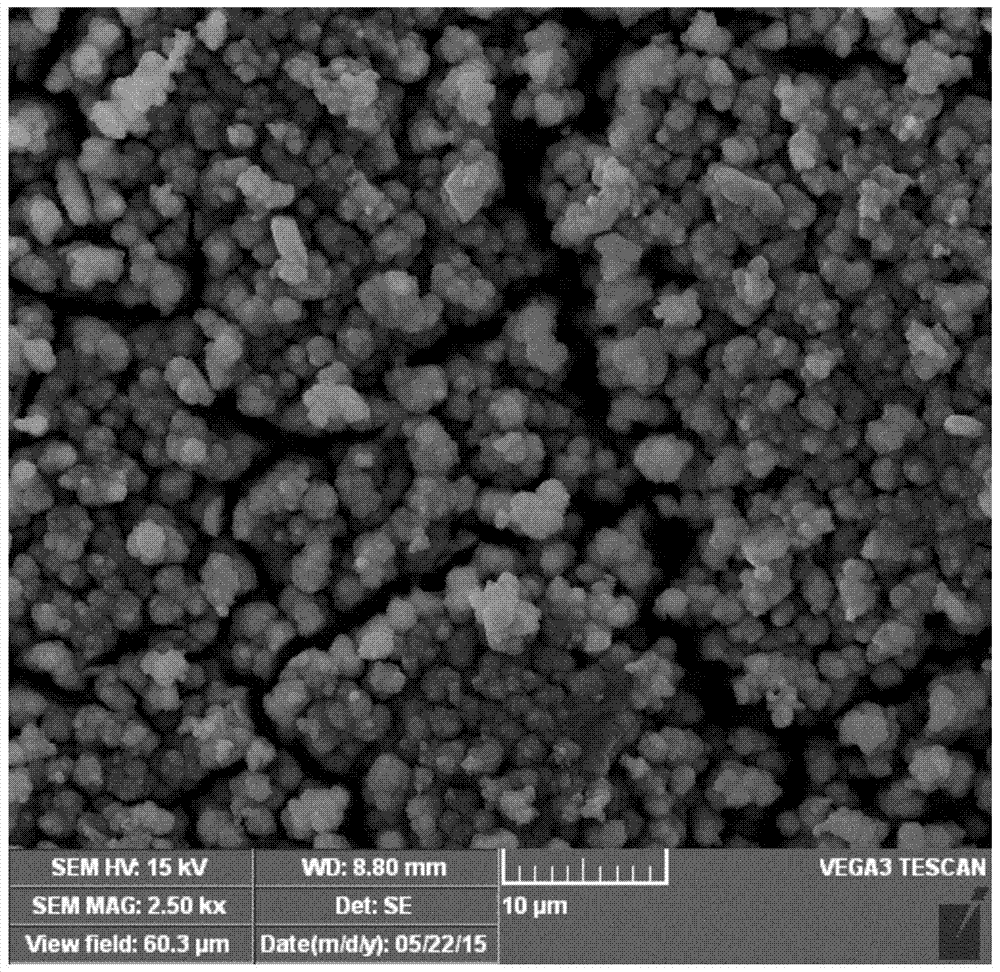

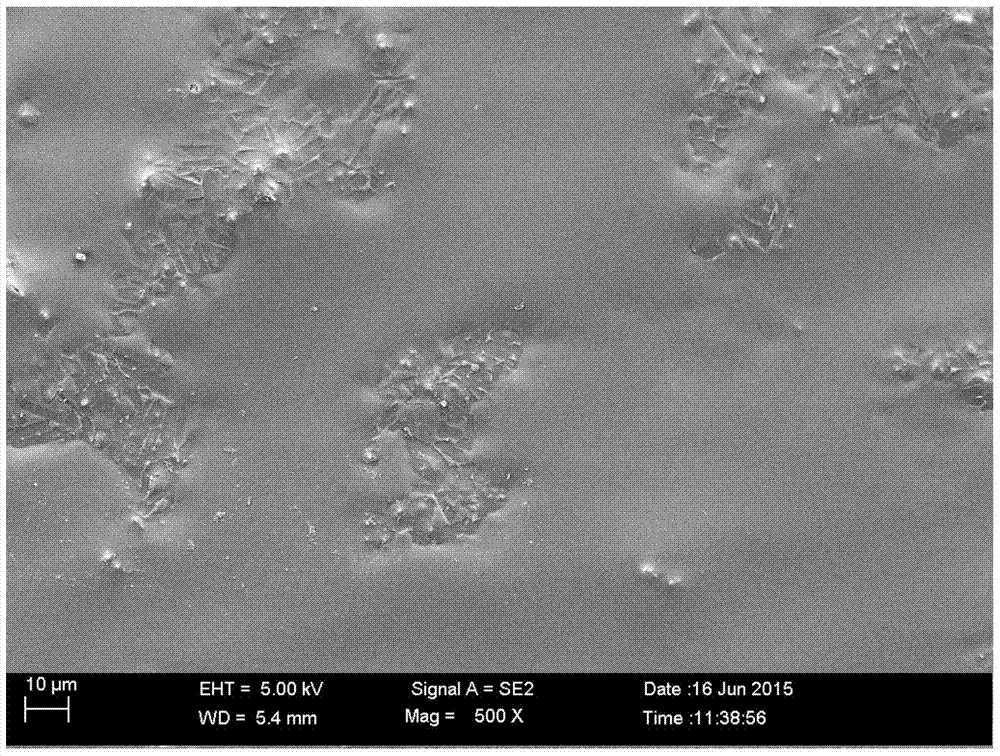

[0030] First, the titanium-aluminum alloy sample (titanium-aluminum atomic ratio is 1:1) was polished to remove surface oxides with sandpaper, then ultrasonically cleaned in acetone and ethanol for 10 min, and finally dried with hot air for use. At 40keV energy, inject 1×10 15 cm -2 Cl, the implanted sample was annealed in vacuum at 200°C for 4h. Add 50 mL of absolute ethanol, 50 mL of water, and 1 mL of tetraethyl orthosilicate (TEOS) to the beaker in sequence, and use 0.5 mol·L -1 Adjust the pH to about 2.0 with HCl, and stir at room temperature for 2 h to obtain a precursor solution for use. The former body solution is used as the electrolyte, the ion-implanted titanium-based alloy is used as the cathode, and the graphite electrode is used as the counter electrode. The electrode spacing is controlled at 1cm, and the current density is controlled at -0.1mA·cm -2 , the deposition time is 1000s, after the deposition is completed, the working electrode is rinsed with deioniz...

Embodiment 2

[0035] First, the titanium-aluminum alloy sample (titanium-aluminum atomic ratio is 1:1) was polished to remove surface oxides with sandpaper, then ultrasonically cleaned in acetone and ethanol for 10 min, and finally dried with hot air for use. At 80keV energy, inject 1×10 20 cm -2 Cl, the implanted sample was annealed in vacuum at 400°C for 0.5h. Add 100mL absolute ethanol, 100mL water, 10mL tetraethyl orthosilicate (TEOS) to the beaker in turn, 1.0mol·L - 1 HNO 3 Adjust the pH to about 6.0, and stir at room temperature for 6 hours to obtain a precursor solution for use. The former body solution is used as the electrolyte, the ion-implanted titanium-based alloy is used as the cathode, and the graphite electrode is used as the counter electrode. The electrode spacing is controlled at 10cm, and the current density is controlled at -0.1mA·cm -2, the deposition time is 1000s, after the deposition is completed, the working electrode is rinsed with deionized water and then dr...

Embodiment 3

[0039] First, the titanium-aluminum alloy sample (titanium-aluminum atomic ratio is 1:1) was polished to remove surface oxides with sandpaper, then ultrasonically cleaned in acetone and ethanol for 10 min, and finally dried with hot air for use. At 60keV energy, inject 1×10 16 cm -2 Cl, the implanted sample was annealed in vacuum at 300°C for 2h. Add 75mL of absolute ethanol, 100mL of water, and 5mL of methyl orthosilicate (TMOS) to the beaker in sequence, and use 2.0mol·L -1 Adjust the pH to about 3.0 with HAc, and stir at room temperature for 4 h to obtain a precursor solution for use. The former body solution is used as the electrolyte, the ion-implanted titanium-based alloy is used as the cathode, and the graphite electrode is used as the counter electrode. The electrode spacing is controlled at 5 cm, and the current density is controlled at -2.0 mA cm -2 , the deposition time is 300s. After the deposition is completed, the working electrode is rinsed with deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com