Combination of cylinder bore and piston ring

A technology of piston rings and cylinder holes, applied in the directions of piston rings, cylinders, cylinder heads, etc., can solve a large number of precision processes, impracticality and other problems, and achieve the effects of excellent wear resistance, small area ratio and small friction loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~2

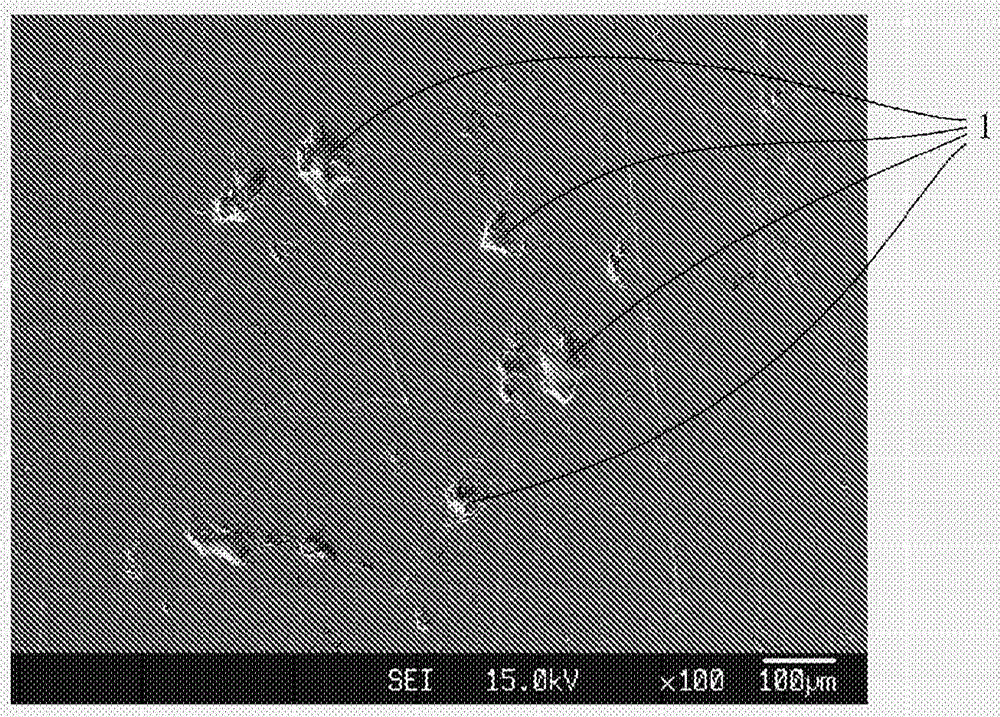

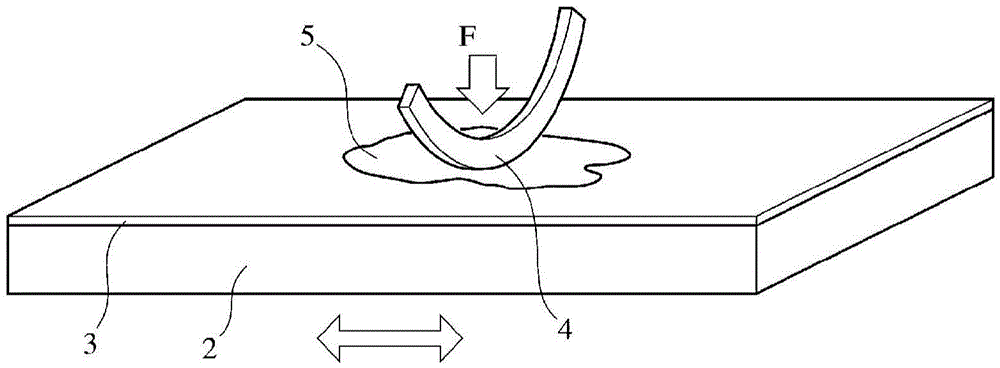

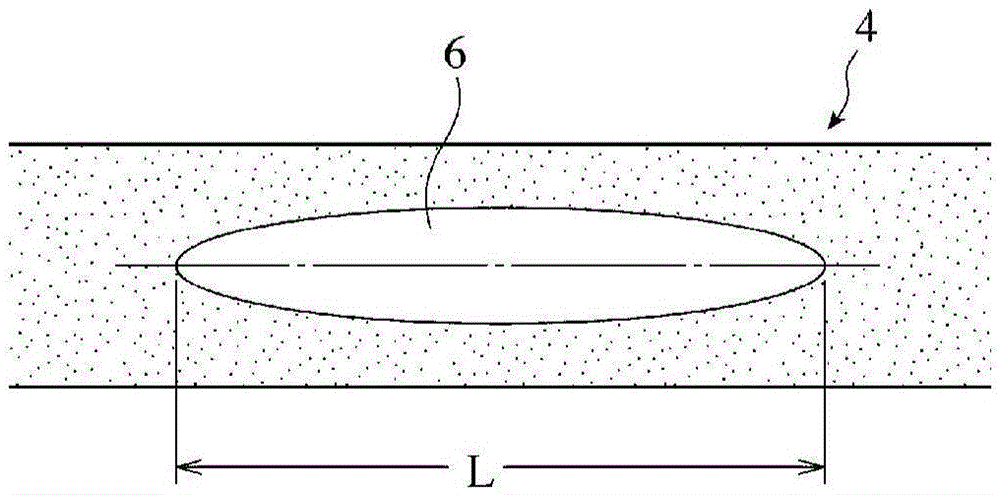

[0031] Sand blasting is performed on one side of a JISADC12 aluminum alloy plate (70mm×100mm×10mm) equivalent to the cylinder bore, and the mass % is C: 0.3%, Si: 0.2%, Mn: 0.3%, Cr: 0.5%, A wire composed of Mo: 0.2%, the rest of Fe and unavoidable impurities is used as a thermal spraying material, and an iron-based thermal spraying film of about 500 μm is formed by an arc thermal spraying method. The iron-based thermal sprayed coatings of Examples 1 to 4 and Comparative Examples 1 to 2 were basically formed under the same thermal spraying conditions, but were polished in the 70 mm width direction so that the surface properties (Rpk value) were different. Next, the piston ring (equivalent to SUS420J2 subjected to nitriding treatment, nominal diameter (d) 90 mm, width (h1) 1.2 mm, thickness (a1) 3.2 mm) forms a hard carbon film of about 1 μm on the outer peripheral surface. Since the hard carbon films of Examples 1 to 4 and Comparative Examples 1 to 2 had Rpk of 0.2 to 0.3 μm ...

Embodiment 5~7

[0049] Aluminum alloy plates corresponding to the cylinder bores of Examples 5 to 7 were produced in the same manner as in Example 1 except that the thermal spraying conditions of the iron-based thermal sprayed coating were changed so as to vary the area ratio of the minute pits. In addition, a hard carbon film having the same properties as in Example 1 was used for a piston ring combined with these aluminum alloy plates. The Rpk value and micro-crater area ratio of the iron-based thermal sprayed coatings of Examples 5-7 were measured similarly to Example 1, and the abrasion test and abrasion test were also performed similarly to Example 1.

Embodiment 8

[0051] The material of the piston ring is SUS440B equivalent material, and a CrN film base layer with a film thickness of about 30 μm is formed on it, and a metal Cr intermediate layer of about 0.5 μm and a hard carbon film of about 1.5 μm are formed by vacuum arc ion plating. Other than that, the piston ring of Example 8 was produced in the same manner as in Example 1. As a result of measuring the Rpk value, hydrogen content, and Martens hardness of the hard carbon film, the Rpk value was 0.14 μm, the hydrogen content was 0.7 atomic %, and the Martens hardness was 24.1 GPa. In addition, as an aluminum alloy plate combined with the piston ring of Example 8, an iron-based thermal sprayed coating having the same properties as in Example 1 was used, and an abrasion test and an abrasion test were performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com