Fluorine-doped fluorescent carbon quantum dot preparing method

A technology of carbon quantum dots and fluorine doping, applied in chemical instruments and methods, nano optics, luminescent materials, etc., can solve the problems of high energy consumption, complicated preparation process, low yield, etc., and achieve good photostability, good The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] (1) Add 40mL of 7mmol / L glucose dispersion into the polytetrafluoroethylene hydrothermal reaction kettle, the solvent of the dispersion is ethanol, then add 1mL of hydrofluoric acid, cover and seal.

[0025] (2) Put the reaction kettle in (1) into a muffle furnace, and react at 200° C. for 24 hours.

[0026] (3) The solution obtained in (2) is passed through a filter membrane with a pore size of 0.22 μm to remove large particles, and the obtained filtrate is added to a dialysis bag for dialysis (molecular weight cut-off is 500D), the dialysis fluid is deionized water, and the dialysis time is 2 - 7 days, change the deionized water every 6 hours.

[0027] (4) Transfer the product in the dialysis bag to a flask, and remove the solvent by distillation under reduced pressure.

[0028] (5) Dry the solid obtained in (4) in a vacuum drying oven for 48 hours to obtain a fluorine-doped fluorescent carbon quantum dot product. The product mass obtained was 19.8 mg.

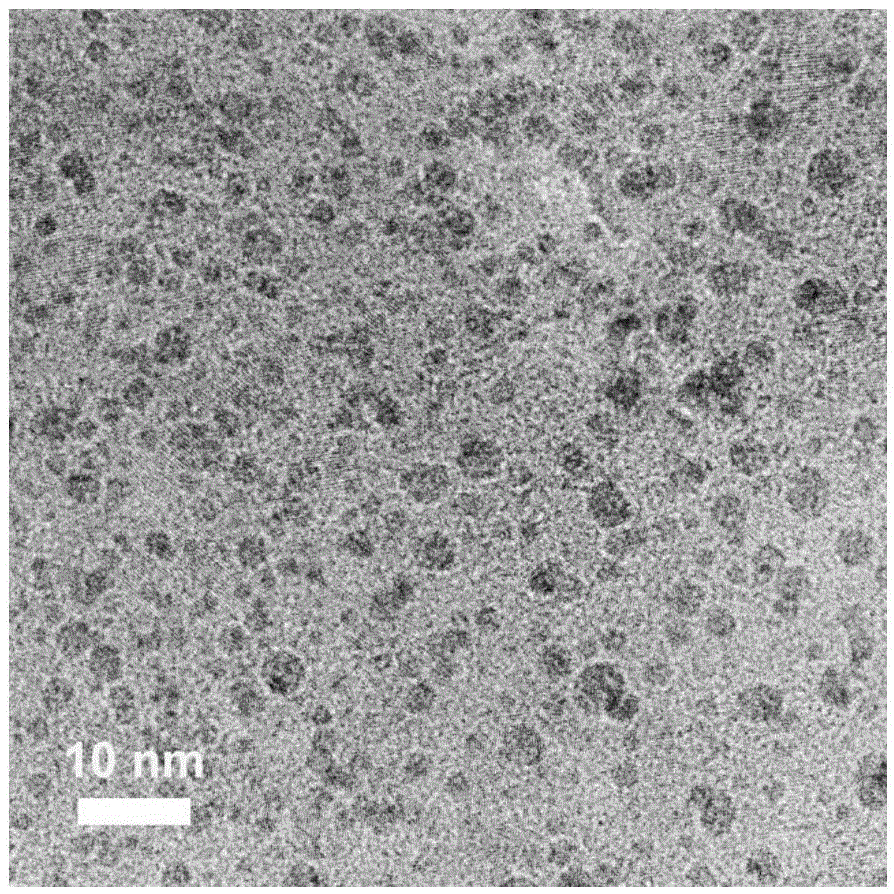

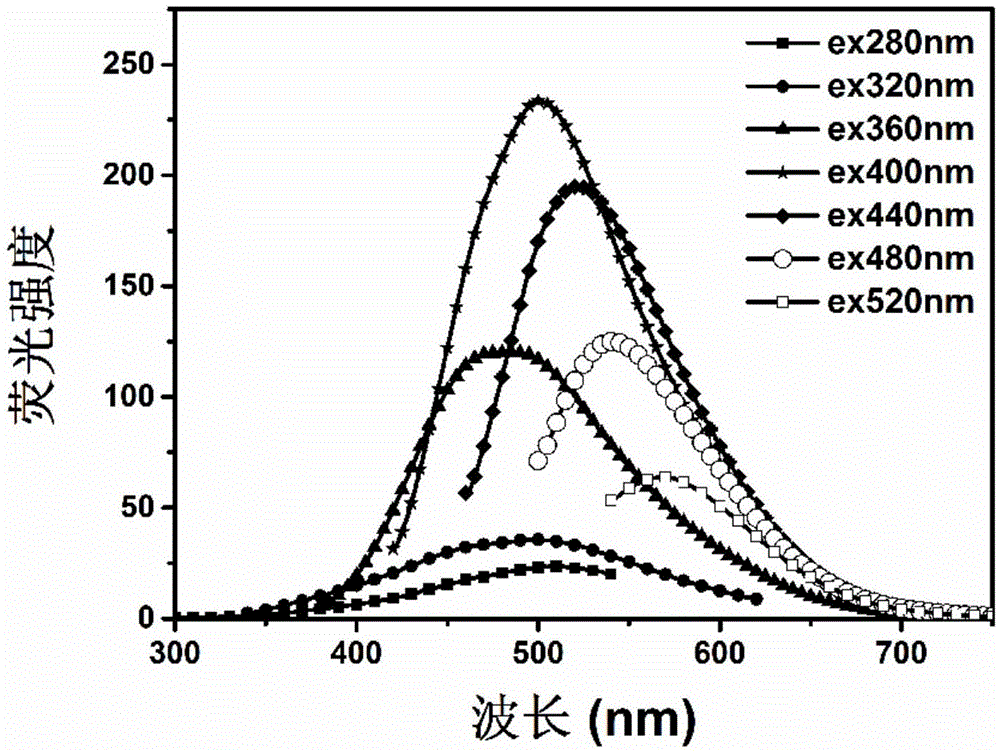

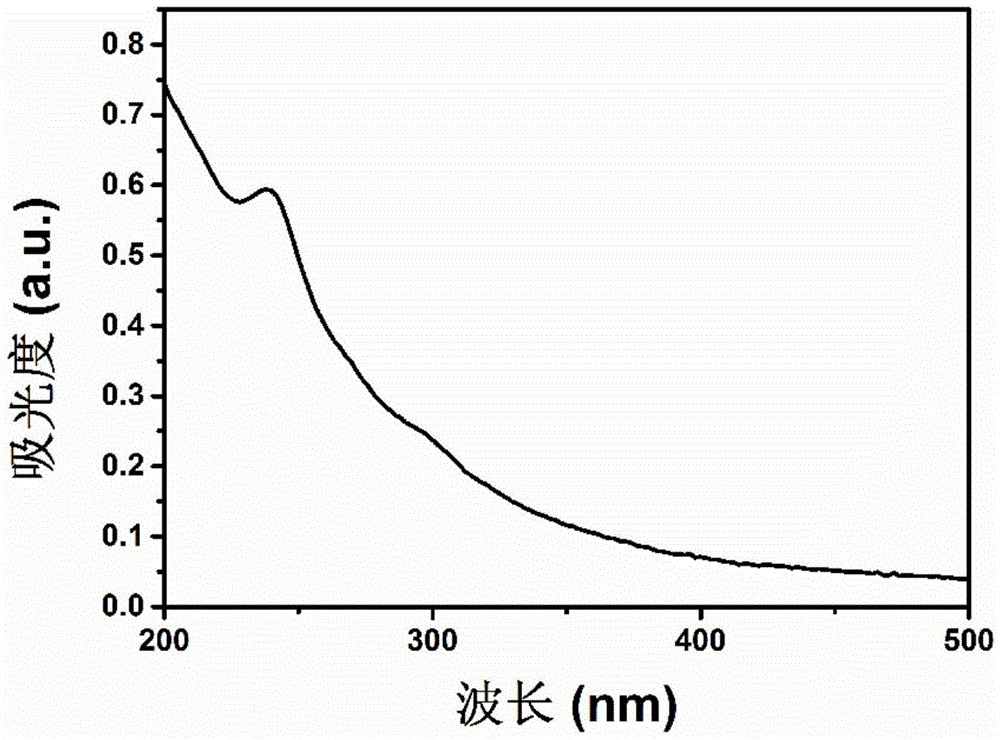

[0029] The...

example 2

[0034] (1) Add 40mL of 28mmol / L glucose dispersion into a polytetrafluoroethylene hydrothermal reaction kettle, the dispersion solvent is acetonitrile, then add 2mL of hydrofluoric acid, cover and seal.

[0035] (2) Put the reaction kettle in (1) into a muffle furnace, and react at 180° C. for 24 hours.

[0036] (3) The solution obtained in (2) is passed through a filter membrane with a pore size of 0.22 μm to remove large particles, and the obtained filtrate is added to a dialysis bag for dialysis (molecular weight cut-off is 500D), the dialysis fluid is deionized water, and the dialysis time is 2 - 7 days, change the deionized water every 6 hours.

[0037] (4) Transfer the product in the dialysis bag to a flask, and remove the solvent by distillation under reduced pressure.

[0038] (5) Dry the solid obtained in (4) in a vacuum drying oven for 48 hours to obtain a fluorine-doped fluorescent carbon quantum dot product. The product mass obtained was 46.8 mg.

example 3

[0040] (1) Add 40mL of 14mmol / L glucose dispersion into the polytetrafluoroethylene hydrothermal reaction kettle, the solvent of the dispersion is ethanol, then add 1mL of hydrofluoric acid, cover and seal.

[0041] (2) Put the reaction kettle in (1) into a muffle furnace, and react at 160° C. for 24 hours.

[0042] (3) The solution obtained in (2) is removed large particles through a filter membrane with a pore size of 0.22 μm, and the obtained filtrate is added to a dialysis bag for dialysis (molecular weight cut-off is 500D), and the dialysis fluid is deionized water, and the dialysis time is 2 - 7 days, change the deionized water every 6 hours.

[0043] (4) Transfer the product in the dialysis bag to a flask, and remove the solvent by distillation under reduced pressure.

[0044] (5) Dry the solid obtained in (4) in a vacuum drying oven for 48 hours to obtain a fluorine-doped fluorescent carbon quantum dot product. The product mass obtained was 22.2 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com