Magnesium-containing multiphase porous bioceramic

A bioceramic and porous stent technology, applied in the field of medical materials, can solve the problems of not having good three-dimensional interconnected mesh structure, degradability and biological activity, and achieve the effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

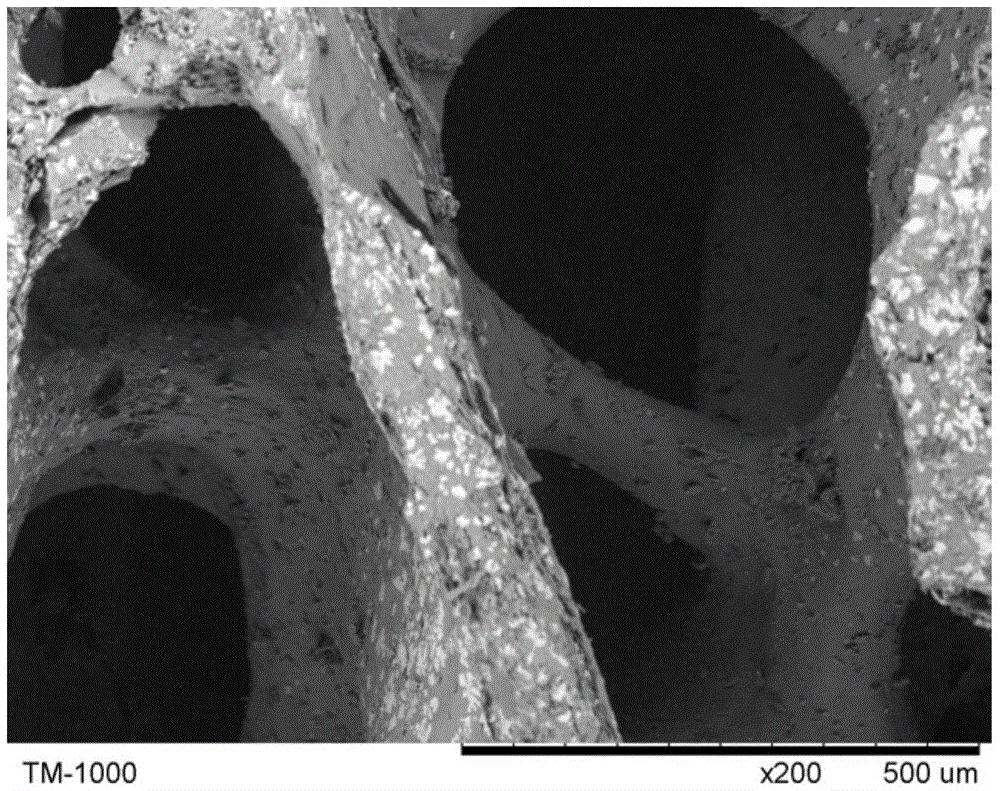

[0036] (1) cutting bovine femoral condyle cancellous bone into bone strips with a thickness of 0.5-1.0 cm to obtain raw bone;

[0037] (2) Put the raw bone in distilled water and cook it in a pressure cooker (the water temperature can reach up to 116°C±1°C) for 35 minutes, then wash it with 60°C water, repeat this step 6 times;

[0038] (3) Dry the raw bone treated in step (2) in a constant temperature oven at 90°C for 48 hours, then place it in a calcination furnace, and calcinate it at 1100°C (heating rate 10°C / min) for 10 hours, and then cool it with the furnace to obtain beef bone. Calcined cancellous bone mineral porous scaffold.

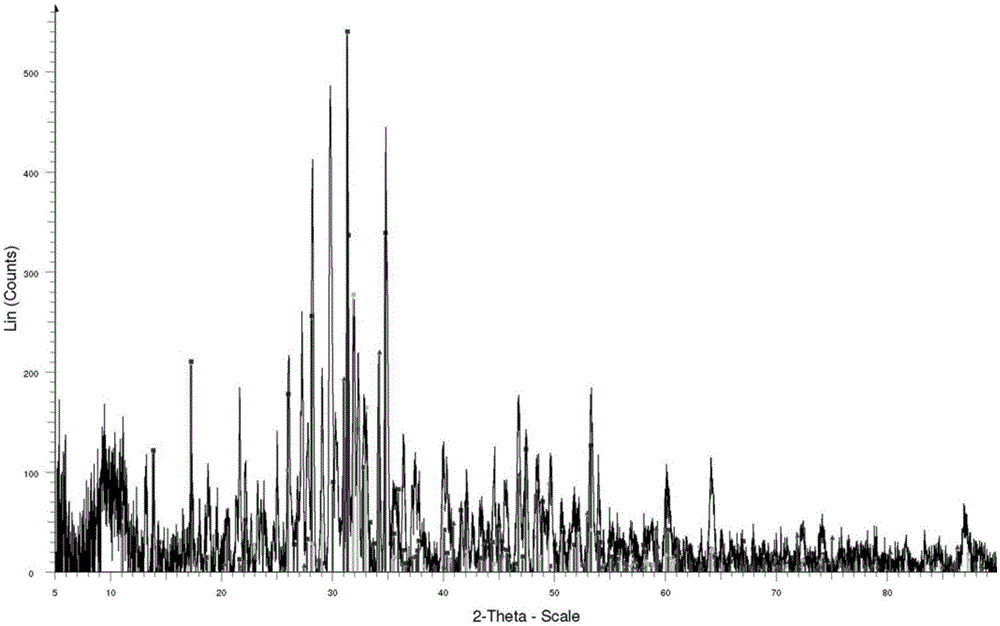

[0039] The results of X-ray powder diffraction analysis of bovine calcined cancellous bone ore were hydroxyapatite.

preparation example 2

[0041] (1) cutting bovine cancellous bone (bovine femoral condyle cancellous bone) into bone strips and bone blocks with a thickness of 0.5-1 cm to obtain raw bone;

[0042] (2) The raw bone is placed in distilled water and boiled in a pressure cooker for 50 minutes, then washed with pH water, and this step is repeated 5 times;

[0043] (3) Dry the raw bone treated in step (2) in a constant temperature oven at 100°C for 24 hours, then place it in a calciner, and calcinate it at 1000°C (heating rate 10°C / min) for 12 hours, and then cool it with the furnace to obtain beef bone. Calcined cancellous bone mineral porous scaffold.

[0044] The results of X-ray powder diffraction analysis of bovine calcined cancellous bone ore were hydroxyapatite.

preparation example 3

[0046] (1) cutting bovine femoral condyle cancellous bone into bone blocks with a thickness of 1-2 cm to obtain raw bone;

[0047] (2) Put the raw bone in distilled water and cook it in a pressure cooker for 60 minutes, then wash it with water at 60°C, and repeat this step 5 times;

[0048] (3) Dry the raw bone treated in step (2) in a constant temperature oven at 120°C for 12 hours, then place it in a calciner, calcinate it at 1200°C (heating rate 10°C / min) for 8 hours, and cool it with the furnace to obtain a cow Calcined cancellous bone mineral porous scaffold.

[0049] The results of X-ray powder diffraction analysis of bovine calcined cancellous bone ore were hydroxyapatite.

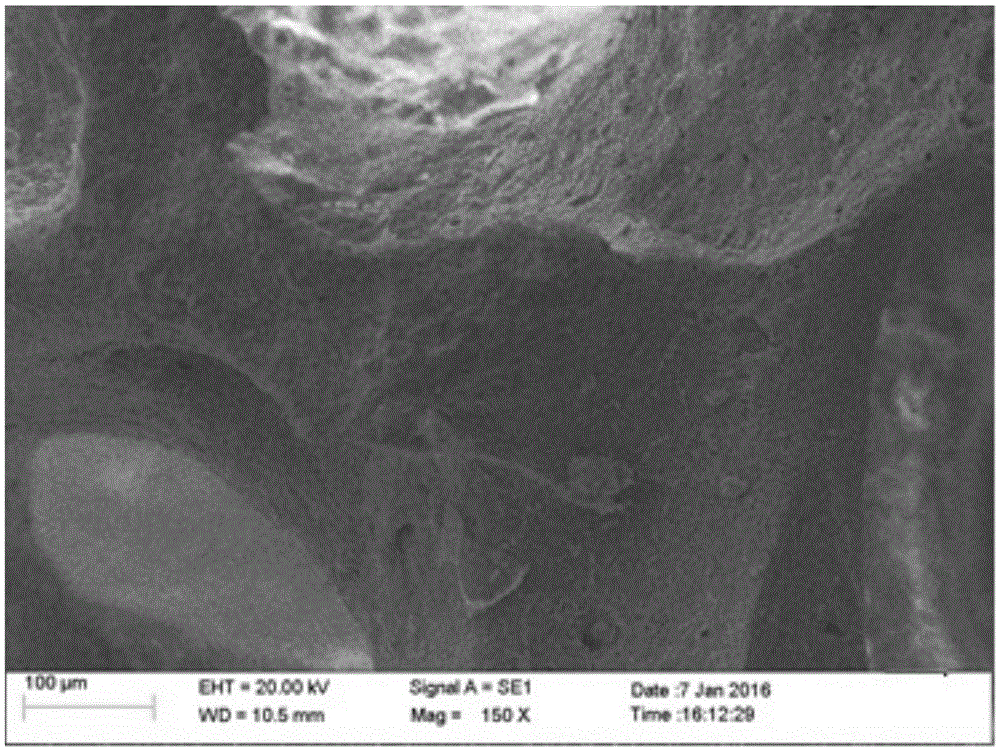

[0050] Embodiment overall scheme 1:

[0051] A: Immerse the bovine calcined cancellous bone ore porous scaffold in the magnesium source-phosphorus source composite solution (the solid-liquid ratio of the bovine calcined cancellous bone ore porous scaffold to the magnesium source-phosphorus source ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com