Industrial circulating water synergist

A technology of industrial circulating water and synergist, which is applied in the directions of descaling and water softening, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. Index out of control, shorten the service life of equipment, etc., to prevent corrosive ions from contacting equipment, enhance corrosion resistance, and protect against corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: An industrial circulating water synergist, comprising the following components in weight percentage: fatty alcohol polyoxyethylene ether 5%, acrylic acid 10%, polyepoxysuccinic acid 20%, hydroxyethylidene diphosphonic acid 22% , disodium edetate 6.0%, dodecyl dimethyl benzyl ammonium bromide 2%, the balance is water. After the above-mentioned components are mixed uniformly in sequence according to the proportion, the pH can be adjusted to be neutral with sodium hydroxide.

Embodiment 2

[0024] Embodiment 2: An industrial circulating water synergist, comprising the following components in weight percentage: fatty alcohol polyoxyethylene ether 7.0%, acrylic acid 11%, polyepoxysuccinic acid 19%, hydroxyethylidene diphosphonic acid 24% , disodium edetate 6.5%, dodecyl dimethyl benzyl ammonium bromide 3%, the balance is water. After the above-mentioned components are mixed uniformly in sequence according to the proportion, the pH can be adjusted to be neutral with sodium hydroxide.

Embodiment 3

[0025] Example 3 This example is an energy-saving and efficiency-enhancing project implemented on the circulating water system of Xinhua Pharmaceutical Co., Ltd. by using the industrial circulating water synergist of the present invention.

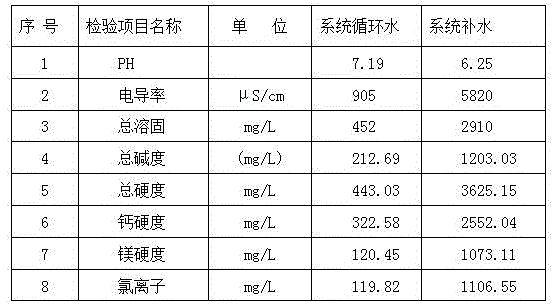

[0026] The company's circulating water system has a water volume of 1000m3, a circulation volume of 1600m3 / h, a sewage discharge volume of 60m3 / h, and a water replenishment volume of 100m3 / h. The water replenishment is ground water, the pipe material is carbon steel, and the heat exchange equipment in the system is made of stainless steel, carbon steel, and copper. Tube. The system has been in operation for three years, and the equipment has corrosion and scaling problems, and the heat exchange effect of the equipment has dropped by about 20%. System water quality analysis is shown in Table 1.

[0027] Table 1 Water quality analysis of circulating water system of Xinhua Pharmaceutical Co., Ltd.

[0028]

[0029] Considering that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com