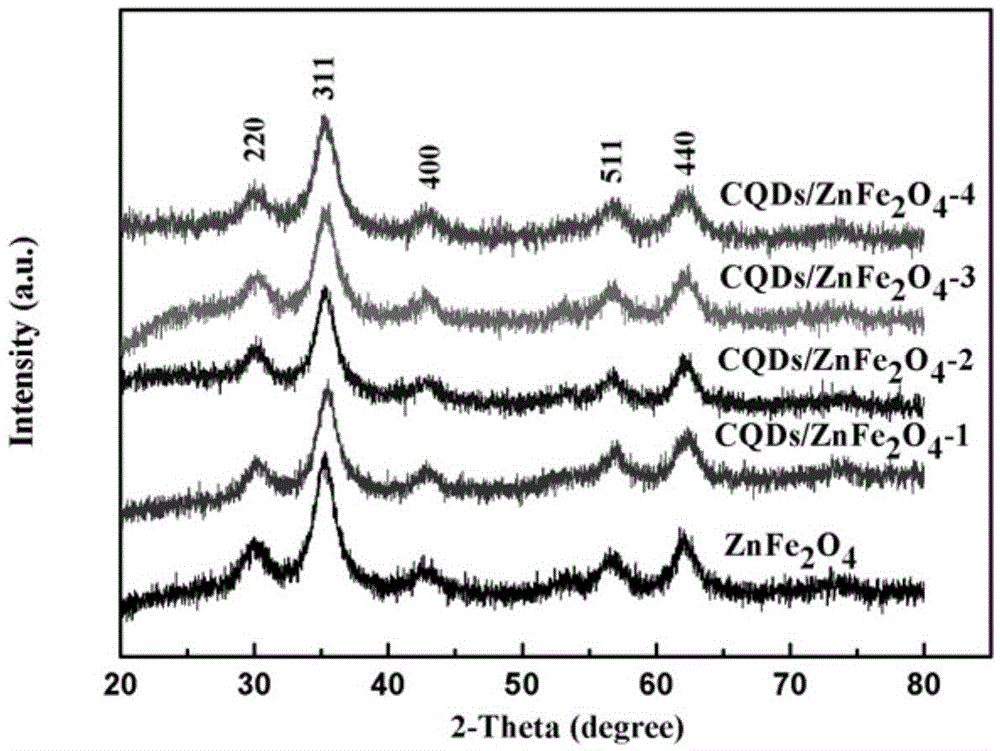

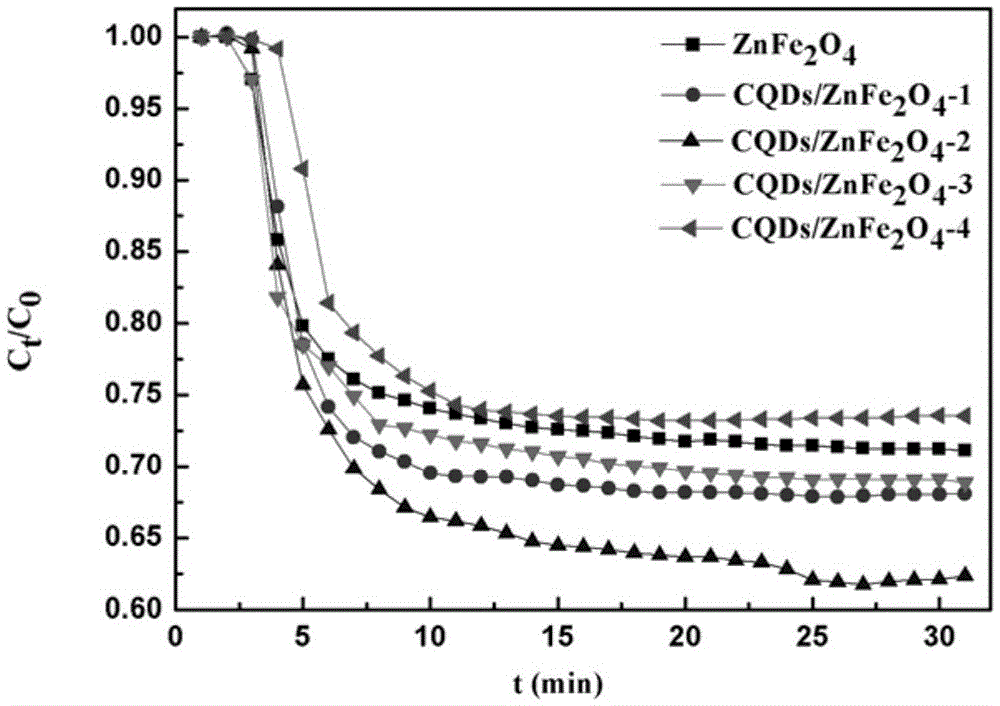

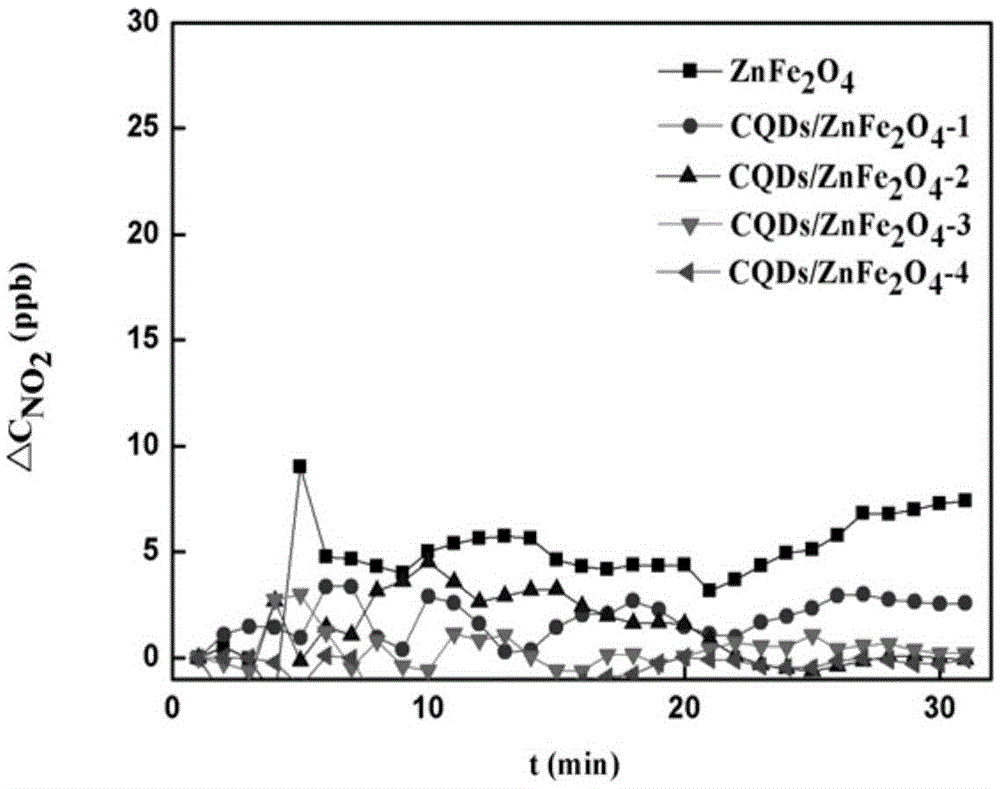

Preparation method of carbon quantum dot/zinc ferrite composite photocatalytic materials

A technology of composite photocatalysis and carbon quantum dots, applied in the field of photocatalysis, can solve the problems of high degradation rate and inability to degrade nitrogen oxides, etc., and achieve the effects of high degradation efficiency, cheap and easily available raw materials, and low synthesis cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a. Weigh 1.6g of ascorbic acid, add it to a mixed solution of 15mL ethylene glycol and 25mL deionized water, stir at room temperature for 30min, then react at 160°C for 70min to obtain an aqueous solution of carbon quantum dots;

[0029] b. Weigh 1.189g of Zn(NO 3 ) 2 ·6H2 O and 3.232g of Fe(NO 3 ) 3 9H 2 O, then add 20mL deionized water, stir until the solution is clear at room temperature;

[0030] c. adjust the pH value of the solution obtained in step b with a 2mol / L NaOH solution, so that the pH value reaches 13.0 to obtain a suspension;

[0031] d. Add 1 mL of the carbon quantum dot aqueous solution obtained in step a to the suspension obtained in the above step c;

[0032] e. After stirring evenly, let it stand for 1 day, then transfer it to a 100mL polytetrafluoroethylene liner, conduct a hydrothermal reaction at 100°C for 6 hours, wash it with deionized water and ethanol several times, and dry it at 70°C to obtain carbon quantum Dot / zinc ferrite composite...

Embodiment 2

[0034] a. Weigh 1.6g of ascorbic acid, add it to a mixed solution of 15mL ethylene glycol and 25mL deionized water, stir at room temperature for 30min, then react at 160°C for 70min to obtain an aqueous solution of carbon quantum dots;

[0035] b. Weigh 1.189g of Zn(NO 3 ) 2 ·6H 2 O and 3.232g of Fe(NO 3 ) 3 9H 2 O, then add 20mL deionized water, stir until the solution is clear at room temperature;

[0036] c. adjust the pH value of the solution obtained in step b with a 2mol / L NaOH solution, so that the pH value reaches 13.0 to obtain a suspension;

[0037] d. Add 3 mL of the carbon quantum dot aqueous solution obtained in step a to the suspension obtained in the above step c;

[0038] e. Stir for a period of time to mix evenly, then let it stand for 1 day, then transfer it to a 100mL polytetrafluoroethylene liner, conduct a hydrothermal reaction at 100°C for 6 hours, wash it with deionized water and ethanol for several times, and dry it at 70°C. A carbon quantum dot / ...

Embodiment 3

[0040] a. Weigh 1.6g of ascorbic acid, add it to a mixed solution of 15mL ethylene glycol and 25mL deionized water, stir at room temperature for 30min, then react at 160°C for 70min to obtain an aqueous solution of carbon quantum dots;

[0041] b. Weigh 1.189g of Zn(NO 3 ) 2 ·6H 2 O and 3.232g of Fe(NO 3 ) 3 9H 2 O, then add 20mL deionized water, stir until the solution is clear at room temperature;

[0042] c. adjust the pH value of the solution obtained in step b with a 2mol / L NaOH solution, so that the pH value reaches 13.0 to obtain a suspension;

[0043] d. Add 5 mL of step a obtained carbon quantum dot aqueous solution to the suspension obtained in the above step c;

[0044] e. Stir for a period of time to make the mixture even and let it stand for 1 day, then transfer it to a 100mL polytetrafluoroethylene liner, conduct a hydrothermal reaction at 100°C for 6 hours, wash it with deionized water and ethanol several times, and dry it at 70°C , to obtain carbon quant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com