Preparation method and application method of cellulose xanthogenate heavy metal capturing agent

A heavy metal scavenger and xanthate technology, applied in the fields of resources and environment, can solve the problems of low sulfonation product heavy metal scavenging effect, low cellulose sulfonation rate, increased raw material cost, etc. Economical cost is low, the effect of using less alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

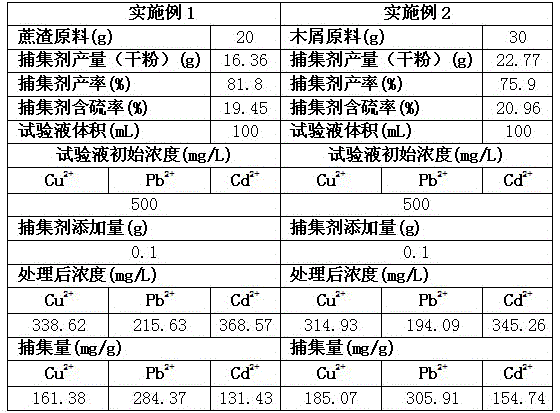

Embodiment 1

[0043] 1) Take the bagasse raw material, wash, dry, pulverize and grind, sieve 60 mesh, and set aside;

[0044] 2) Add 150mL of 20% sodium hydroxide solution pre-cooled to 0~4°C to a 500mL three-necked flask with a stirrer; add 20g of the above-mentioned bagasse dry powder sieved to 60 mesh; stir in an ice bath for 30 minutes; add 150mL A mixed solution containing 6% urea and 8% thiourea was stirred in an ice bath for 60 minutes;

[0045] 3) Add 6mL carbon disulfide solution, stir and react in an ice bath for 2 hours; put the three-neck flask still, pour out the supernatant;

[0046] The bagasse cellulose solution undergoes a sulfonation reaction consisting of the following general reaction formula in the presence of carbon disulfide and alkali to generate bagasse cellulose xanthate sodium salt:

[0047] 3CS 2 +6NaOH→2Na 2 CS 3 +Na 2 CO 3 +3H 2 o

[0048] (C 6 h 9 o 4 Oh) n +nNa 2 CS 3 →(C 6 h 9 o 4 OCSSNa) n ↓+nNaHS

[0049] NaHS+NaOH→Na 2 S+H 2 o

[005...

Embodiment 2

[0057] 1) Take sawdust raw material, wash, dry, pulverize and grind, sieve 60 meshes, set aside;

[0058] 2) Add 200mL of 16% sodium hydroxide solution pre-cooled to 0~4°C to a 500mL three-necked flask with a stirrer; add 30g of the above-mentioned dry powder of sawdust sieved to 60 mesh; stir in an ice bath for 60 minutes; add 200mL containing Mixed solution of 6% urea and 8% thiourea, stirred in ice bath for 60 minutes;

[0059] 3) Add 10mL of carbon disulfide solution, stir and react in ice bath for 2 hours; put the three-neck flask still, pour out the supernatant;

[0060] In the presence of carbon disulfide and alkali, the wood chip cellulose solution undergoes a sulfonation reaction consisting of the following general reaction formula to generate wood chip cellulose xanthate sodium salt:

[0061] 3CS 2 +6NaOH→2Na 2 CS 3 +Na 2 CO 3 +3H 2 o

[0062] (C 6 h 9 o 4 Oh) n +nNa 2 CS 3 →(C 6 h 9 o 4 OCSSNa) n ↓+nNaHS

[0063] NaHS+NaOH→Na 2 S+H 2 o

[0064]...

Embodiment 3

[0073] The cellulose xanthate heavy metal trapping agent made by Example 1 and Example 2 can be applied to heavy metal mining, waste water, heavy metal capture treatment, recovery, heavy metal-containing sludge, bottom mud and heavy metal-contaminated soil Heavy metal exchange, extraction recovery, etc.

[0074] The captured metals include, but are not limited to: copper, lead, zinc, cadmium, nickel, mercury, arsenic, antimony, chromium, manganese, gold, silver, platinum, thallium, uranium, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com