Method for separating phenol, arene and alkane in direct coal liquefaction effluent through one-step method

A technology for directly liquefying oil and aromatics from coal, applied in the field of coal chemical industry, can solve the problems of high separation cost, low product purity, and low separation efficiency, and achieve the effects of broad application prospects, high product purity, and low system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

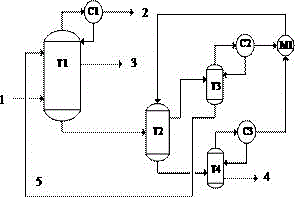

Image

Examples

Embodiment 1

[0030] In Example 1, the target products are phenolic compounds, aromatics and alkanes. Dimethyl sulfoxide is used as No. 1 solvent A for the narrow fraction to be separated at 150-180°C; sulfolane and dimethyl sulfone with a mass ratio of 1:1 are used as No. 2 solvent for the narrow fraction to be separated at 200-220°C a. The feeding method is continuous feeding.

[0031] The extractive distillation condition of 150-180 DEG C cut in the embodiment 1 of table 1

[0032] Process conditions

Extractive distillation column T1

Extraction tower T2

Number of plates

1

1

mass solvent ratio

1.0

-

Reflux ratio

0

-

Tower top temperature °C

190

25

Tower bottom temperature °C

225

25

Tower top pressure MPa

0.101

0.101

Tower bottom pressure MPa

0.121

0.111

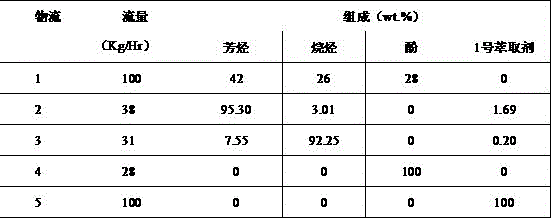

[0033] The extractive distillation result of 150-180 DEG C cut in the embodiment 1 of table 2

[0034]

Embodiment 2

[0035] The extractive distillation condition of 200-220 ℃ in the embodiment 2 of table 3

[0036] Process conditions

Extractive distillation column T1

Extraction tower T2

Number of plates

3

1

mass solvent ratio

1.0

-

Reflux ratio

1

-

Tower top temperature °C

220

25

Tower bottom temperature °C

260

25

Tower top pressure MPa

0.101

0.101

Tower bottom pressure MPa

0.130

0.111

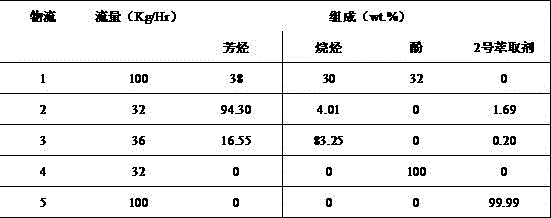

[0037] The extractive distillation result of 200-220 DEG C cut in the embodiment 2 of table 4

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com