Copper-selective etching solution and titanium-selective etching solution

An etching solution and selective technology, applied in the field of semiconductor element processing, can solve the problems of low etching selectivity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~3

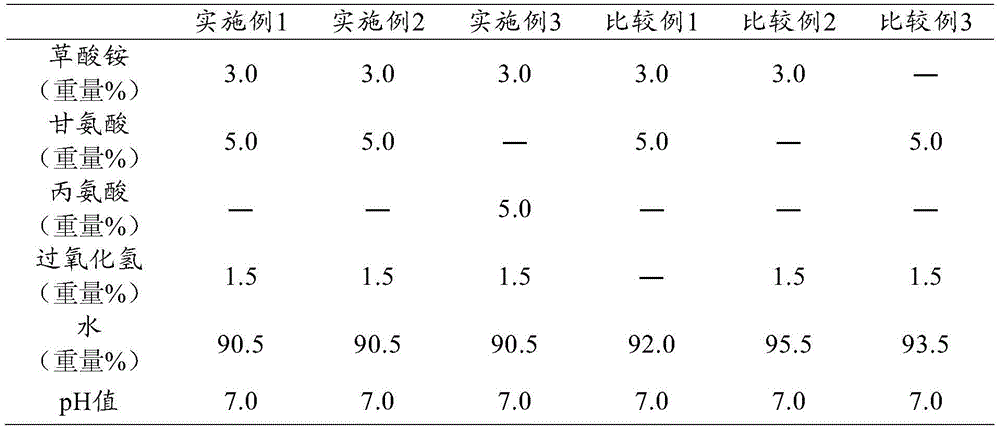

[0046] 1. The components and contents of Examples 1-3 and Comparative Examples 1-3 are shown in Table 1.

[0047] According to the components and proportions of Examples 1-3, the hydrogen peroxide is firstly diluted with water to obtain a copper oxidation solution, and then the remaining components and the remaining water are mixed to obtain a copper chelating solution. Finally, the copper oxide solution and the copper chelating solution are mixed to obtain a copper selective etching solution for etching. Then, according to the components and proportions of Comparative Examples 1-3, the copper contrast etching solution was prepared in the same way.

[0048] Among them, the pH value is adjusted by the copper etching solution pH regulator HCl, H 2 SO 4 , KOH and / or NaOH for adjustment.

[0049] The composition and content of table 1 copper selective etching solution, copper contrast etching solution

[0050]

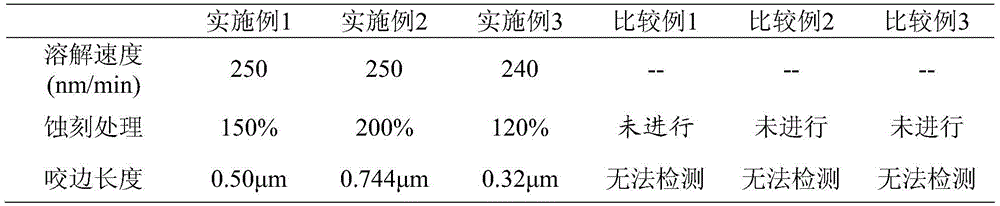

[0051] 2. Cu etching test

[0052] Etching speed test: place ...

Embodiment 4~8 and comparative example 4~7

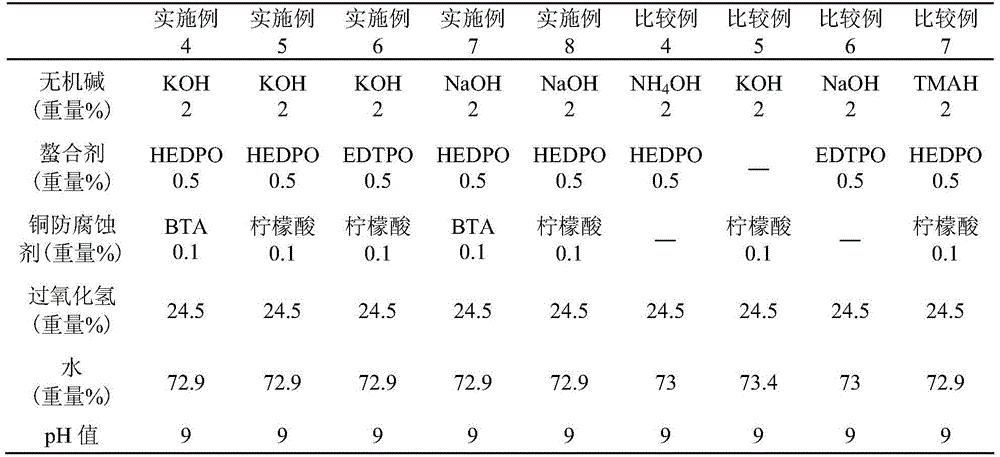

[0068] 1. The components and contents of Examples 4-8 and Comparative Examples 4-7 are shown in Table 4.

[0069] According to the components and proportions of Examples 4-8, first dilute the hydrogen peroxide with water to obtain a titanium oxide solution, then mix the rest of the components with the remaining water to obtain a titanium chelate solution, and finally use it in etching The oxidation solution and the chelating solution are mixed to obtain a titanium selective etching solution. According to the components and proportions of Comparative Examples 4-7, the same method was used to prepare a titanium contrast etching solution.

[0070] Wherein, the pH value is adjusted by boric acid, hydrochloric acid, sulfuric acid and / or phosphoric acid as a pH regulator of the titanium etching solution.

[0071] The composition and content of table 4 titanium selective etching solution, titanium contrast etching solution

[0072]

[0073] HEDPO: 1-Hydroxyethane-1,1'-diphosphat...

Embodiment 9 and comparative example 8

[0094] 1. Fabrication of semiconductor substrates

[0095] First, a thermal oxide film (SiO2) with a thickness of 10nm 2 ) on a 6 cm Si substrate by sputtering to deposit a 100nm thick Ti layer, and then on this Ti / SiO 2 On the / Si substrate, a 100nm-thick Cu stacked layer continues to be deposited. And in these Cu / Ti / SiO 2 The / Si substrate is covered with a positive film photoresistive resin coating (film thickness about 60 μm), and the model is formed by photolithography technology. After that, a Cu layer (Cu column) with a height (Cu column film thickness) of about 40 μm and a lateral width (Cu column width) of about 60 μm was deposited by electroplating, and then covered with Ni layer and Sn / Ag (96.5 :3.5) Alloy laminate (thickness about 15μm, width about 60μm). Finally, the photosensitive resistor resin coating is removed to obtain a semiconductor substrate.

[0096] The semiconductor substrate was cut into small pieces with a length of 1 cm x a width of 1 cm and us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com