Molybdenum disulfide nanosheet/polyimide based composite aerogel and preparation method thereof

A polyimide-based, composite aerogel technology, applied in the field of aerogels, can solve the problems of easy stacking and difficult dispersion, and achieve easy operation, simple preparation process, excellent thermal stability and flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

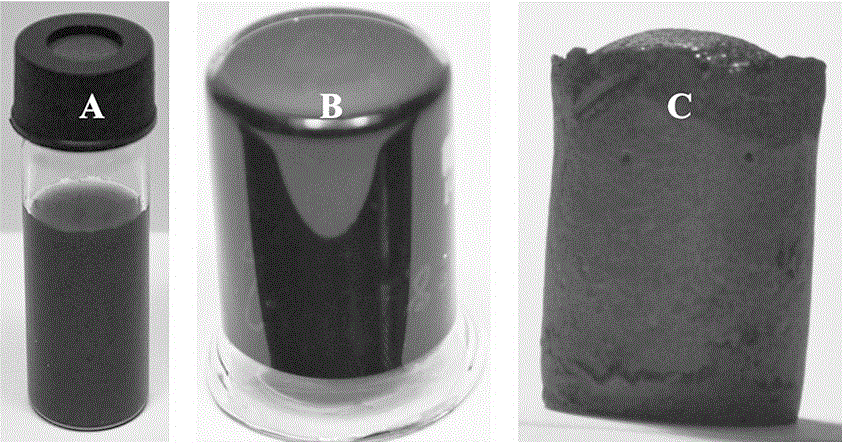

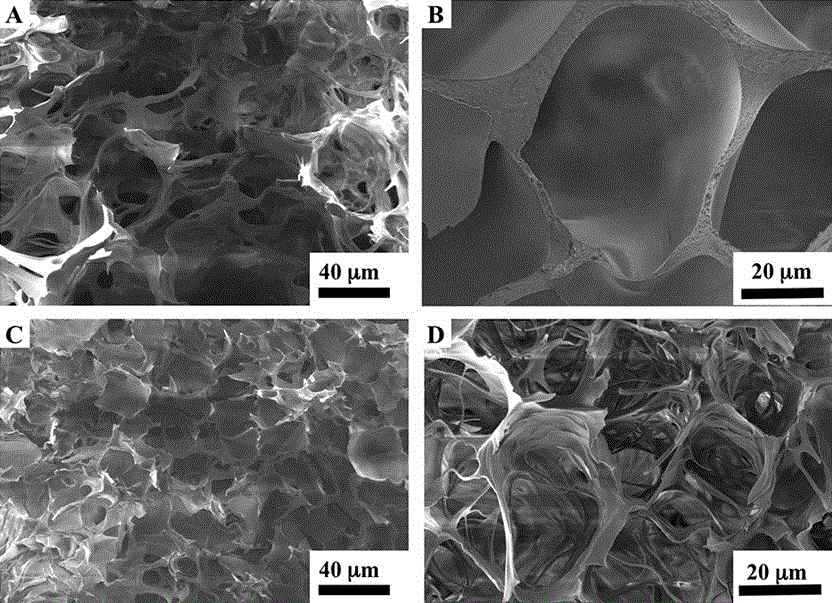

[0036] Embodiment 1, the present embodiment comprises the following steps:

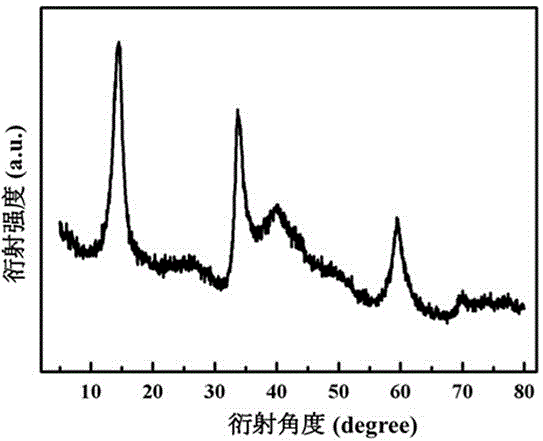

[0037] (1) Preparation of molybdenum disulfide nanosheets with good water dispersibility. Dissolve 1mmol ammonium molybdate tetrahydrate and 14mmol thiourea in 30mL deionized water, then transfer this solution to a 40mL hydrothermal kettle, and react at 200°C for 12h. After the reaction, the sample was repeatedly washed 3-5 times with deionized water and dried. Then the dried molybdenum disulfide nanosheets were dispersed in deionized water at a concentration of 8mgmL -1 .

[0038] (2) The steps for preparing water-soluble polyamic acid are the same as our patent CN104355302A.

[0039] (3) Take 2.5mL of the prepared 8mgmL -1 Molybdenum disulfide nanosheet aqueous dispersion, add 8.5mL deionized water and 0.5g triethylamine, ultrasonic 0.5h. Put 1 g of water-soluble polyamic acid fiber into the aqueous dispersion of molybdenum disulfide nanosheets containing triethylamine, stir to dissolve, and th...

Embodiment 2

[0041] Embodiment 2, this embodiment comprises the following steps:

[0042] Change the ratio of molybdenum disulfide nanosheets and polyamic acid to 5:100, that is, take 6.25mL of prepared 8mgmL -1 Molybdenum disulfide nanosheet aqueous dispersion, add 4.75mL deionized water and 0.5g triethylamine, ultrasonic 0.5h. denoted as MoS 2 / PI-5.

Embodiment 3

[0043] Embodiment 3, this embodiment comprises the following steps:

[0044] Change the ratio of molybdenum disulfide nanosheets and polyamic acid to 8:100, that is, take 10mL of prepared 8mgmL -1 Add 1mL of deionized water and 0.5g of triethylamine to the aqueous dispersion of molybdenum disulfide nanosheets, and ultrasonicate for 0.5h, and the rest are the same as in implementation 1. for MoS 2 / PI-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com