Silicon dioxide aerogel foaming cement

A technology of silica and foamed cement, which is applied in the field of airgel foamed cement, can solve the problems of fire prevention, waterproof, and thermal insulation that cannot meet people's requirements, and achieve good water resistance, good sound insulation effect, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

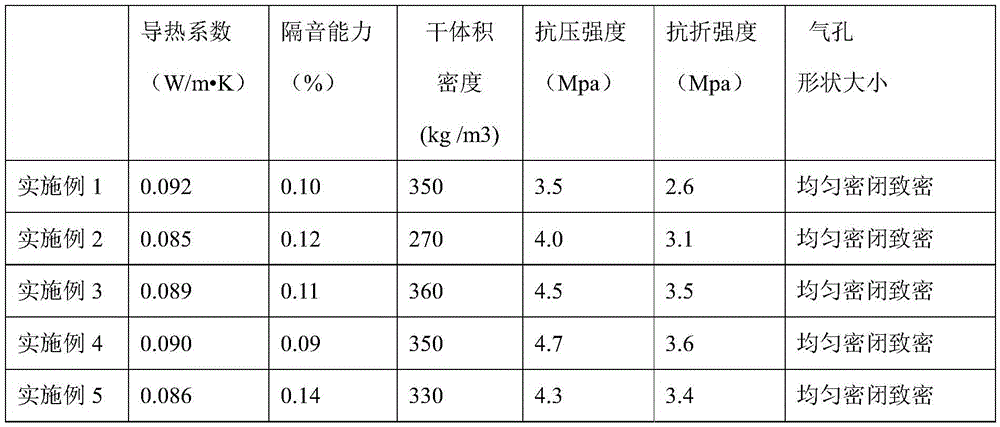

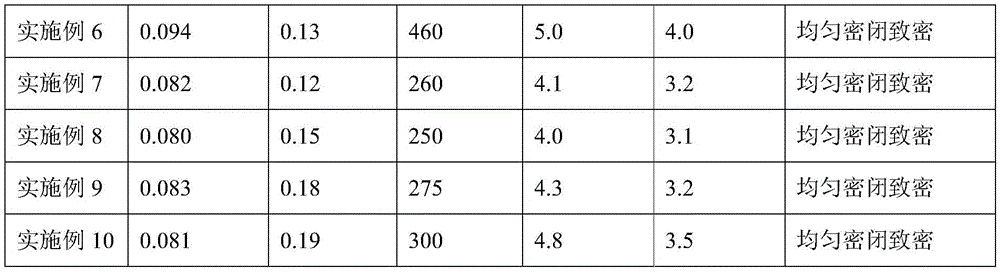

Examples

Embodiment 1

[0026] Example 1: Weigh 50 parts of ordinary silicon cement, 10 parts of silica airgel, 6 parts of micro-silica fume, and 5 parts of fly ash, all used for dry mixing and stirring; weigh appropriate amount of water, and heat the water to 42°C , add the powder into water, add 4 parts of coagulant water glass, 2 parts of water reducer sodium lignosulfonate, 6 parts of foam stabilizer silicone amide, stir evenly, add 10 parts of foaming agent rosin soap, Stir slightly, pour into the mold, and demould after 6 hours to obtain a foamed cement sample.

Embodiment 2

[0027] Example 2: Weigh 35 parts of ordinary silicon cement, 20 parts of silica airgel, 4 parts of micro-silica fume, and 10 parts of fly ash, all used for dry mixing and stirring; weigh appropriate amount of water, and heat the water to 42°C , put the powder into water, add 4 parts of coagulant water glass, 2 parts of water reducer sodium lignosulfonate, 5 parts of foam stabilizer silicone amide, stir evenly, add foaming agent dodecylbenzene 15 parts of sodium sulfonate, stirred slightly, poured into a mold, demolded after 6 hours to obtain a foamed cement sample.

Embodiment 3

[0028] Example 3: Weigh 55 parts of ordinary silicon cement, 15 parts of silica airgel, 6 parts of micro-silica fume, and 20 parts of fly ash, all used for dry mixing and stirring; weigh an appropriate amount of water, and heat the water to 42°C , add the powder into water, add 4 parts of coagulant water glass, 2 parts of water reducer sodium lignosulfonate, 4 parts of foam stabilizer silicone amide, stir evenly, add 10 parts of foaming agent rosin soap, Stir slightly, pour into the mold, and release the cement sample after 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com