A microwave-ultrasonic assisted compound solvent extraction method of oat bran oil and its full utilization in cosmetics

An oat bran oil, ultrasonic-assisted technology, which is applied to cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve problems such as inability to effectively extract oat lipids, and achieve the effects of low processing cost, efficient extraction, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

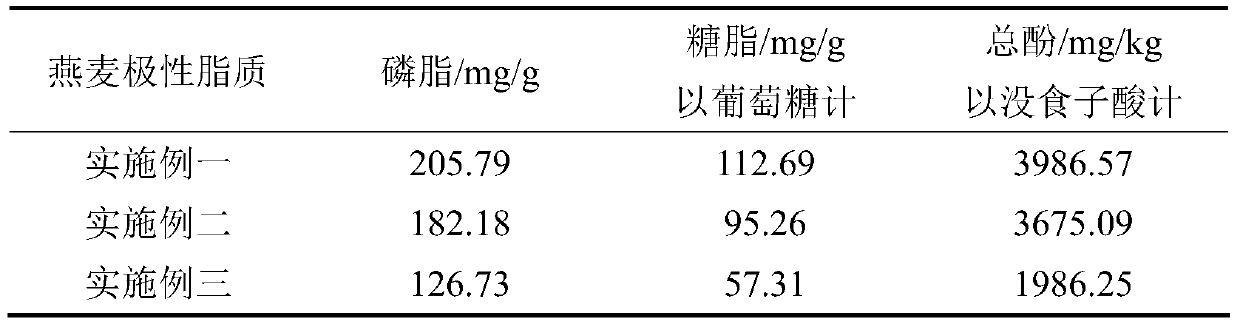

Embodiment 1

[0030] 1. Weigh 20g of oat bran, put it into the reactor, add 240mL of n-hexane, soak it, put it into the microwave oven, connect the condensation reflux device, heat and extract intermittently under 100W microwave power for 240s, take it out and cool it to room temperature, Centrifuge under the condition of 30min / min, take the supernatant and evaporate in vacuum to obtain the crude oil of oat bran extracted by microwave-ultrasonic.

[0031] 2. Heat the crude oat bran oil to 60° C., add deionized water at the same temperature with an oil weight (mass) of 10%, stir for 30 minutes, cool to room temperature, and centrifuge to obtain degummed oat bran oil and colloid, that is, oat polar lipid.

[0032] 3. Take the degummed oat bran oil in an Erlenmeyer flask, add 1% glycerin of oil weight (mass) and mix evenly. After heating to 70°C, add 2% lipase Novozym 435 and mix evenly. Stir to start the esterification and deacidification reaction to obtain the deacidified oat bran oil.

Embodiment 2

[0034] 1. Weigh 40g of oat bran, put it into a reactor, add 240mL of n-hexane:ethanol (1:4), soak it, put it in a microwave oven, connect a condensing reflux device, and heat and extract it intermittently for 120s under 200W microwave power. Take it out and cool it down to room temperature, centrifuge at 4000r / min for 30min, take the supernatant and vacuum rotary evaporation to obtain the crude oil of oat bran extracted by microwave-ultrasonic.

[0035] 2. Heat the crude oat bran oil to 70° C., add deionized water at the same temperature with 5% oil weight (mass), stir for 30 minutes, cool to room temperature, and centrifuge to obtain degummed oat bran oil and colloid, that is, oat polar lipid.

[0036] 3. Take the degummed oat bran oil in an Erlenmeyer flask, add 5% glycerin of oil weight (mass) and mix evenly. After heating to 60°C, add 5% lipase Novozym 435 and mix evenly. Stir to start the esterification and deacidification reaction to obtain the deacidified oat bran oil. ...

Embodiment 3

[0038] 1. Weigh 60g of oat bran, put it into the reactor, add 240mL of ethanol, soak it, put it into the microwave oven, connect the condensation reflux device, heat and extract intermittently under 300W microwave power for 60s, take it out and cool it to room temperature, Centrifuge for 30 min under the condition of min, take the supernatant and vacuum rotary evaporation, and obtain the crude oil of oat bran extracted by microwave-ultrasonic.

[0039] 2. Heat the crude oat bran oil to 80° C., add deionized water at the same temperature with an oil weight (mass) of 3%, stir for 30 minutes, cool to room temperature, and centrifuge to obtain degummed oat bran oil and colloid, that is, oat polar lipid.

[0040] 3. Take the degummed oat bran oil in an Erlenmeyer flask, add glycerin with 10% oil weight (mass) and mix evenly. After heating to 50°C, add 10% lipase Novozym 435 and mix evenly. Stir to start the esterification and deacidification reaction to obtain the deacidified oat b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com