Method for improving saccharopolyspora spinosa spinosad fermentation yield

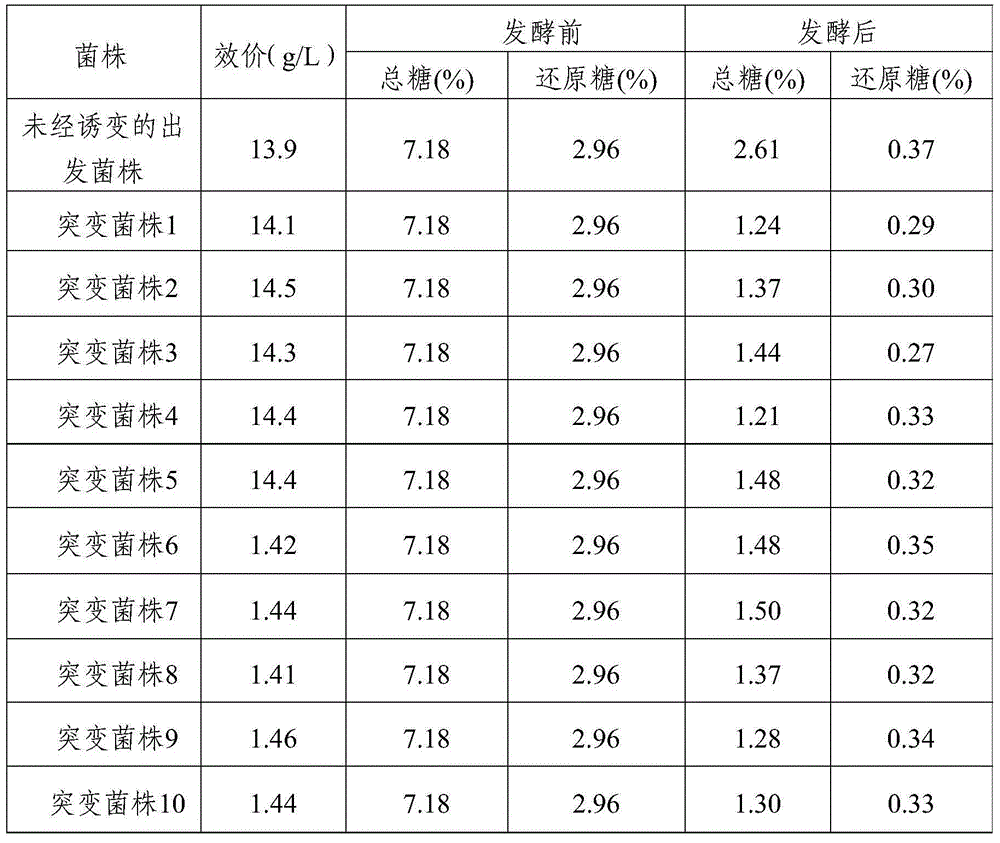

A technology of Saccharopolyspora spinosa and spinosad, which is applied in the field of improving the yield of spinosad fermentation of Saccharopolyspora spinosa, can solve the problems of increasing waste of resources, residues, and low utilization rate of starch, and achieve the reduction of total sugar and Non-reducing sugar content, avoiding very sticky, excellent high-yield performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] According to one embodiment of the present invention, the method is carried out according to the following steps:

[0037] Step 1: performing ultraviolet compound streptomycin mutagenesis on Saccharopolyspora spinosa for the first starch utilization ability screening to obtain the first mutant strain;

[0038] Step 2: performing a second starch utilization ability screening on the first mutant strain after mutagenesis with 5-fluorouracil to obtain a second mutant strain;

[0039] Step 3: performing the third starch utilization ability screening on the second mutant strain after microwave-complexed streptomycin mutagenesis to obtain the third mutant strain;

[0040] Step 4: Perform the fourth starch utilization ability screening on the third mutant strain after mutagenesis with nitrosoguanidine and streptomycin to obtain the fourth mutant strain.

[0041] According to the method provided by the present invention, the pH value of the starch hydrolysis medium is 7.0-7.4, ...

Embodiment 1

[0048] Utilize 0.1mol / L, the phosphate buffer solution of pH6.5 is formulated as the concentration of 10 8 spore suspension per ml.

[0049] Preparation of separation medium: glucose 10g / L, soluble starch 20g / L, yeast extract powder 5g / L, enzyme hydrolyzed casein 5g / L, calcium carbonate 1g / L and agar 20g / L. Starvation medium: glucose 10g / L, magnesium sulfate 0.5g / L, potassium dihydrogen phosphate 1g / L, potassium chloride 0.5g / L. Starch hydrolysis medium: soluble starch 10g / L, dipotassium hydrogen phosphate 0.3g / L, magnesium carbonate 1g / L, sodium chloride 0.5g / L, potassium nitrate 1g / L and agar 20g / L, pH 7.2. The iodine solution is composed of iodine tablet 3g / L and potassium iodide 6g / L, prepared with water.

[0050] Slant medium composition: cornstarch 25g / L, corn steep liquor 20g / L, yeast extract 10g / L and agar 20g / L, pH value 7.0, prepared with water; sterilized at 115°C for 20 minutes.

[0051] (1) Ultraviolet compound streptomycin mutagenesis:

[0052] 1) Ultraviolet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com