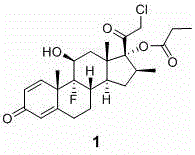

One-pot preparation method of clobetasol propionate intermediate

A technology for clobetasol propionate and intermediates, which is applied in the field of one-pot preparation of clobetasol propionate intermediates, can solve problems not involved in process improvement of betamethasone-17-propionate, and achieve shortening The effect of production cycle, saving raw and auxiliary materials, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Add 50mL of 2-Me-THF to a 250mL three-neck round bottom flask, start stirring, add 20g of betamethasone, wash the bottle wall with 10mL of 2-Me-THF, control the temperature at 25°C~30°C, and add 13.47g of triethyl orthopropionate , 4.82g p-toluenesulfonic acid monohydrate, heat preservation reaction 3h, TLC detection reaction is complete. Add 30% sodium sulfite aqueous solution to terminate the reaction, adjust the pH to 7~8, concentrate under reduced pressure at 40°C until there is almost no 2-Me-THF; wash into 100mL water for water analysis, suction filter after 0.5h, wash with 1000mL water, and dry at 80°C Betamethasone-17-propionate. After constant weight, detection: HPLC content: 98.08%, maximum simple impurity: 0.89%, raw material point: 0.27%, mass yield 113.5%.

example 2

[0028] Add 150mL of ethyl acetate to a 250mL three-neck round bottom flask, start stirring, add 20g of betamethasone, wash the bottle wall with 10mL of ethyl acetate, control the temperature at 35°C~40°C, add 10.26g of trimethyl orthopropionate, 3.51 g of p-toluenesulfonic acid, incubated for 3 hours, and TLC detected that the reaction was complete. Add 40% sodium bicarbonate aqueous solution to terminate the reaction, adjust the pH to 7~8, concentrate under reduced pressure at 40°C until almost no ethyl acetate is present; pour into 100mL water for water analysis, suction filter after 0.5h, wash with 1000mL water, and dry at 80°C Betamethasone-17-propionate. After constant weight, detection: HPLC content: 97.32%, maximum simple impurity: 1.27%, raw material point: 0.32%, mass yield 113.3%.

example 3

[0030] Add 110mL of methyl tert-butyl ether into a 250mL three-necked round-bottomed flask, start stirring, add 20g of betamethasone, wash the bottle wall with 10mL of methyl tert-butyl ether, control the temperature at 30°C~35°C, and add 20.51g of propane Acetate trimethyl ester, 1g sulfuric acid, heat preservation reaction 3h, TLC detects that the reaction is complete. Add 20% potassium carbonate aqueous solution to terminate the reaction, adjust the pH to 7~8, concentrate under reduced pressure at 40°C until almost no methyl tert-butyl ether is present; pour into 100mL water for water analysis, suction filter after 0.5h, wash with 1000mL water, and wash with water for 80 °C drying to obtain betamethasone-17-propionate. After constant weight, detection: HPLC content: 97.53%, maximum simple impurity: 1.02%, raw material point: 0.38%, mass yield 112.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com