A kind of cross-linked hyaluronic acid dry powder and its preparation method and application

A technology of cross-linking hyaluronic acid and hyaluronic acid, which is applied in the fields of pharmaceutical formulations, toiletry preparations, cosmetic preparations, etc., and can solve the problems of large-scale industrial production, hyaluronic acid long-chain break degradation, and impact on dialysis operations. Gel use effect and other issues, to achieve the effect suitable for large-scale production, thickening and skin feeling, and convenient for clinical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

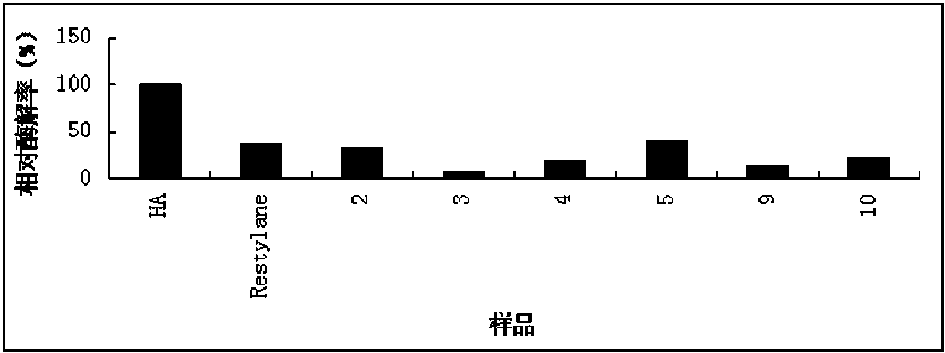

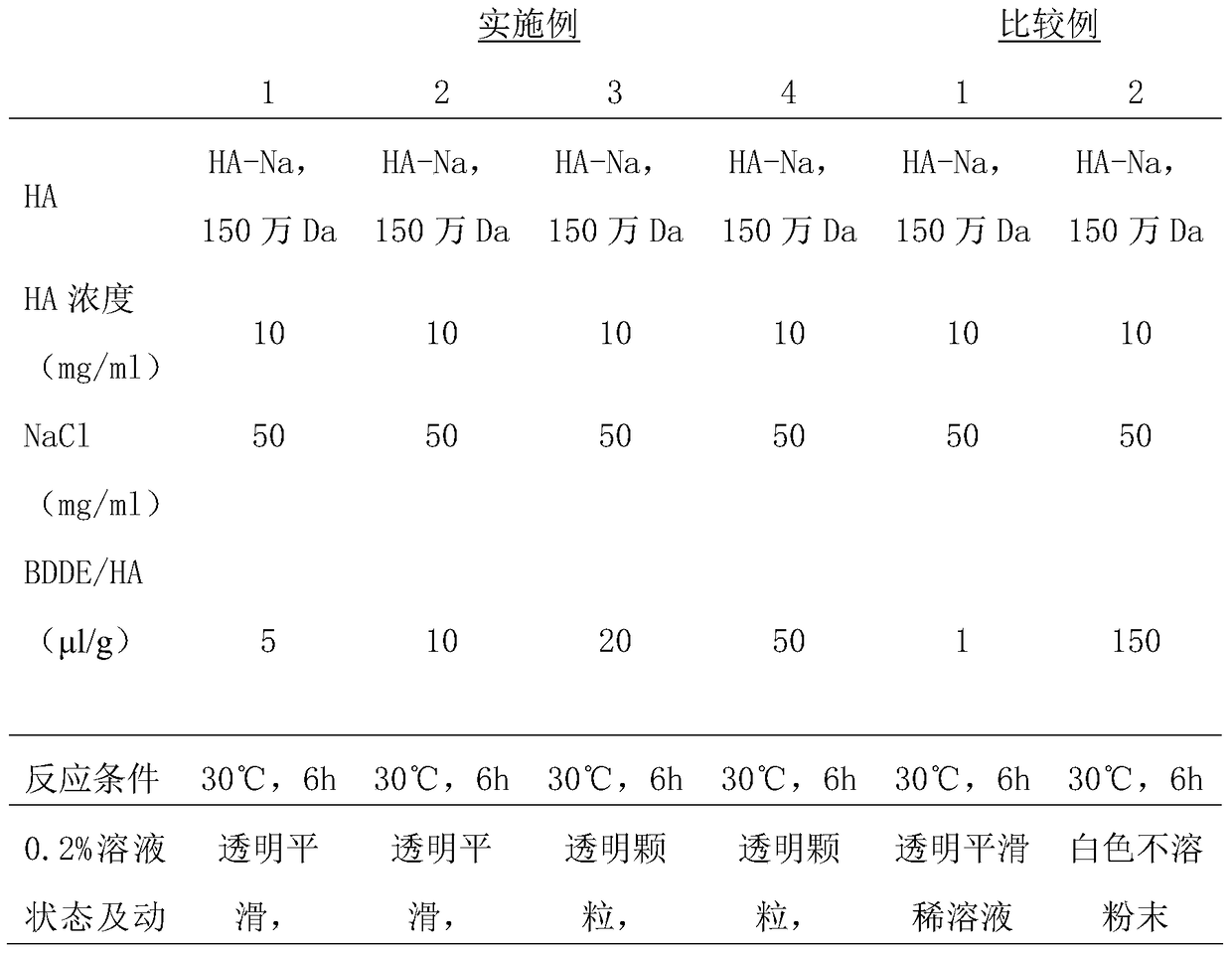

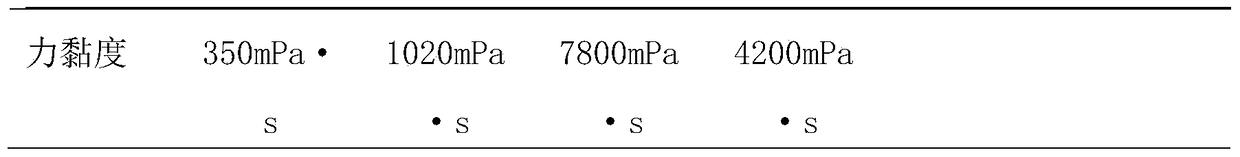

[0038] Accurately take 5 μl of 1,4-butanediol diglycidyl ether and add it to 100mL of sodium chloride solution (50mg / mL). After mixing, weigh 1g of sodium hyaluronate (molecular weight: 1.5 million Da) and dissolve it in the above solution. After the sodium hyaluronate is fully dissolved, gradually add 186ml of ethanol until the sodium hyaluronate precipitates a white precipitate. After the whole reaction system showed a solid-liquid suspension system, it was stirred and reacted at 30° C. for 6 hours. Then let stand and discard the supernatant. Finally, wash and dehydrate with ethanol for 3 times, then suction filter and discard the filtrate, put the wet powder in a vacuum drying oven at 25°C and dry it to make a dry cross-linked sodium hyaluronate powder. Weigh 0.2 g of the dry powder and add it to 100 ml of purified water to dissolve, and as a result, a colorless, transparent, smooth and viscous solution is obtained, with a kinetic viscosity of 350 mPa s, which is higher th...

Embodiment 2

[0040]Accurately take 10 μl of 1,4-butanediol diglycidyl ether and add it to 100 mL of sodium chloride solution (50 mg / mL). After mixing, weigh 1 g of sodium hyaluronate (molecular weight: 1.5 million Da) and dissolve it in the above solution. After the sodium hyaluronate is fully dissolved, gradually add 186ml of ethanol until the sodium hyaluronate precipitates a white precipitate. After the whole reaction system showed a solid-liquid suspension system, it was stirred and reacted at 30° C. for 6 hours. Then let stand and discard the supernatant. Finally, it was washed and dehydrated with ethanol for 3 times, and the filtrate was discarded by suction filtration. The wet powder was dried in a vacuum drying oven at 30°C to prepare a dry cross-linked sodium hyaluronate powder. Weigh 0.2 g of the dry powder and add it to 100 ml of purified water to dissolve, and as a result, a colorless, transparent, smooth and viscous solution is obtained, with a dynamic viscosity of 1020 mPa s...

Embodiment 3

[0042] Accurately take 20μl of 1,4-butanediol diglycidyl ether and add it to 100mL of sodium chloride solution (50mg / mL). After mixing, weigh 1g of sodium hyaluronate (molecular weight: 1.5 million Da) and dissolve it in the above solution. After the sodium hyaluronate is fully dissolved, gradually add 186ml of ethanol until the sodium hyaluronate precipitates a white precipitate. After the whole reaction system showed a solid-liquid suspension system, it was stirred and reacted at 30° C. for 6 hours. Then let stand and discard the supernatant. Finally, it was washed and dehydrated with ethanol for 3 times, and the filtrate was discarded by suction filtration. The wet powder was dried in a vacuum drying oven at 40°C to prepare a dry cross-linked sodium hyaluronate powder. Weigh 0.2 g of the dry powder and add it to 100 ml of purified water to dissolve, and as a result, a colorless, viscous solution with transparent particles is obtained, and its dynamic viscosity is 7800 mPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com