Light-sensitive nanometer silicon dioxide and method for preparing same

A nano-silica, silica technology, applied in the direction of coating, can solve the problems of inability to achieve bonding, cross-linking and curing, achieve good application prospects, avoid agglomeration, and improve the effect of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of nano-silica dispersion:

[0054] Mix 30ml of ethanol, 1.35ml of ammonia water and 0.6ml of deionized water, raise the temperature to 60°C, then add 1.5ml of tetraethyl orthosilicate to the solution, continue to stir and react at 60°C for 12 hours to obtain carbon dioxide Silicon nanoparticle dispersion.

[0055] (2) Surface modification of silica:

[0056] Adding 4ml of mass concentration to the silica nanoparticle dispersion obtained in step (1) is the toluene solution of Bp of 200mg / ml (the feeding volume ratio of Bp to tetraethyl orthosilicate is about 32:60), continue Stir at 60°C and react for 24 hours; then, centrifuge the nanoparticles, wash them twice with ethanol, and dry them in vacuum to obtain photosensitive nano-silica.

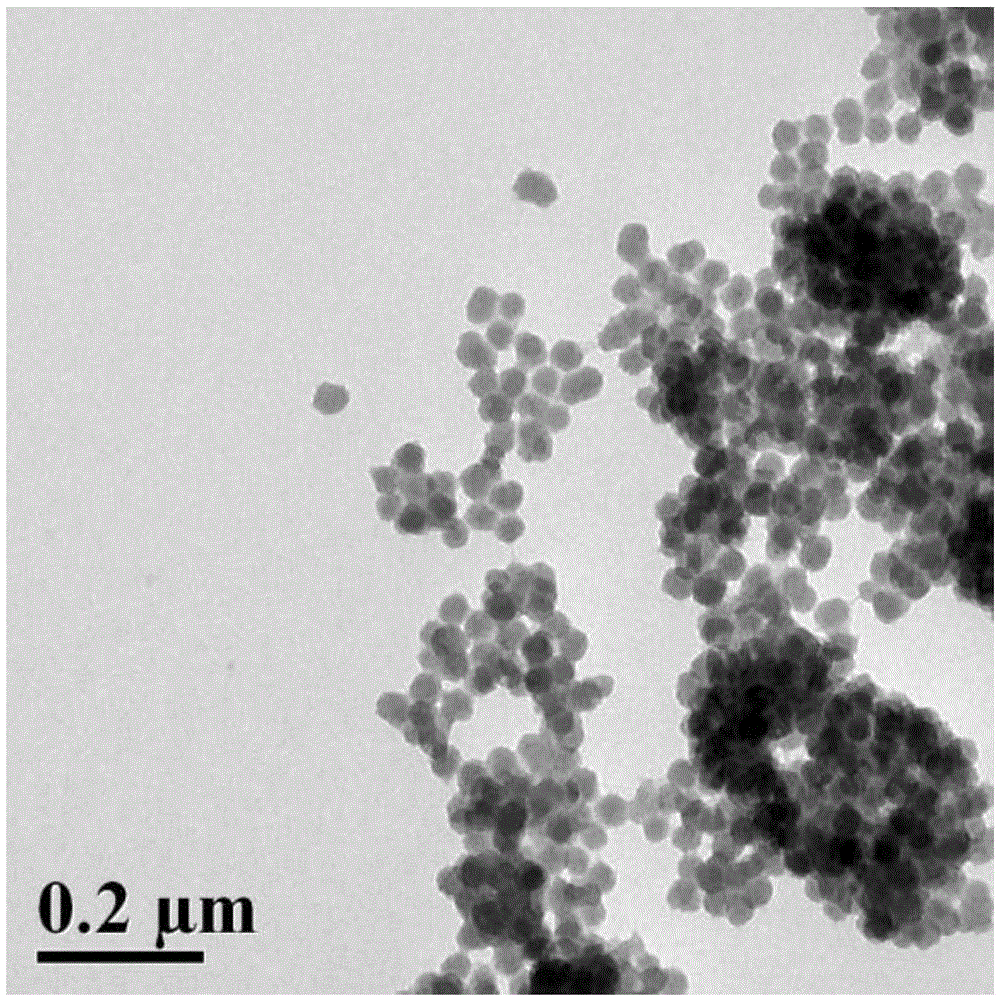

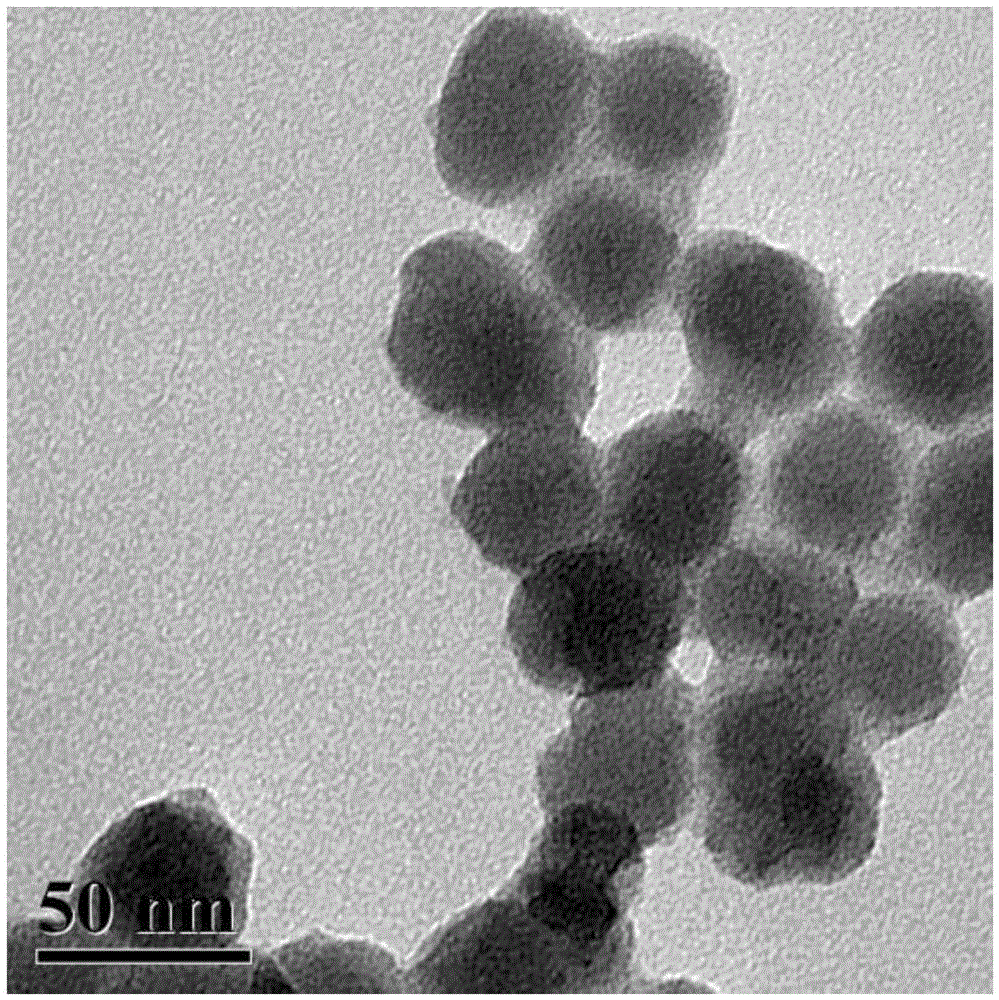

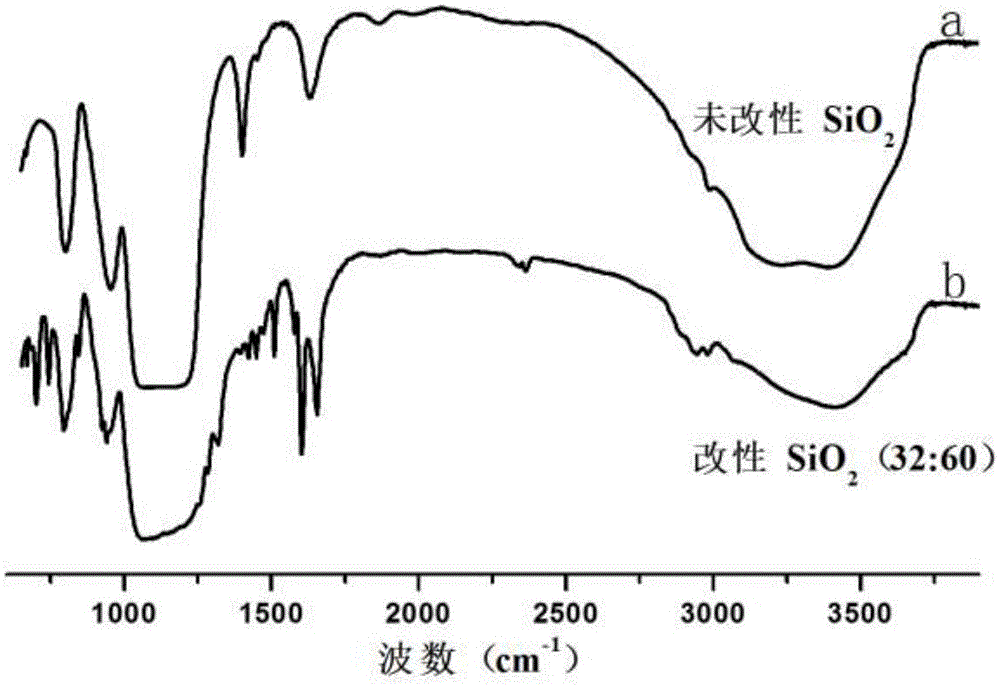

[0057] Its TEM pictures are as Figure 1-a , Figure 1-b As shown, the particle size of the silica core is about 30nm, and the excess silane coupling agent makes the silica adhere to each other. Its infrared spectru...

Embodiment 2

[0059] (1) Preparation of nano-silica dispersion:

[0060] Mix 30ml of ethanol, 1.35ml of ammonia water and 0.6ml of deionized water, raise the temperature to 60°C, then add 1.5ml of tetraethyl orthosilicate to the solution, continue to stir and react at 60°C for 12 hours to obtain carbon dioxide Silicon nanoparticle dispersion.

[0061] (2) Surface modification of silica:

[0062] Add the toluene solution (the feed volume ratio of Bp and tetraethyl orthosilicate is about 16:60) of the Bp whose mass concentration is 200mg / ml to the silicon dioxide nanoparticle dispersion liquid that step (1) obtains, continue Stir at 60°C and react for 24 hours; then, centrifuge the nanoparticles, wash them twice with ethanol, and dry them in vacuum to obtain photosensitive nano-silica.

[0063] Its TEM pictures are as Figure 4-a , Figure 4-b As shown, the particle size of the silica core is about 30nm, and the excess silane coupling agent makes the silica adhere to each other. From i...

Embodiment 3

[0065] (1) Preparation of nano-silica dispersion:

[0066] Mix 30ml of ethanol, 1.35ml of ammonia water and 0.6ml of deionized water, raise the temperature to 60°C, then add 1.5ml of tetraethyl orthosilicate to the solution, continue to stir and react at 60°C for 12 hours to obtain carbon dioxide Silicon nanoparticle dispersion.

[0067] (2) Surface modification of silica:

[0068] Add the mass concentration of 0.5ml to the toluene solution of the Bp of 200mg / ml in the silica nanoparticle dispersion that step (1) obtains (the feeding volume ratio of Bp and tetraethyl orthosilicate is about 4:60), Continue to stir at 60° C. and react for 24 hours; after that, the nanoparticles are centrifuged, washed twice with ethanol, and dried in vacuum to obtain photosensitive nano-silicon dioxide.

[0069] Its TEM pictures are as Figure 5-a , Figure 5-b As shown, the particle size of the silica core is about 30nm, and the excess silane coupling agent makes the silica adhere to each o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com