High-lubricity and ecological safety water-based cutting fluid and preparation method thereof

An ecologically safe and lubricious technology, which is applied in the direction of lubricating compositions, base materials, and the petroleum industry, can solve problems that affect the health of users of ecological environment products and affect the overall quality of cutting fluids, and achieve good ecological safety and overcome Poor oxidation stability and remarkable antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

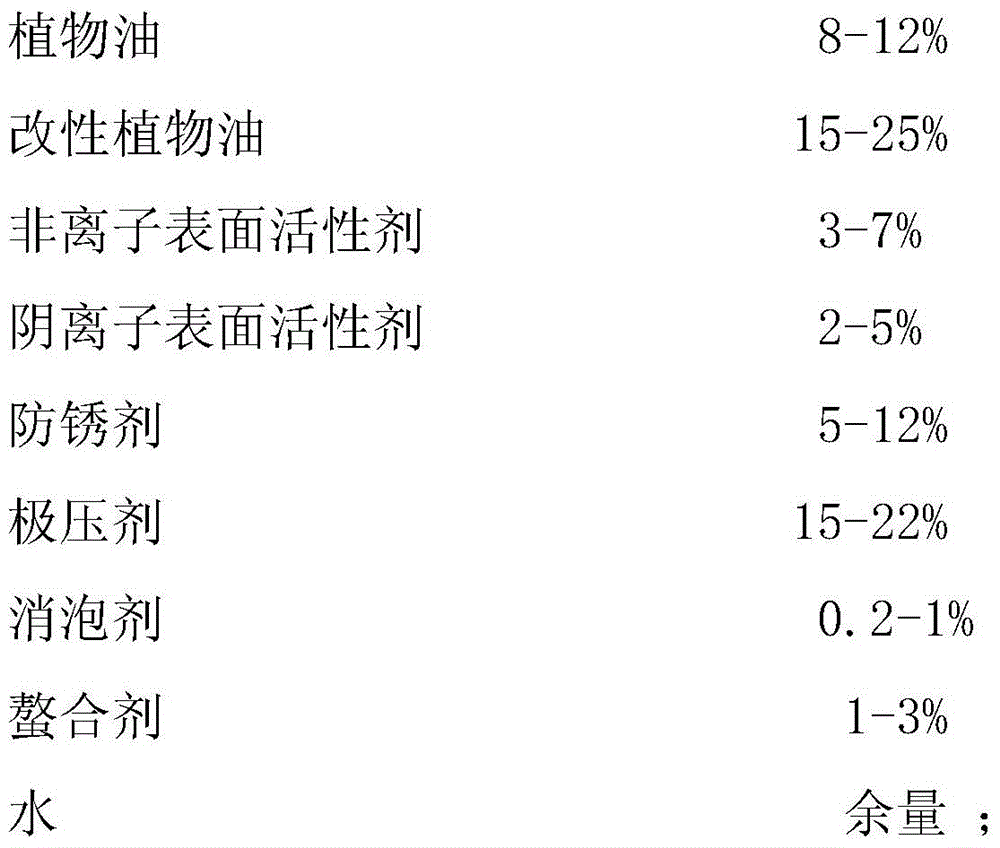

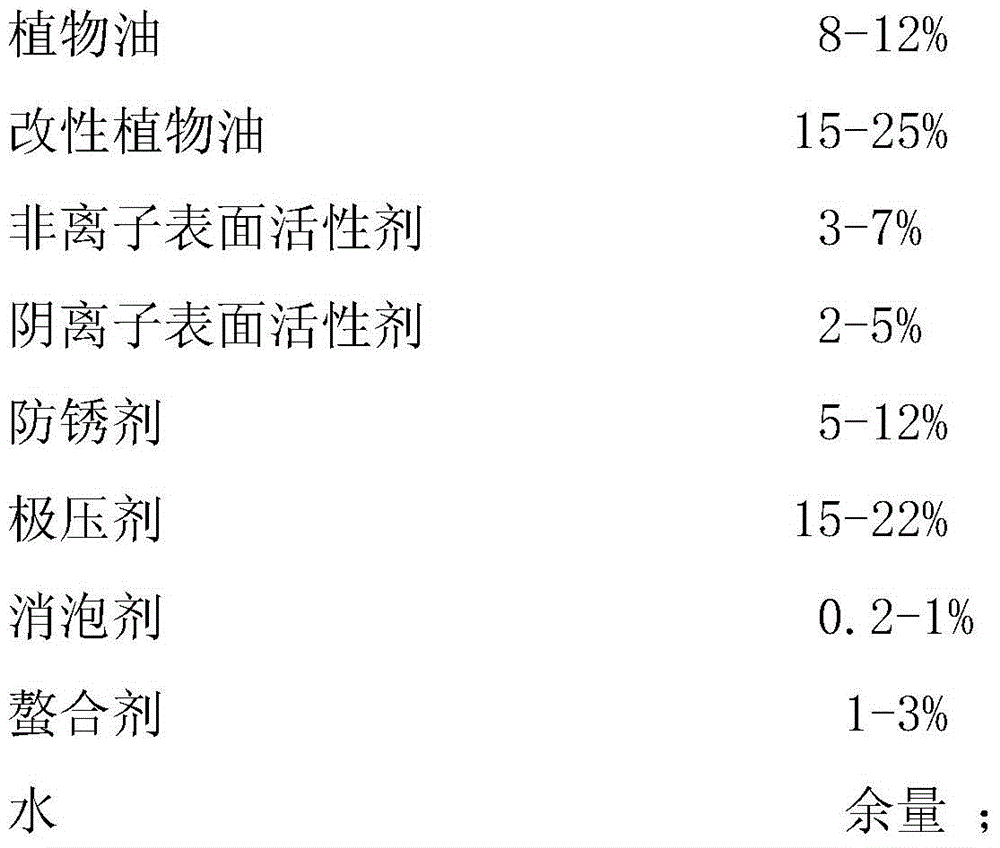

Method used

Image

Examples

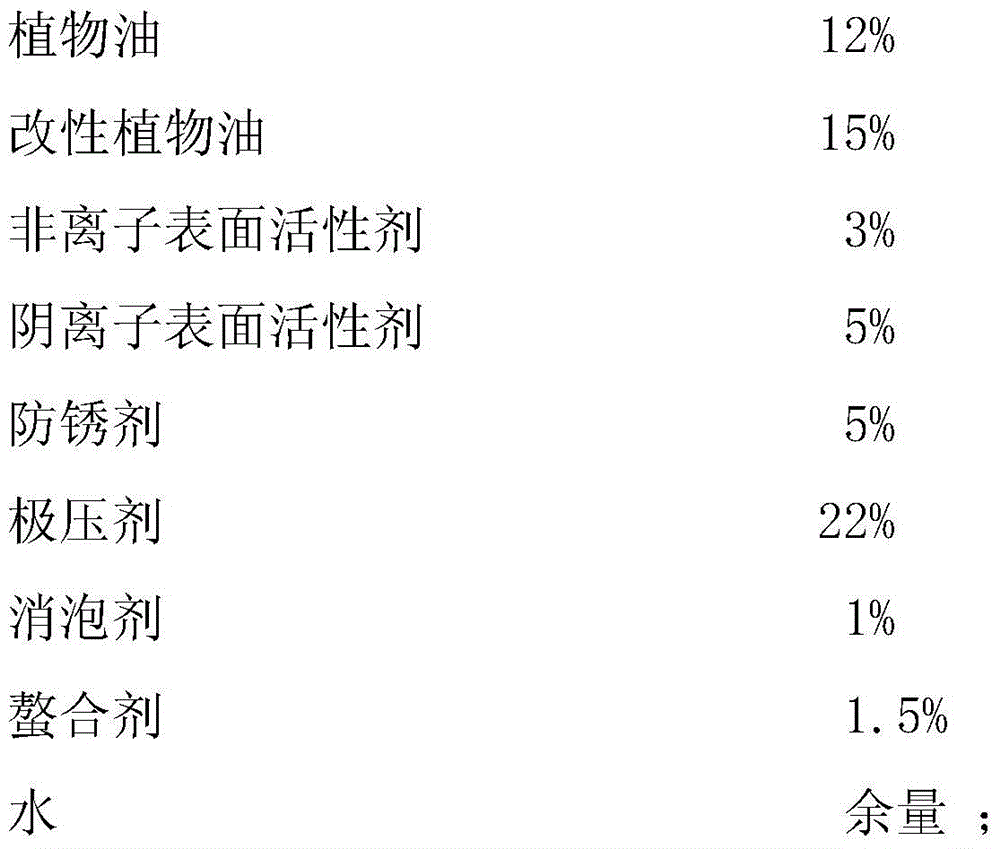

Embodiment 1

[0034] 1), each component is weighed by percentage mass: 120g of coconut oil; 50g each of epoxidized soybean oil, epoxidized rapeseed oil and hydrogenated castor oil; 30g of C8 alkyl glycosides; 50g of sodium C18 fatty acid methyl ester sulfonate; 50g of borax Each 110g of diethanolamine borate and oleic acid diethanolamide borate; Simethicone 10g; Diethylenetriaminepentamethylenephosphonic acid 5g; Maleic acid 10g; Water is 355g; 1kg;

[0035] 2), heating and stirring the coconut oil, epoxidized soybean oil, epoxidized rapeseed oil and hydrogenated castor oil weighed in step 1) at 40-60° C. to obtain the first mixture;

[0036] 3), heating and stirring the alkyl glucoside, sodium fatty acid methyl ester sulfonate, and 150 g of water weighed in step 1) at 40-60° C. to obtain a second mixture;

[0037] 4) heating, stirring and mixing the first mixture obtained in step 2) and the second mixture obtained in step 3) at 40-60° C. to obtain a third mixture;

[0038] 5), in the thi...

Embodiment 2

[0040] 1), each component is weighed by percentage mass: 110g of coconut oil; 90g of epoxidized soybean oil and hydrogenated castor oil; 40g of C10 alkyl glycoside; 30g of sodium C16 fatty acid methyl ester sulfonate; 80g of borax; triethanolamine borate and oleic acid diethanolamide borate 100g each; polyether modified silicone oil 5g; diethylenetriaminepentamethylene phosphonic acid and maleic acid each 5g; water is 345g; the sum of the components is 1kg;

[0041] 2), heating and stirring the coconut oil, epoxidized soybean oil, epoxidized rapeseed oil and hydrogenated castor oil weighed in step 1) at 40-60° C. to obtain the first mixture;

[0042] 3), heating and stirring the alkyl glucoside, sodium fatty acid methyl ester sulfonate, and 150 g of water weighed in step 1) at 40-60° C. to obtain a second mixture;

[0043] 4) heating, stirring and mixing the first mixture obtained in step 2) and the second mixture obtained in step 3) at 40-60° C. to obtain a third mixture;

[0...

Embodiment 3

[0046] 1), weigh each component by percentage mass: coconut oil 100g; Epoxidized rapeseed oil and hydrogenated castor oil each 100g; C12 alkyl glycoside 50g; C14 sodium fatty acid methyl ester sulfonate 40g; Borax 100g; Diethanolamine boric acid Esters, triethanolamine borate and oleic acid diethanolamide borate 50g each; dimethyl silicone oil 1g; polyether modified silicone oil 4g; diethylenetriaminepentamethylenephosphonic acid 15g; maleic acid 5g; 335g; the mass sum of each component is 1kg;

[0047] 2), heating and stirring the coconut oil, epoxidized soybean oil, epoxidized rapeseed oil and hydrogenated castor oil weighed in step 1) at 40-60° C. to obtain the first mixture;

[0048] 3), heating and stirring the alkyl glucoside, sodium fatty acid methyl ester sulfonate, and 150 g of water weighed in step 1) at 40-60° C. to obtain a second mixture;

[0049] 4) heating, stirring and mixing the first mixture obtained in step 2) and the second mixture obtained in step 3) at 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com