Flue gas denitration catalyst and preparation method thereof

A denitration catalyst and catalyst technology, which are applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of unsatisfactory water and sulfur resistance, difficult industrialization amplification, and low reaction activity, and achieve excellent catalytic performance. Active, sulfation-avoiding, deposit-relieving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 5

[0027] 1) Dissolving cerium salt, europium salt and template agent in 1L of water, stirring for the first time at room temperature to obtain a mixed solution;

[0028] 2) dissolving the solute in water to form a certain concentration of precipitant;

[0029] 3) Add the precipitating agent dropwise to the mixed solution under magnetic stirring to obtain the mixture, and stop the dropwise addition when the pH value of the liquid phase in the mixture reaches 10-14;

[0030] 4) heating the mixture to the first temperature in a water bath and keeping the temperature constant, then naturally cooling to room temperature to obtain the first product;

[0031] 5) The liquid phase in the first product is separated, and the obtained precipitate is dried; then roasted, and the obtained second product is tabletted, crushed, and sieved to obtain a powder of 40 mesh to 60 mesh. denitrification catalyst.

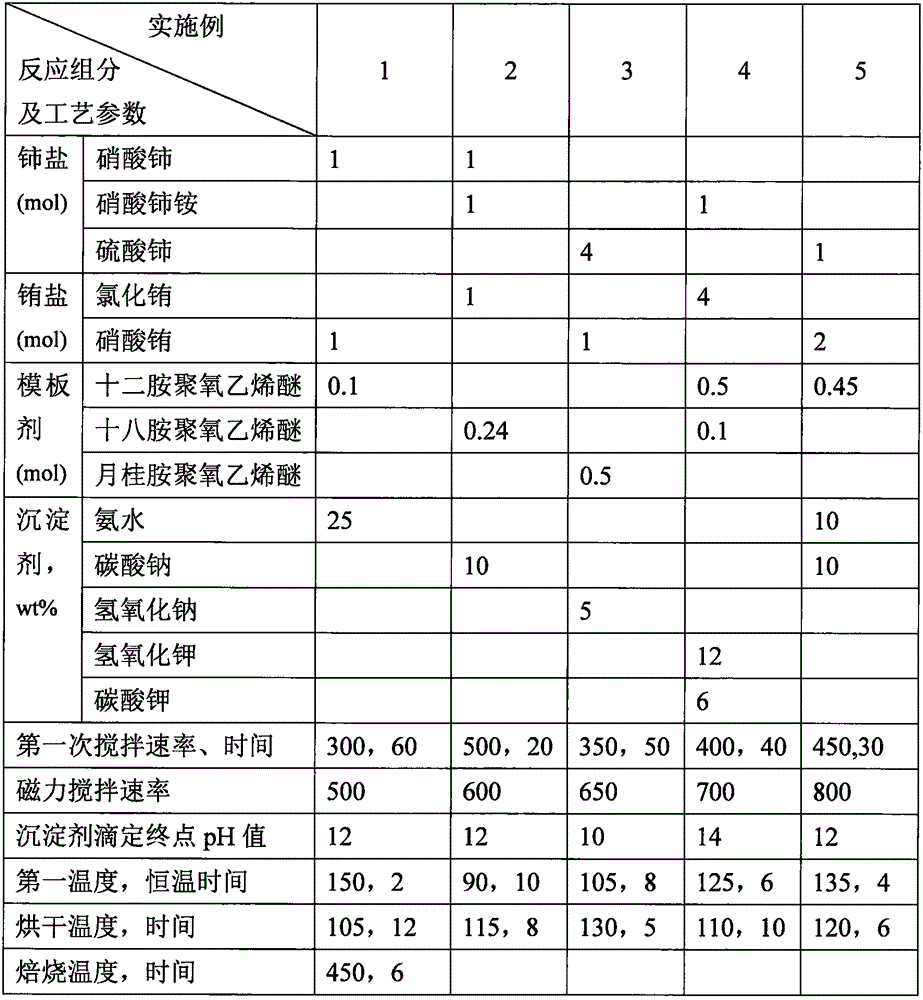

[0032] The dosages and process parameters of each component in Examples 1 to 5 are sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com