Preparation method of molecular sieve supported SCR (selective catalytic reduction) catalyst

A technology of SCR catalyst and molecular sieve, which is applied in the field of preparation of molecular sieve-supported SCR catalyst, can solve the problems of poor thermal stability, inability to meet usage requirements, toxicity of vanadium-based catalyst, etc., and achieve the effect of good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

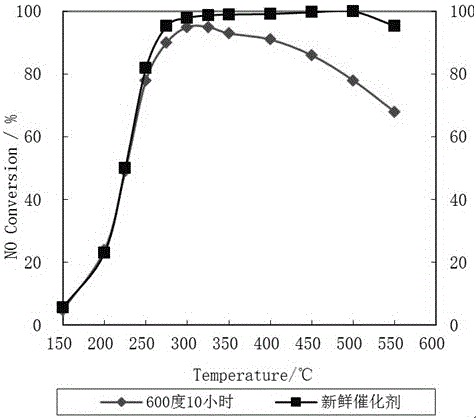

Image

Examples

Embodiment 1

[0023] A preparation method of a molecular sieve-loaded SCR catalyst, the precursor solution of copper (0.01mol / LCu(NO 3 ) 2 , 0.01mol / LFe (NO 3 ) 3 , 0.01mol / LMn (NO 3 ) 2 ), and molecular sieve (sapo34) was added to deionized water, and the mass ratio of copper precursor: molecular sieve: deionized water was 0.7 / 1 / 2.7. Stir evenly, perform ion exchange at room temperature for 1-3 hours; filter the suspension to obtain a filter cake, wash with deionized water, and filter again, and dry the washed filter cake at 130-180°C for 3- 5 hours, calcined at 400-600° C. for 2-3 hours to obtain Cu-sapo34 molecular sieve SCR catalyst powder.

[0024] Add Cu-sapo34 molecular sieve and binder (zirconium acetate) into deionized water, and the mass ratio of copper molecular sieve: binder: deionized water is 2.7 / 1 / 3.7. Stir evenly to form a slurry; then use a ball milling process to treat the slurry, control the particle size D90 to be less than 10 microns, and obtain a coating slurry; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com