Preparation method of nano oxide thin-film electrode for treating ammonia nitrogen wastewater

A nano-oxide and thin-film electrode technology, which is applied in the field of environmental engineering, can solve the problems of restricting photocatalytic technology and the difficulty of photocatalyst fixation, and achieve the effects of simple preparation process, good cleaning effect and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

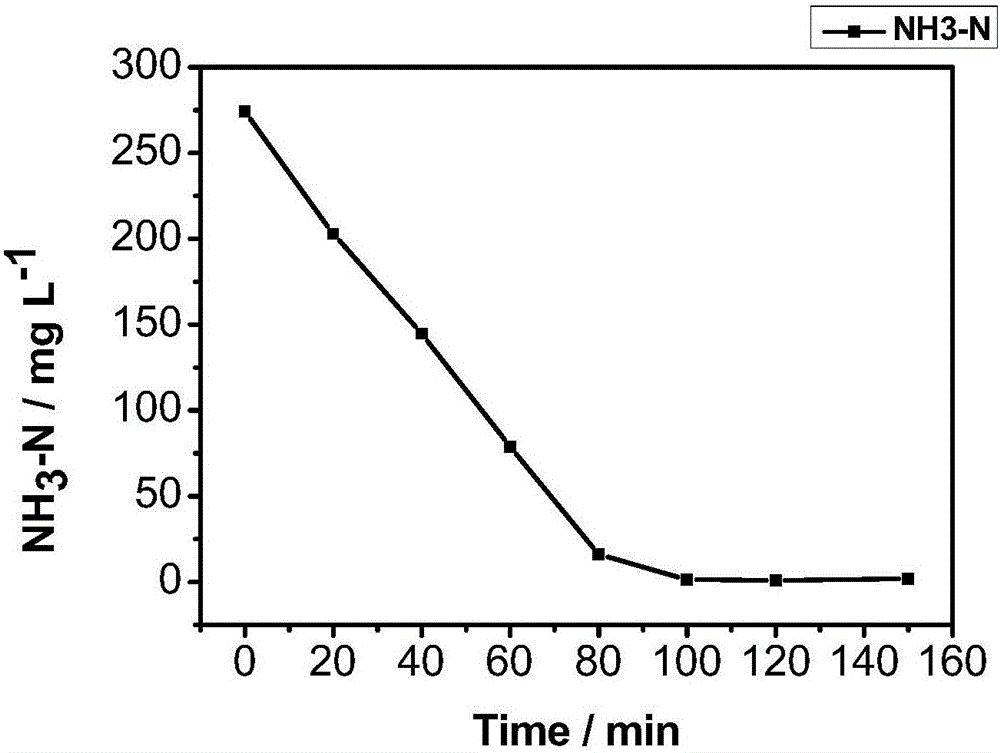

[0058] Wastewater indicators: ammonia nitrogen 280mg / L, chloride ion concentration 0.5mol / L, TDS 8500mg / L, pH 6.7.

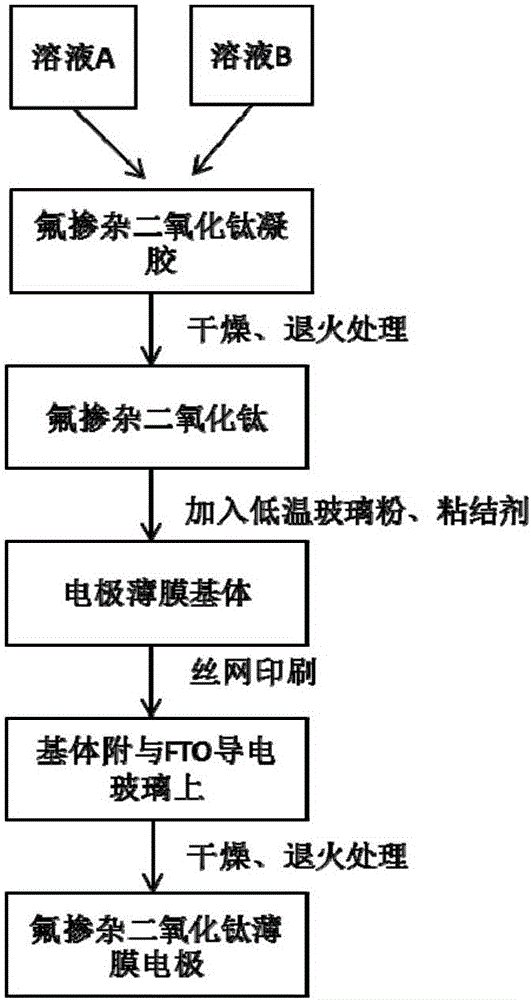

[0059] Tetrabutyl titanate and absolute ethanol are prepared in a volume ratio of 1:1 to prepare solution A; to ammonium fluoride ethanol solution with a mass fraction of 10%, add acetic acid in a volume ratio of 3:1, press Add concentrated hydrochloric acid at a volume ratio of 30:1 to prepare solution B; slowly add solution B to solution A dropwise to prepare a gel; dry the gel at 100°C and grind it evenly, then anneal at 600°C treatment to obtain fluorine-doped titanium dioxide nanoparticles; cut the FTO conductive glass into a size of 10×10cm; after cleaning, dry it at 100°C for use; mix turpentine oil with alcohol and ethyl cellulose in a ratio of 20:1 Stir in a beaker at 100°C until ethyl cellulose is completely dissolved in turpentine through alcohol; mix low-temperature glass powder and fluorine-doped titanium dioxide in a mass ratio of 1:2; add an appro...

example 2

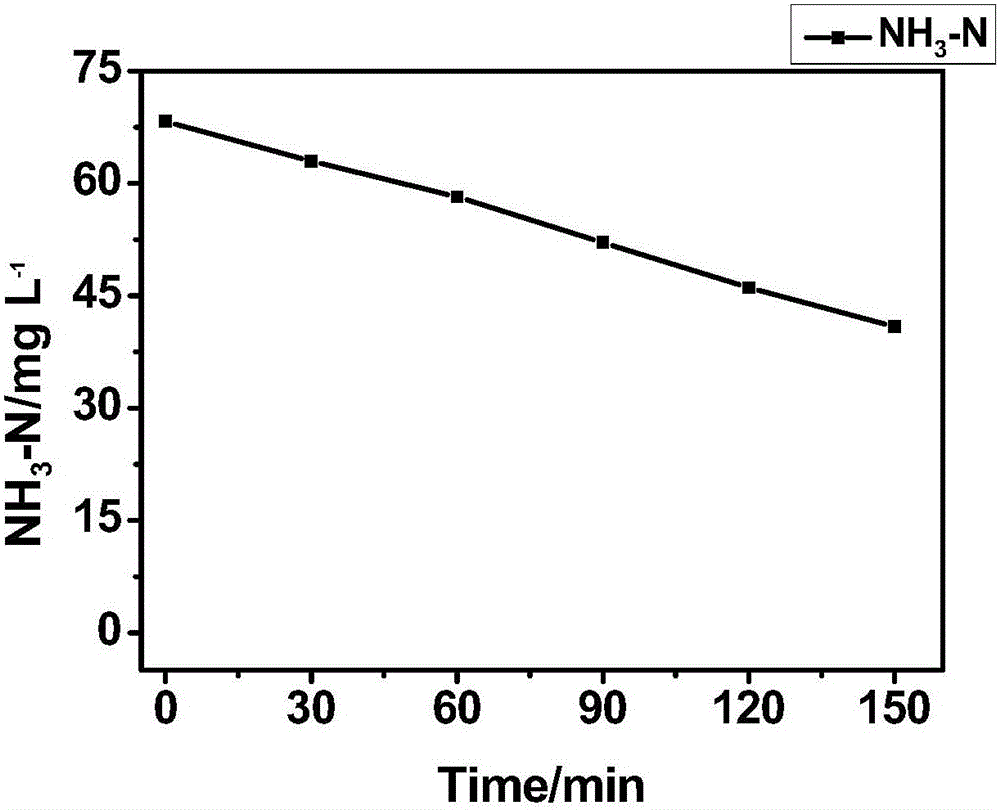

[0061] Wastewater indicators: ammonia nitrogen 70mg / L, TDS 6200mg / L, pH 7.1.

[0062] Tetrabutyl titanate and absolute ethanol are prepared in a volume ratio of 1:2 to prepare solution A; to the ammonium fluoride ethanol solution with a mass fraction of 15%, add acetic acid in a volume ratio of 2:1, and press Add concentrated hydrochloric acid at a volume ratio of 60:1 to prepare solution B; slowly add solution B to solution A dropwise to prepare a gel; dry the gel at 100°C and grind it evenly, then anneal at 500°C treatment to obtain fluorine-doped titanium dioxide nanoparticles; cut the FTO conductive glass into a size of 5 × 5cm; after cleaning, dry it at 110°C for use; mix turpentine oil with alcohol and ethyl cellulose in a ratio of 20:1 In a beaker, stir at 100°C until the ethyl cellulose is completely dissolved in turpentine and alcohol. Mix the low-temperature glass powder and fluorine-doped titanium dioxide according to the mass ratio of 1:3; add an appropriate amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com