Catalytic ozonation and Fenton-like coupling reactor and method for treating toxic refractory wastewater

A wastewater treatment and ozonation technology, which is applied in the directions of oxidized water/sewage treatment, mining wastewater treatment, chemical instruments and methods, etc., can solve the problems of increasing equipment cost, small gas-liquid contact area, disadvantageous wastewater treatment cost, etc., to reduce the cost of wastewater treatment. The cost of wastewater treatment, the effect of increasing the gas-liquid contact area, and improving the efficiency of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

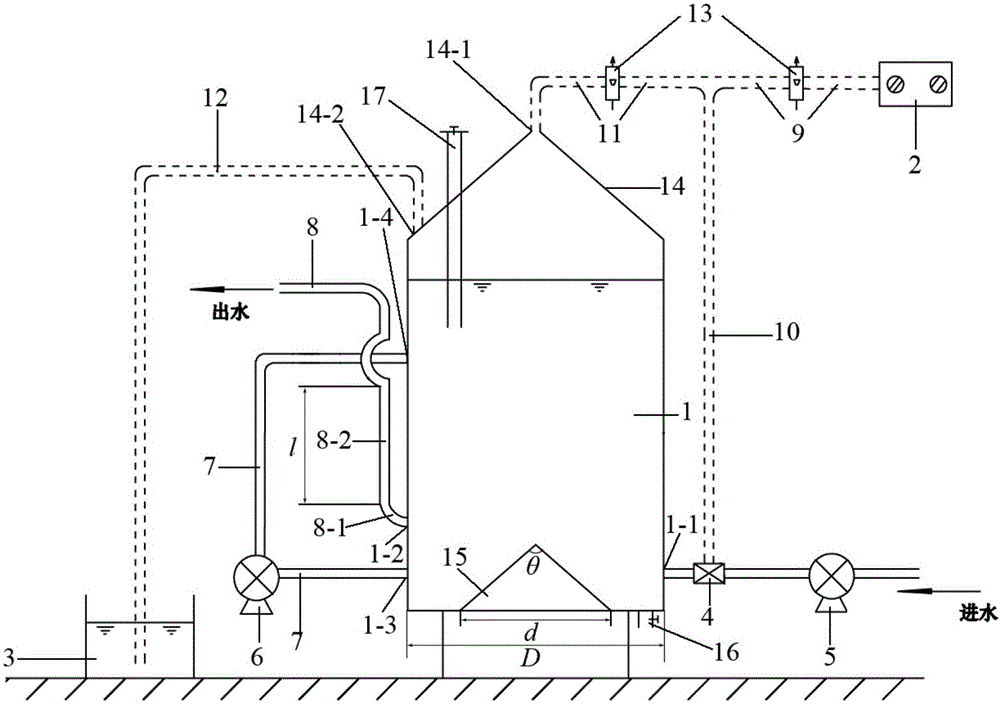

[0033] Embodiment 1: Catalytic ozonation-Fenton-like coupling reactor

[0034] In this embodiment, the structure of the catalytic ozonation-like Fenton coupling reactor is as follows figure 1 As shown, it includes a reaction tank 1, an ozone generator 2, a residual ozone removal device 3, an ejector 4, an inlet pump 5, a return pump 6, a waste water return pipe 7, an outlet pipe 8, an ozone gas supply pipe 9, and an ozone delivery pipe 10 , Ozone return pipe 11, residual ozone discharge pipe 12 and gas flow meter 13.

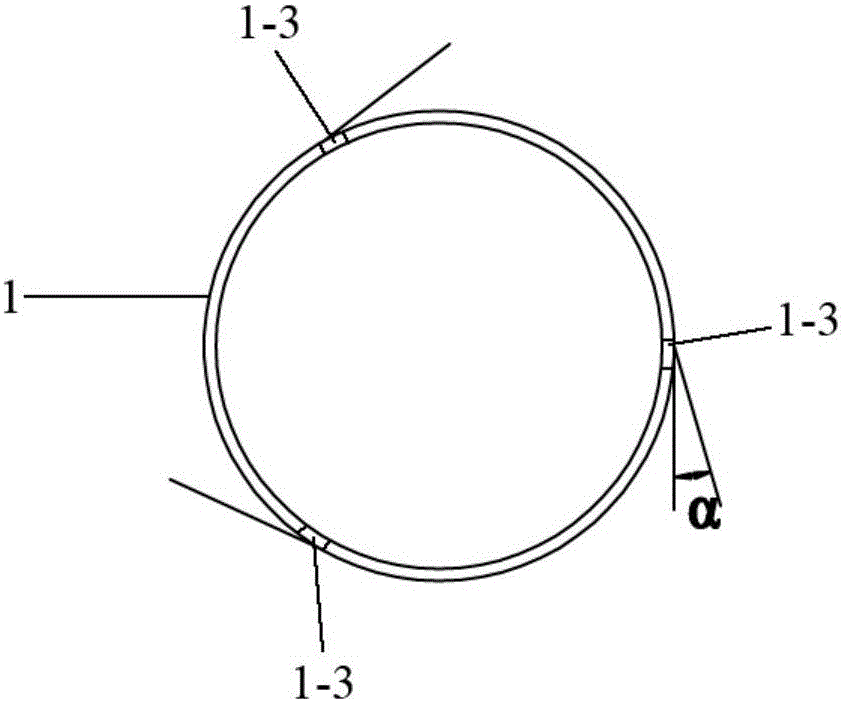

[0035] The reaction tank 1 is composed of a cylindrical body with a closed lower end and an open upper end and a gas collecting hood 14 provided at the opening end of the cylindrical body. The reaction tank 1 is equipped with micron-sized iron-copper bimetallic particles, and the cylindrical body of the reaction tank is closed. The inner surface of the end is provided with a cone 15 with an upward apex, the cone angle θ of the cone is 160°, the ratio of the dia...

Embodiment 2

[0039] Embodiment 2: Catalytic ozonation-Fenton-like coupling reactor

[0040] In this embodiment, the structure of the catalytic ozonation-Fenton-like coupling reactor is basically the same as that of the catalytic oxidation-Fenton-like coupling reactor in Example 1, the difference is that the reaction tank 1 is equipped with micron zero Valence iron particles; the cone angle θ of the cone 15 arranged in the reaction tank is 120 °, and the ratio of the diameter d of the bottom surface of the cone to the diameter D of the reaction tank is 0.7; there are 7 circulating water inlets, and each circulating water inlet is uniform Distributed at the same height position of the cylinder and the angle α between the center line of each circulating water inlet and the tangent of the cylinder at the position is 5°; the length l of the vertical pipe 8-2 of the outlet pipe is 80cm.

Embodiment 3

[0041] Embodiment 3: catalytic ozonation-Fenton-like coupling reactor

[0042] In this embodiment, the structure of the catalytic ozonation-Fenton-like coupling reactor is basically the same as that of the catalytic oxidation-Fenton-like coupling reactor in Example 1, the difference is that the reaction tank 1 is equipped with micron iron Nickel bimetallic particles; the cone angle θ of the cone 15 provided in the reaction tank is 45°, and the ratio of the diameter d of the bottom surface of the cone to the diameter D of the reaction tank is 0.3; there are 5 circulating water inlets, each circulating water inlet Evenly distributed at the same height position of the cylinder and the angle α between the center line of each circulating water inlet and the tangent of the cylinder at the position is 30°; the length l of the vertical pipe 8-2 of the outlet pipe is 50cm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com