Technology for producing nifuratel

A production process, the technology of nifuratel, applied in the field of production process of nifuratel, can solve the problems of dimethyl sulfate toxicity, complex process, high cost, etc., and achieve the advantages of convenient industrial production, good yield and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

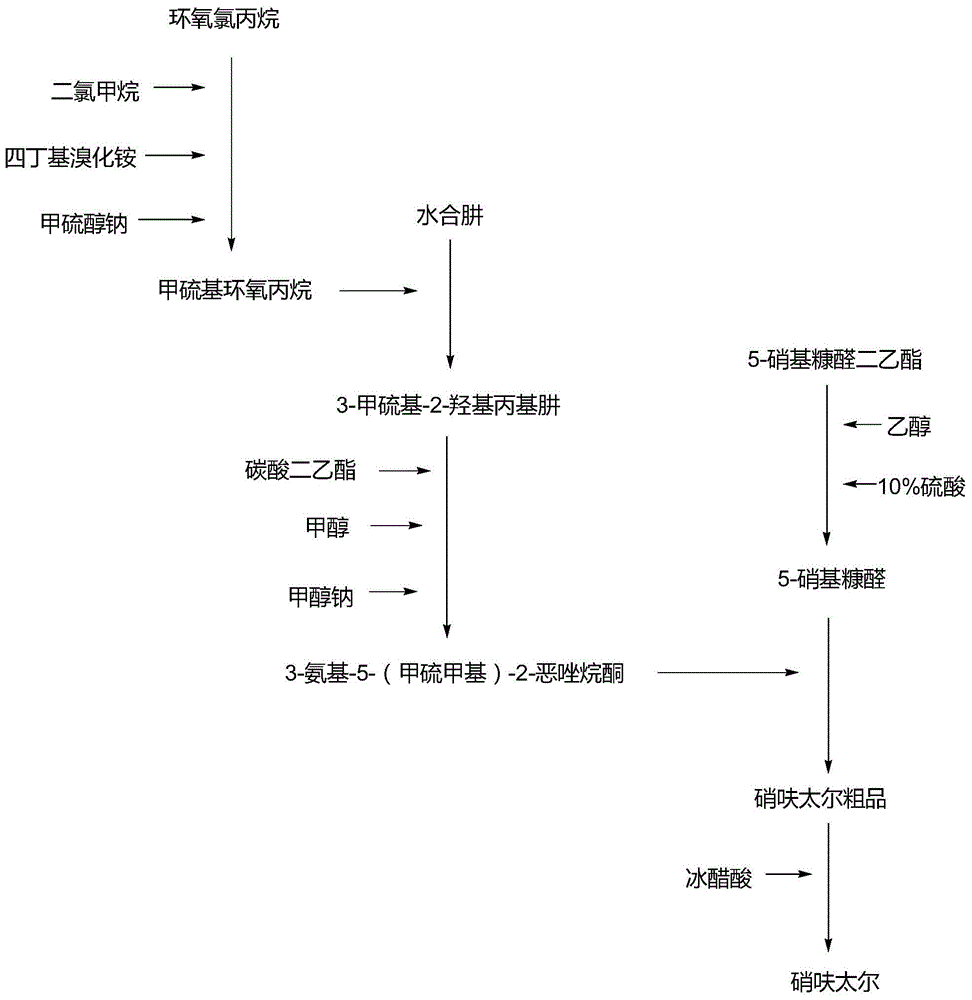

Method used

Image

Examples

Embodiment Construction

[0030] 1. Production raw materials and dosage

[0031]

[0032]

[0033] 2. Production process

[0034] (1) Synthesis of methylthiopropylene oxide

[0035] Into a 50L reactor, add 7.0kg of epichlorohydrin and 0.5kg of tetrabutylammonium bromide into 15L of dichloromethane in sequence, and after adjusting the temperature to 0±5°C, add 24.8kg of mass fraction into the reaction solution dropwise It is 21.5% sodium methyl mercaptide aqueous solution, the dropping time is controlled at 1.5±0.5 hours, and the temperature is raised to 25±2°C for another 1.5 hours;

[0036] Post-treatment method: stand still to separate the liquid, extract twice with 3.5L dichloromethane, combine the organic phases, wash three times with 10L purified water, remove the dichloromethane at a temperature of 40±5°C under normal pressure, and collect by distillation under reduced pressure Distillation at 45-64°C yielded 4.3 kg of a colorless and odorous liquid (methylthiopropylene oxide), with a mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com