High selectivity metal organic skeleton material and preparation method thereof

A metal-organic framework and high-selectivity technology, applied in organic chemistry, separation methods, copper organic compounds, etc., can solve the problems of physical and chemical properties that do not have selective adsorption and separation capabilities, achieve good hydrothermal stability, and shorten processing time , High adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1.02 mg of 2,7-bis(3,5-dibenzoic acid)-9-fluorenone, 8 mg of carbon nanotubes and 1.95 mg of Cu(NO 3 ) 2 2.5H 2 O was dissolved in 3 mL of a mixture of N,N'-dimethylformamide and deionized water with a volume ratio of 8:1, and stirred at room temperature for 30 min. Subsequently, 60 μL of nitric acid solution with a mass concentration of 70 wt % was added to the reaction bottle, and after uniform mixing, the airtight container was moved to an oven for crystallization at 60 °C for 72 h. Open the reaction bottle, filter twice with 10 mL of N,N'-dimethylformamide solution at 50°C, and then filter once with 15 mL of methanol solution; the obtained sample is vacuum-dried for 2 hours, and then filter once with the same volume of methanol solution , followed by drying at 80° C. for 2 h; after drying, the sample was transferred to a vacuum drying oven and dried at 100° C. for 2 h to obtain a metal-organic framework material A.

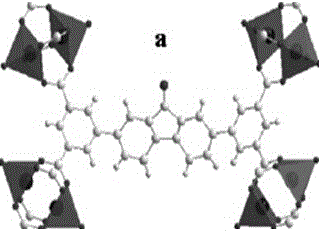

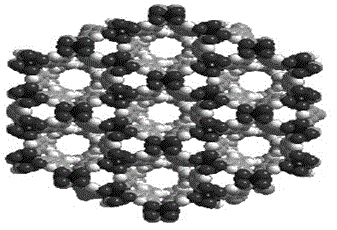

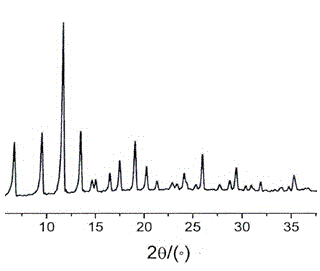

[0038] The determination of the structure of t...

Embodiment 2

[0040] In Example 1, 2,7-bis(3,5-dibenzoic acid)-9-fluorenone was reduced to 0.408 mg, and other reaction conditions and material composition remained unchanged, to obtain pure metal organic framework material B.

Embodiment 3

[0042] In Example 1, the mixed solution of N,N'-dimethylformamide and deionized water with a volume ratio of 8:1 was increased to 6mL, and other reaction conditions and material composition remained unchanged to obtain a pure metal organic framework Material C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com