Composite phase change energy storage material containing ionic liquid and preparation method thereof

A technology of phase-change energy storage materials and ionic liquids, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of not being directly used as phase-change materials, and achieve large-scale popularization and application, low vapor pressure, and overcoming The effect of low thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

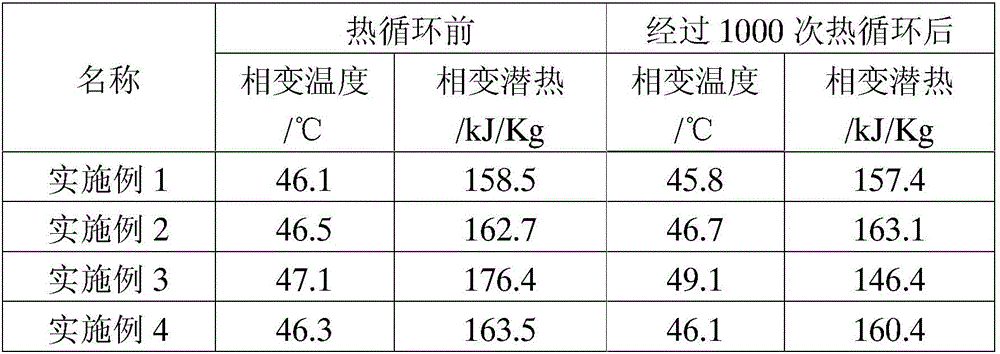

Examples

preparation example Construction

[0031] b. Preparation of propylamine formate ionic liquid: Slowly add formic acid in an equimolar amount to propylamine to an aqueous solution of propylamine under vigorous stirring, react at room temperature for 4 hours, distill water under reduced pressure at 85°C, and dry in vacuum under reduced pressure for 24 hours.

[0032] Store the 1-methylimidazolium dihydrogen phosphate and alanine formate ionic liquid prepared above for future use.

Embodiment 1

[0034] Weigh 22.5g of 1-methylimidazolium dihydrogen phosphate ionic liquid, 22.5g of propylamine formate ionic liquid and 5g of diethanol monoisopropanolamine surfactant in a beaker, and place them in a water bath at 80°C After stirring evenly, add 8.33g of expanded graphite and continue to stir for 1h, then place it in a vacuum drying oven at 60°C for 4h, cool to room temperature after adsorption, and obtain ionic liquid / nonionic surfactant / expanded graphite for air energy water heater Composite shape-setting phase-change materials.

Embodiment 2

[0036] Weigh 47.5g of propylamine formate ionic liquid and 2.5g of fatty alcohol polyoxyethylene ether silane WA surfactant in a beaker, stir evenly in a water bath at 70°C, add 5g of expanded graphite and continue stirring for 2h , and then placed in a vacuum oven at 60°C for immersion for 6 hours, and cooled to room temperature after adsorption to obtain an ionic liquid / nonionic surfactant / expanded graphite composite phase change material for air energy water heaters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com