Method for preparing functional porous micro-spheres

A porous microsphere and functional technology, which is applied in the field of preparation of functional porous microspheres, can solve the problems of lack of active groups and the limitation of direct utilization of natural polymer porous microspheres, and achieves functional regulation and simple preparation process. Ease of operation and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, prepare a kind of functional porous microsphere, the steps are as follows:

[0020] Step 1, prepare NaOH / urea aqueous solution, wherein, NaOH mass fraction is 8%, urea mass fraction is 4%; Add purified chitin powder 300mg to the NaOH / urea aqueous solution of 10g and obtain mixed solution A after dispersing evenly; Mixed solution A was freeze-thawed, that is, the mixed solution A was placed in a low-temperature constant temperature tank, frozen at -20°C for 10 h, and then thawed. After the freeze-thaw process was repeated 3 times, the mixed solution A was frozen in liquid nitrogen to fully dissolve the chitin powder, and the obtained Clear solution B.

[0021] Step 2: Prepare the isooctane / Span80 mixed solution, wherein the volume-mass ratio of isooctane to Span80 is 100:1mL / g; take 20mL of the isooctane / Span80 mixed solution, stir at 500rpm for 30min, and then add to step 1 to prepare solution B to obtain mixed solution C; put mixed solution C in an ice b...

Embodiment 2

[0024] Embodiment 2, prepare a kind of functional porous microsphere, the step is basically the same as the step of embodiment 1, the difference is:

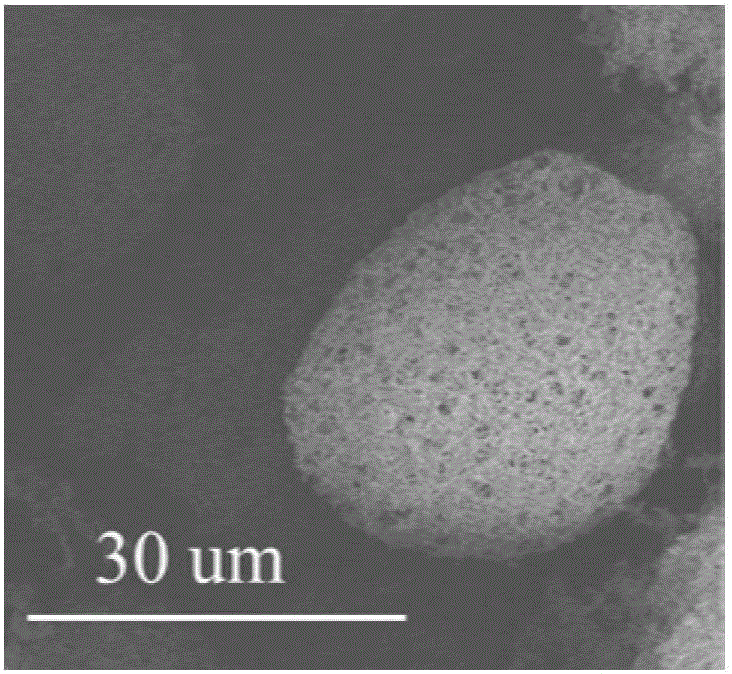

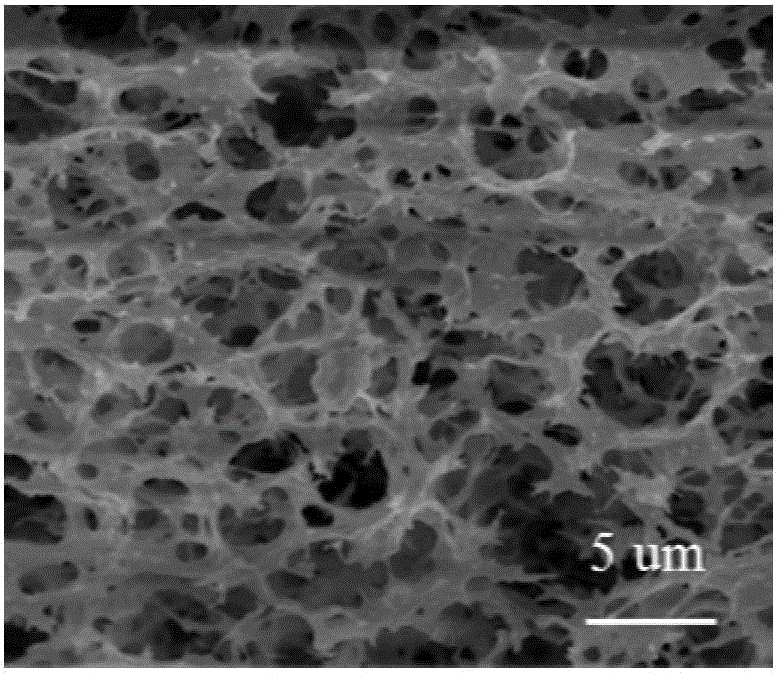

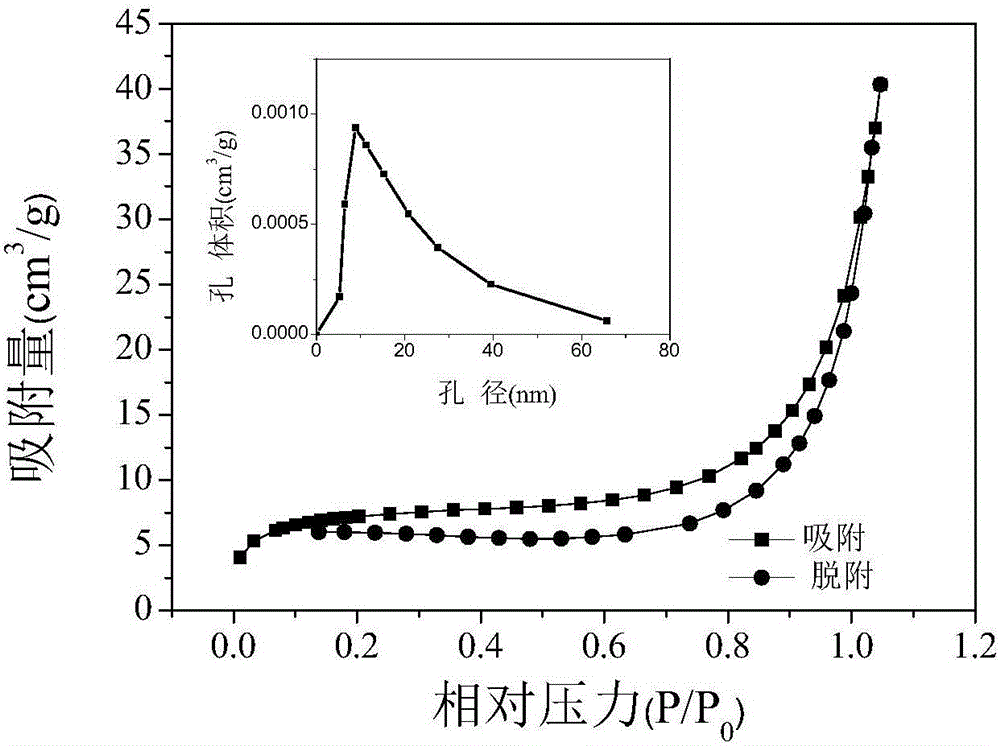

[0025] In step three, disperse 2.5mL of chitin microspheres into 5.3mL of deionized water, then add 0.2mL of tannic acid aqueous solution to the solution, let stand for 1min, then add 2mL of titanium lactate aqueous solution to the solution, and let stand After 1 min, a mixed solution E was obtained. The molar concentration of tannic acid in the mixed solution E was 0.12 mmol / L, and finally functional porous microspheres were obtained. Its specific surface area is 7.62m 2 / g, pore diameter 18.33nm, porosity 0.04cm 3 / g. Figure 3-1 and Figure 3-2 SEM photo of the functional porous microspheres prepared in Example 2.

Embodiment 3

[0026] Embodiment 3, prepare a kind of functional porous microsphere, the step is basically the same as the step of embodiment 1, the difference is:

[0027] In step 3, disperse 2.5mL of chitin microspheres into 3.1mL of deionized water, then add 0.4mL of tannic acid aqueous solution to the solution, let stand for 1min, then add 4mL of titanium lactate aqueous solution to the solution, and let stand After 1 min, a mixed solution E was obtained. The molar concentration of tannic acid in the mixed solution E was 0.24 mmol / L, and finally functional porous microspheres were obtained. Its specific surface area is 9.62m 2 / g, pore diameter 18.36nm, porosity 0.08cm 3 / g. Pic 4-1 and Figure 4-2 SEM photo of the functional porous microspheres prepared in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com