Nano-molybdenum-based sulfur-tolerant methanation catalyst, preparation method and application

A technology based on sulfur-resistant methane and catalyst, which is applied in the field of sulfur-resistant catalyst and its preparation, can solve the problems of inability to apply methanation process, low methane selectivity, poor sulfur resistance, etc., and achieves high stability, high methane selectivity, Good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

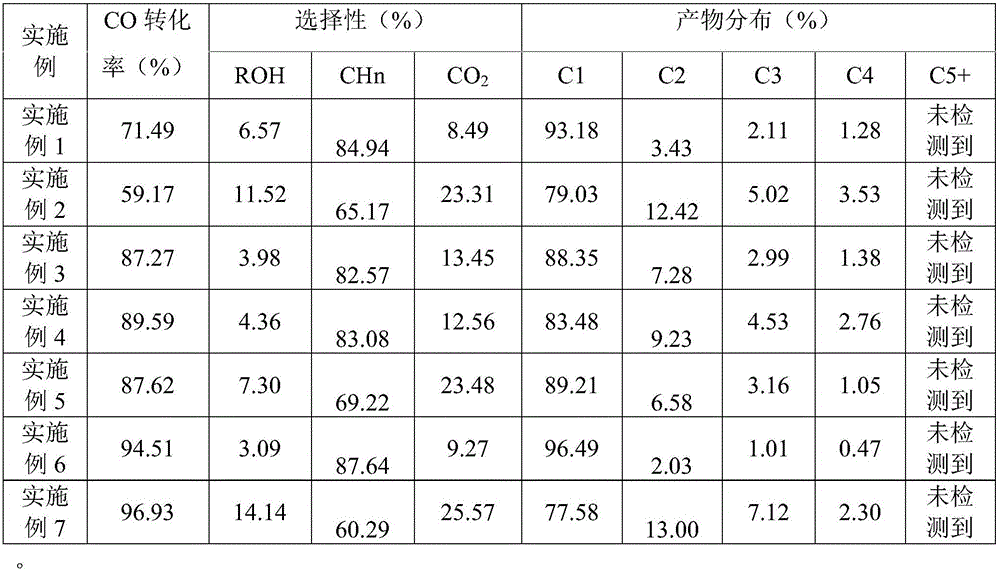

Examples

Embodiment 1

[0054] Weigh 100g of cyclohexane, 50g of cetyltrimethylammonium bromide, and 25g of n-butanol, and stir well to form an oil phase solution; weigh a certain amount of ammonium molybdate and dissolve it in deionized water to form a concentration of 0.01mol / L solution, add a certain amount of citric acid, make the molar ratio of citric acid and molybdenum atom be 10, stir until evenly, get ammonium metavanadate, manganese nitrate (50wt% solution) in addition and be dissolved in with above-mentioned solution, form mixed For solution A, add the mixed solution A dropwise to the above oil phase solution at a rate of 2mL / min, and stir while adding dropwise to form a microemulsion system. Take another sodium carbonate to make a 30wt% solution, add dropwise to the above microemulsion system until the pH value is 8.0, after the reaction is completed, age the mixed solution at 25°C for 24 hours, centrifuge at 5000r / min for 10min, and remove the upper layer After clearing the night, wash ...

Embodiment 2

[0056] Weigh 100g of hexane, 25g of polyethylene glycol octylphenyl ether (TritonX-100) and 25g of n-pentanol, and stir well to form an oil phase solution; weigh a certain amount of ammonium molybdate and dissolve it in deionized water to form a concentration of To a solution of 0.1mol / L, add a certain amount of citric acid so that the molar ratio of citric acid to molybdenum atoms is 5, stir until uniform, and then dissolve ammonium tungstate, ammonium chromate, and ferric nitrate in the above solution to form a mixed For solution A, add the mixed solution A dropwise to the above oil phase solution at a rate of 5mL / min, and stir while adding dropwise to form a microemulsion system. Take another sodium carbonate to make a 30wt% solution, add it dropwise to the above-mentioned microemulsion system until the pH value is 9.0, after the reaction is completed, age the mixed solution at 50°C for 3h, centrifuge at 1000r / min for 30min, remove the supernatant , washed with absolute eth...

Embodiment 3

[0058] Weigh 100g of heptane, 33.3g of dioctadecyldimethylammonium chloride (DODMAC), and 33.3g of n-hexanol, stir well to form an oil phase solution; weigh a certain amount of molybdenum chloride and dissolve it in deionized water to form Add a certain amount of citric acid to a solution with a concentration of 0.5mol / L, so that the molar ratio of citric acid to molybdenum atoms is 5, stir until uniform, and dissolve cobalt nitrate, cerium nitrate, and magnesium nitrate in the above solution to form a mixed solution A. Add the mixed solution A dropwise to the above oil phase solution at a rate of 10mL / min, and stir while adding dropwise to form a microemulsion system. Take another potassium nitrate to make a 30wt% solution, add it dropwise to the above microemulsion system until the pH value is 10.0, after the reaction is completed, age the mixed solution at 80°C for 1h, centrifuge at 3000r / min for 10min, remove the supernatant , washed with absolute ethanol until there is no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com