Xanthate cation dual-modified straw fiber printing and dyeing wastewater treatment agent and preparation method thereof

A technology of straw fiber and xanthate, which is applied in textile industry wastewater treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. The natural polymer flocculant is easy to gelatinize and condense into a frozen state, etc., to achieve excellent water solubility, not easy to gelatinize, and good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

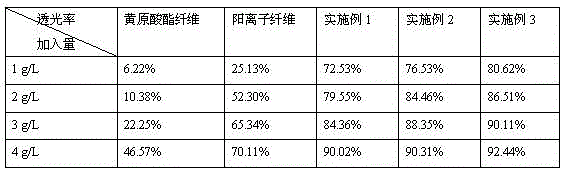

Examples

Embodiment 1

[0027]Xanthate cation double-denatured straw fiber printing and dyeing wastewater treatment agent is obtained by extracting straw fiber from straw and undergoing xanthate cation double-denaturation. The extraction method of the straw fiber is as follows: peel the wheat straw, cut it into small pieces, clean it with distilled water, boil it in boiling water for 1 hour, dry it in an oven, and pulverize it twice with a pulverizer to obtain the straw powder for later use. In the bottle, add nitric acid-ethanol mixed solution with a volume ratio of 1:4 to the reaction bottle to make the solid-liquid ratio reach 1:25g / mL, then install a condensing reflux tube on the reaction bottle, condense and reflux for 1.5h, and heat in a boiling water bath After the powder in the reaction bottle turns white, the residue is washed with nitric acid-ethanol mixed solution, then washed with hot pure water until neutral, and finally washed twice with absolute ethanol, filtered with suction, and dried...

Embodiment 2

[0033] The synthetic method of xanthate cationic double-modified straw fiber comprises the following two steps:

[0034] (1) Weigh a certain amount of straw fiber into a 200mL beaker, add 50wt% NaOH solution, alkalinize for 50min; then press filter and drain to neutral, transfer to a 250mL three-neck flask, add 50mL of 30wt% NaOH dilute solution , while stirring, add 2% CS of straw fiber mass 2 , the reaction temperature was set to 40°C, and 25mL of 1wt% MgSO was added 4 , stirred, and reacted for 2 hours; finally, 0.1wt% MgSO 4 Melt solution, deionized water, 50wt% ethanol, acetone, washing the product to neutrality, drying at room temperature to obtain xanthate straw fiber;

[0035] (2) Weigh the above-mentioned certain amount of xanthate straw fiber into a 250mL three-neck flask, add deionized water, adjust the pH of the system to 11 with 10wt% NaOH solution, heat the reaction system to 40°C, and stir Add a mixed solution of 3-chloro-2-hydroxypropyltrimethylammonium chlo...

Embodiment 3

[0038] The synthetic method of xanthate cationic double-modified straw fiber comprises the following two steps:

[0039] (1) Weigh a certain amount of straw fiber into a 200mL beaker, add 50wt% NaOH solution, alkalinize for 50min; then press filter and drain to neutral, transfer to a 250mL three-neck flask, add 50mL of 35wt% NaOH dilute solution , while stirring, add 2.5% CS of straw fiber mass 2 , the reaction temperature was set to 35°C, and 25mL of 1wt% MgSO was added 4 , stirred, and reacted for 3 hours; finally with 0.1wt% MgSO 4 Melt solution, deionized water, 50wt% ethanol, acetone, washing the product to neutrality, drying at room temperature to obtain xanthate straw fiber;

[0040] (2) Weigh the above-mentioned certain amount of xanthate straw fiber into a 250mL three-necked flask, add deionized water, adjust the pH of the system to 11 with 10wt% NaOH solution, heat the reaction system to 50°C, and stir Add a mixed solution of 3-chloro-2-hydroxypropyltrimethylammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com