High-strength and high-toughness flame retardant and smoke suppressing PVC wood-plastic foaming composite building template and preparation method thereof

A high-strength and high-toughness building formwork technology, which is applied in the field of wood-plastic foamed composite building formwork, can solve the problems of restricting the large-scale use of wood-plastic composite foamed building formwork, poor weather resistance, flammability and smoke generation, etc., and achieve improved flame retardancy Effects of smoke suppression, impact resistance improvement, and lattice integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

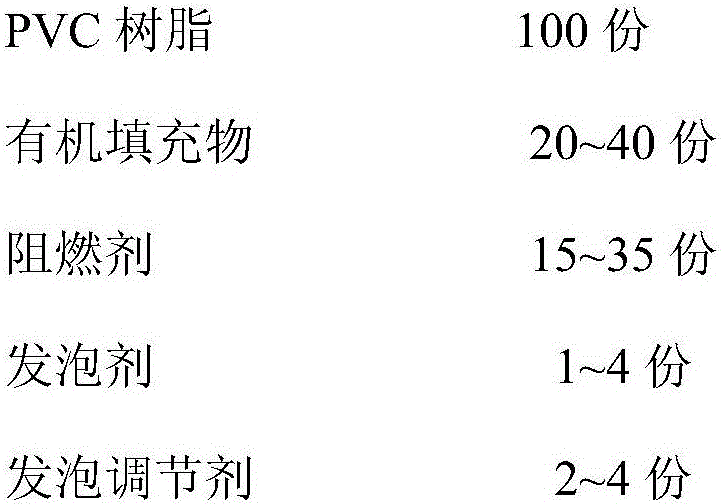

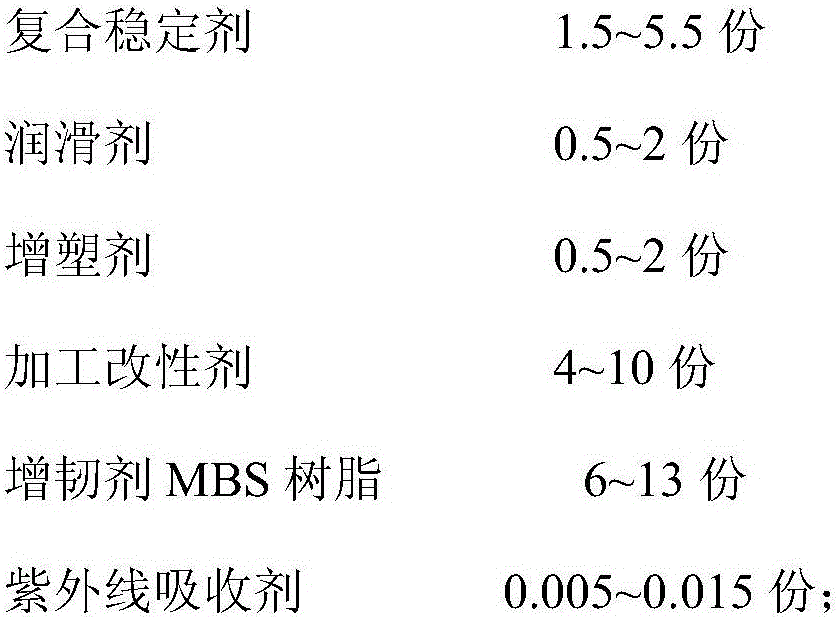

Method used

Image

Examples

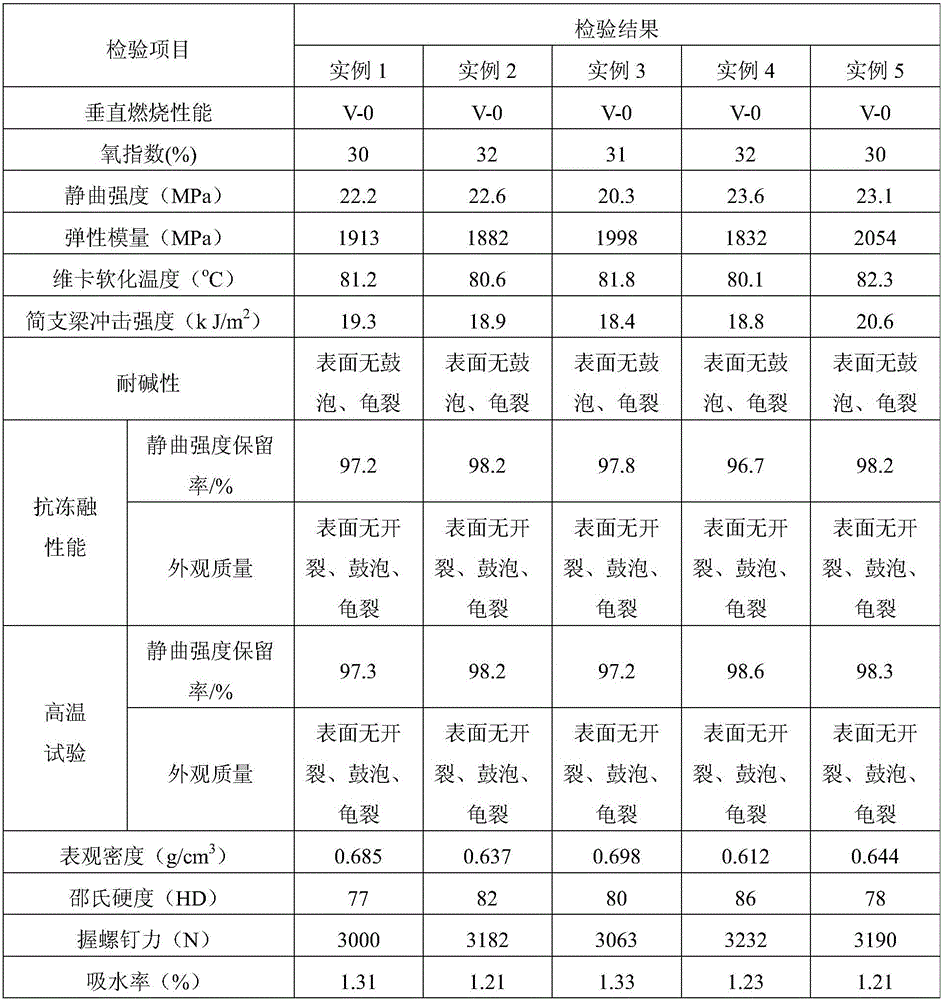

Embodiment 1

[0035] Each component is weighed in parts by weight, respectively weighing 100 parts of SG7 type PVC resin, particle size 200 mesh; 30 parts of poplar wood powder and soybean straw powder mixture, the mass ratio of the two is 1:1; flame retardant alkali 23 parts of magnesium sulfate whiskers; 0.53 parts of coupling agent (γ-propyl methacrylate trimethoxysilane); 3 parts of foaming agent, the foaming agent is AC, NaHCO 3 Mixed blowing agent, NaHCO 3 : AC mass ratio is 2:1; foam regulator ZnO2.5 parts; rare earth composite stabilizer 2.5 parts; lubricant stearin 1.5 parts; plasticizer DOP1 part; ACR processing modifier 8 parts; 8 parts of toughening agent MBS resin; 0.015 parts of a mixture of ultraviolet absorber UV-P and ultraviolet absorber UV-O, and the mass ratio of the two is 1:1.

[0036] Step (1): First dilute the γ-propylmethacrylate trimethoxysilane coupling agent with xylene as a solvent, and couple the plant fiber powder mixture in a jet mixer at a temperature of 65...

Embodiment 2

[0042] Each component is all to be weighed according to weight part, weighs 100 parts of SG8 model resin respectively, particle size 200 meshes; Poplar wood powder 35 parts; Flame retardant basic magnesium sulfate whisker 18 parts; Propyl acrylate trimethoxysilane) 0.53 parts; Foaming agent 3 parts, foaming agent is AC, NaHCO 3 Mixed blowing agent, its NaHCO 3: AC mass ratio is 2:1; foam regulator PbO2.8 parts; barium zinc composite stabilizer 3 parts; lubricant chlorinated paraffin 1.8 parts; plasticizer DOP0.7 parts; processing modifier ACR6 parts; 10 parts of toughening agent MBS resin; 0.01 part of the mixture of ultraviolet absorber UV-P and ultraviolet absorber UV-O, and the ratio is 1:1.

[0043] Step (1): First use xylene as a solvent to dilute the γ-propylmethacrylate trimethoxysilane coupling agent at a temperature of 65-80°C, place the poplar wood powder in a jet mixer, and dilute the The coupling agent is evenly sprayed on the surface of the poplar wood powder to...

Embodiment 3

[0049] Each component is weighed in parts by weight, respectively weighing 100 parts of SG8 type resin, particle size 200 mesh; 30 parts of wood flour and rice husk powder mixture, the mass ratio of the two is 1:1; 23 parts of magnesium whiskers, 0.53 parts of coupling agent (γ-propyl methacrylate trimethoxysilane); 3.5 parts of foaming agent, of which NaHCO 3 : AC mass ratio is 2:1; 3 parts of foam regulator zinc stearate; 2.8 parts of lead salt composite stabilizer; 1.9 parts of lubricant, which is the mixture of zinc stearate and polyethylene wax, zinc stearate: The mass ratio of polyethylene wax is 2:1; 1.3 parts of plasticizer DOP, 9 parts of processing modifier ACR, 11 parts of toughening agent MBS resin, the mixture of ultraviolet absorber UV-P and ultraviolet absorber UV-O is 0.008 and The ratio is 1:1.

[0050] Step (1): First dilute the γ-propylmethacrylate trimethoxysilane coupling agent with xylene as a solvent, and couple the plant fiber powder mixture in a jet m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com