A method for improving the enzymatic hydrolysis yield of alkaline pretreated lignocellulosic raw materials

A lignocellulosic raw material and pretreatment technology, applied in the direction of fermentation, etc., can solve the problems of complicated process and unsuitable for large-scale industrial production, and achieve the effects of simple process conditions, weakened non-specific adsorption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for improving the enzymatic hydrolysis yield of alkaline pretreated wood fiber raw materials, the steps are as follows:

[0027] 1) Weigh 100g of absolutely dry corn stalks and use 10%, 20%, 30%, 40% (g / g, the same below) sodium hydroxide, and the solid-to-liquid ratio 1:10 (g / mL, the same below) ), the amount of polyethylene glycol diglycidyl ether is 10% (g / g, the same below), and the pretreatment is performed at 70°C for 3 hours.

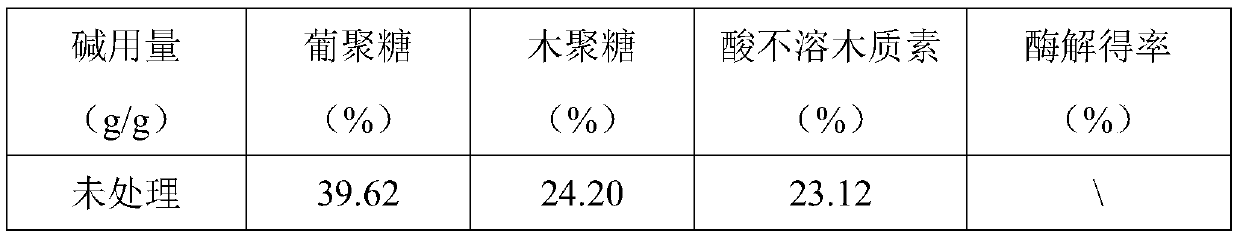

[0028] 2) After the pretreatment, the materials are collected by washing and filtering. Table 1 shows the analysis of the main components of the corn stalks pretreated by polyethoxy ether.

[0029] (3) Weigh the corn stalks pretreated with the above alkali dosage of 10%, 20%, 30%, 40% and polyethylene glycol diglycidyl ether of 10% with the absolute dry weight of cellulose of 1.00g respectively. In two 250mL hydrolysis bottles, add 2.5mL of 1mol / L citric acid buffer, cellulase with enzyme dosage of 20FPU / g cellulose and appropriate amo...

Embodiment 2

[0037] A method for improving the enzymatic hydrolysis yield of alkaline pretreated wood fiber raw materials, the steps are as follows:

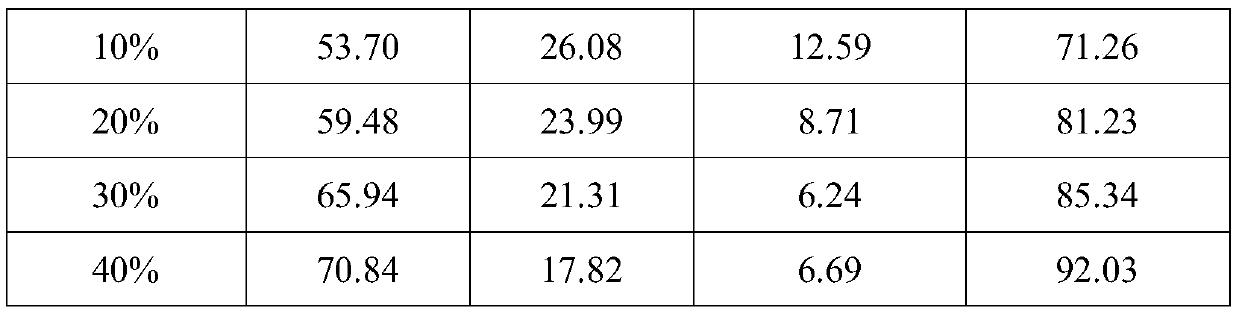

[0038] 1) Weigh 100g of absolutely dry corn stalks, use 10% (g / g) sodium hydroxide, at a solid-to-liquid ratio of 1:10 (g / mL), and the amount of polyethylene glycol diglycidyl ether is 5%, 10%, 20%, 30% (g / g), pretreated at 70°C for 3h.

[0039] 2) After the pretreatment, the materials are collected by washing and filtering. Table 2 shows the analysis of the main components of the corn stalk pretreated by polyethoxy ether.

[0040] (3) Weigh the above-mentioned alkali dosage of 1.00g with the absolute dry weight of cellulose as 10%, and the amount of polyethylene glycol diglycidyl ether as 5%, 10%, 20%, 30% pretreated corn stalks. In two 250mL hydrolysis bottles, add 2.5mL of 1mol / L citric acid buffer, cellulase with enzyme dosage of 20FPU / g cellulose and appropriate amount of distilled water to each hydrolysis bottle to make the total volume of ...

Embodiment 3

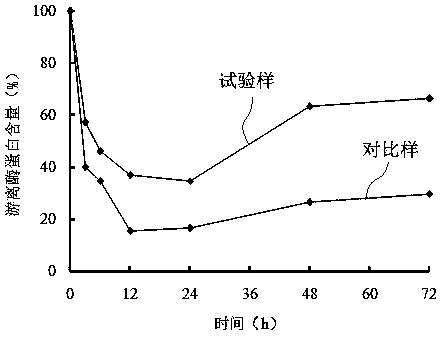

[0046] A method for improving the enzymatic hydrolysis yield of alkaline pretreated lignocellulosic raw materials, cellulase adsorption test, the specific steps are as follows:

[0047] 1) Weigh 100g of absolutely dry corn stalks, use 10% alkali (g / g), solid-liquid ratio 1:10 (g / mL), and 10% polyethylene glycol diglycidyl ether (g / g) Pretreated at 70°C for 3h, filtered and collected the pretreatment liquid and pretreatment materials.

[0048] 2) The pre-treated materials are collected by washing and filtering, and used for cellulose enzymatic hydrolysis.

[0049] 3) Weigh the corn stalks pretreated with 10% alkali and 10% polyethylene glycol diglycidyl ether with the absolute dry weight of cellulose as 1.00g into 2 250mL hydrolysis bottles. Add 2.5mL of 1mol / L citric acid buffer solution, cellulase with enzyme dosage of 20FPU / g cellulose and appropriate amount of distilled water to the hydrolysis bottle to make the total volume of water in the enzymatic hydrolysis system 50mL, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com