Novel method for preparing high quality graphene material

A technology of graphene and a new method, which is applied in the field of preparing high-quality graphene materials, can solve problems such as large environmental hazards, complicated preparation processes, and strong corrosion, and achieve the effects of reducing costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

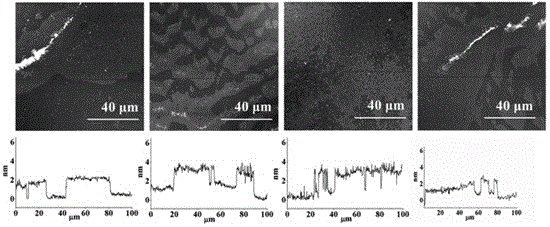

Image

Examples

Embodiment 1

[0025] (1) Water flows through the magnetic field area between multiple NdFeB permanent magnets with a magnetic field strength of 1.1T in a manner perpendicular to the magnetic field direction, so that the surface tension of the water is reduced to 54mN / m and then added to the container.

[0026] (2) Add expanded graphite, natural graphite, polyethylene glycol, quinoline yellow, carmine, sodium citrate and sodium dodecyl diphenyl ether disulfonate into the container of step (1), and use high-speed shear The emulsifier was stirred at a speed of 3500rpm for 3.5 hours to obtain a graphene dispersion. During the process, various raw materials were adjusted or randomly added according to the measured surface tension and viscosity (the raw materials were expanded graphite, natural graphite, polyethylene glycol, quinoline yellow, Carmine, sodium citrate, sodium dodecyl diphenyl ether disulfonate, water), so that the BN parameter of the solution (the value of the BN parameter=the surfa...

Embodiment 2

[0028] (1) Water flows through the magnetic field area between multiple NdFeB permanent magnets with a magnetic field strength of 0.9T in a manner perpendicular to the magnetic field direction, so that the surface tension of the water is reduced to 53mN / m and then added to the container.

[0029] (2) Natural graphite, expanded graphite, polyvinyl alcohol, triethanolamine dodecylbenzenesulfonate, quinoline yellow, sodium dodecyl dinaphthyl ether disulfonate, glycol and dodecyl diphenyl ether Sodium sulfonate is added to the container of step (1), and stirred with a high-speed shear emulsifier at a speed of 3700rpm for 3 hours to obtain a graphene dispersion. During the process, various raw materials (raw materials) are adjusted or randomly added according to the surface tension and viscosity measured. Natural graphite, expanded graphite, polyvinyl alcohol, triethanolamine dodecylbenzenesulfonate, quinoline yellow, sodium dodecyl dinaphthyl ether disulfonate, glycol, dodecyl diph...

Embodiment 3

[0031] (1) Water flows through the magnetic field area between multiple NdFeB permanent magnets with a magnetic field strength of 0.8T in a manner perpendicular to the magnetic field direction, so that the surface tension of the water is reduced to about 55mN / m and then added to the container.

[0032](2) Add natural graphite, expanded graphite, sodium didodecyl diphenyl ether disulfonate, acid red 27, carmine, sodium cetylbenzenesulfonate and propylene glycol into the container of step (1), and use The high-speed shear emulsifier is stirred at a speed of 3800rpm and ultrasonically treated at 100W for 2 hours to obtain a graphene dispersion. During the process, various raw materials are adjusted or randomly added according to the measured surface tension and viscosity (raw materials are natural graphite and expanded graphite. , sodium didodecyl diphenyl ether disulfonate, acid red 27, carmine, sodium cetylbenzenesulfonate, propylene glycol, water), so that the BN parameters of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Conductivity quantity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com