Quaternized chitosan HTCC-silver/polyethersulfone antibacterial membrane and preparation thereof

A technology of quaternized chitosan and antibacterial membrane, applied in the field of membrane separation, can solve the problem of few preparation reports, and achieve the effects of excellent hydrophilic performance, good reproducibility and high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

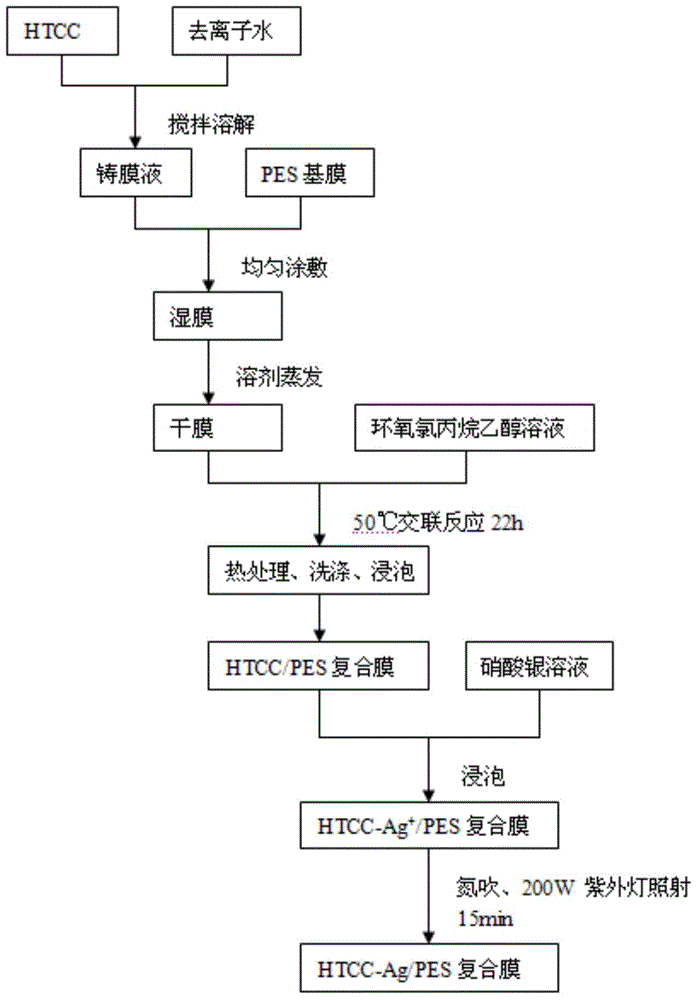

Method used

Image

Examples

Embodiment 1

[0040] Example 1: A certain amount of refined HTCC sample was dissolved in deionized water to prepare a casting solution with a mass concentration of 1.0%, and an appropriate amount of casting solution was absorbed and uniformly coated on the polyethersulfone ultrafiltration membrane to obtain the wet The membrane was placed at 50°C for solvent evaporation for 2 hours. Then, the dry film was immersed in a container containing an ethanol solution of epichlorohydrin with a mass concentration of 1.9%, the ratio of KOH added to epichlorohydrin was 3:6.5 g / mL, sealed, and cross-linking reaction was performed for 22 hours. After the crosslinking reaction was completed, the film was taken out and heat-treated at 50°C for 20 minutes. The composite membrane is washed with deionized water and soaked in deionized water for more than 24 hours. After the membrane is naturally dried, it is immersed in a 0.3mmol / L silver nitrate solution at room temperature, taken out after 30 minutes, and d...

Embodiment 2

[0042] Example 2: A certain amount of refined HTCC sample was dissolved in deionized water to prepare a casting solution with a mass concentration of 1.0%, and an appropriate amount of casting solution was absorbed and uniformly coated on the polyethersulfone ultrafiltration membrane to obtain the wet The membrane was placed at 50°C for solvent evaporation for 2 hours. Then, the dry film was immersed in a container containing an ethanol solution of epichlorohydrin with a mass concentration of 1.9%, the ratio of KOH added to epichlorohydrin was 3:6.5 g / mL, sealed, and cross-linking reaction was performed for 22 hours. After the crosslinking reaction was completed, the film was taken out and heat-treated at 50°C for 20 minutes. The composite membrane is washed with deionized water and soaked in deionized water for more than 24 hours. After the membrane is naturally dried, it is immersed in a 0.5mmol / L silver nitrate solution at room temperature, taken out after 30 minutes, and d...

Embodiment 3

[0044] Example 3: A certain amount of refined HTCC sample was dissolved in deionized water to prepare a casting solution with a mass concentration of 1.0%, and an appropriate amount of casting solution was absorbed and uniformly coated on the polyethersulfone ultrafiltration membrane to obtain the wet The membrane was placed at 50°C for solvent evaporation for 2 hours. Then, the dry film was immersed in a container containing an ethanol solution of epichlorohydrin with a mass concentration of 1.9%, the ratio of KOH added to epichlorohydrin was 3:6.5 g / mL, sealed, and cross-linking reaction was performed for 22 hours. After the crosslinking reaction was completed, the film was taken out and heat-treated at 50°C for 20 minutes. The composite membrane is washed with deionized water and soaked in deionized water for more than 24 hours. After the membrane is naturally dried, it is immersed in a 0.7mmol / L silver nitrate solution at room temperature, taken out after 30 minutes, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com