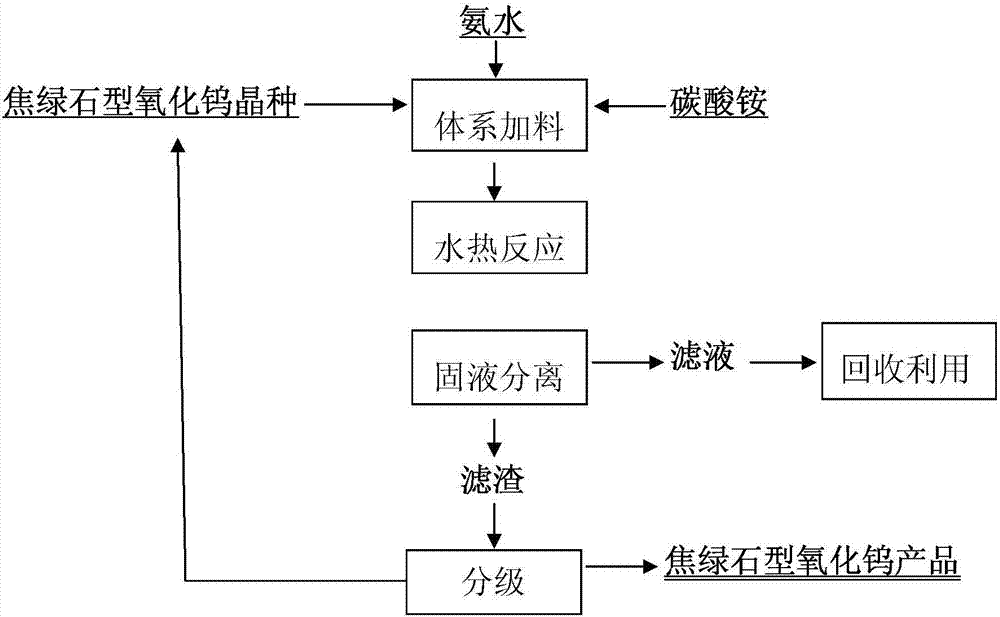

Method for preparing pyrochlore-type tungsten oxide directly from ammonium tungstate solution

A technology of ammonium tungstate and pyrochlore is applied in the field of tungsten smelting to achieve the effect of reducing production cost, wide application range and high tungsten crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

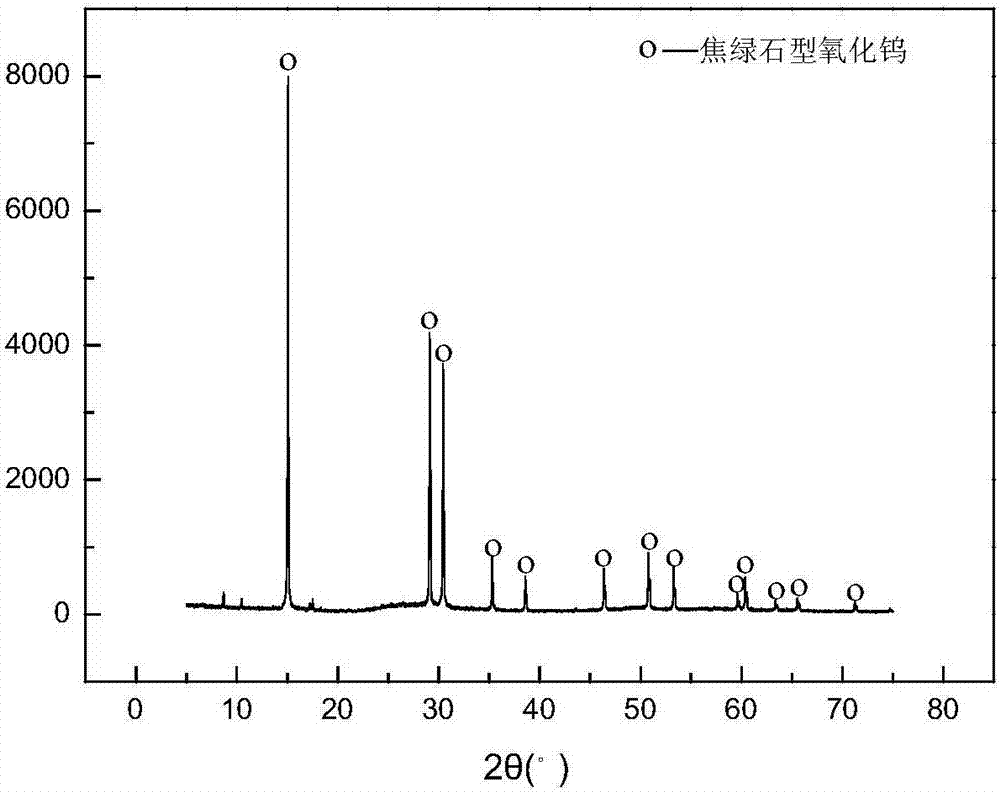

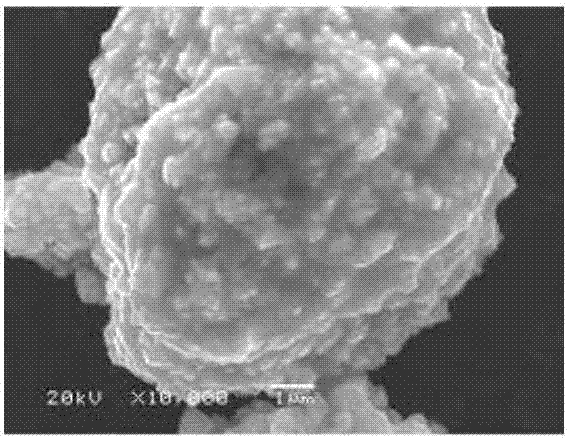

[0058] Embodiment 1: get 50g L -1 Ammonium tungstate solution 50ml, add pyrochlore-type tungsten oxide to the ammonium tungstate solution according to the seed crystal coefficient of 2, and at the same time according to 450g L -1 The concentration of ammonium carbonate is added as solid, and steel balls are added as a stirring medium. Put it into the reaction kettle for hydrothermal reaction, set the temperature of the low-pressure kettle to 120°C, and after 24 hours of reaction, take it out and cool it, then use vacuum filtration, wash the filter cake with pure water three times and then dry it. recycle and re-use. The concentration of tungsten in the filtrate was analyzed, and the decomposition rate of the ammonium tungstate solution was calculated to be 75.7%. X-ray diffraction analysis confirmed that pure pyrochlore-type tungsten oxide was obtained.

Embodiment 2

[0059] Embodiment 2: get 200g L -1 Ammonium tungstate solution 50ml, add pyrochlore-type tungsten oxide to the ammonium tungstate solution according to the seed crystal coefficient of 3, and at the same time, according to 450g L -1 Ammonium carbonate and ammonium sulfate solids are added at a concentration of 100%, and steel balls are added as a stirring medium. Put it into the reaction kettle for hydrothermal reaction, set the temperature of the low-pressure kettle to 130°C, after 24 hours of reaction, take it out and cool it, then use vacuum filtration, wash the filter cake with pure water three times and then dry it, part of it is returned as a seed crystal, and the filtrate is recycle and re-use. The concentration of tungsten in the filtrate was analyzed, and the decomposition rate of the ammonium tungstate solution was calculated to be 76.87%. X-ray diffraction analysis confirmed that pure pyrochlore-type tungsten oxide was obtained.

Embodiment 3

[0060] Embodiment 3: get 300g L -1 Ammonium tungstate solution 50ml, add pyrochlore-type tungsten oxide to the ammonium tungstate solution according to the seed crystal coefficient of 2, and at the same time -1 Add solid ammonium carbonate, ammonia water, and steel balls as the stirring medium. Put it into the reaction kettle for hydrothermal reaction, set the temperature of the low-pressure kettle to 130°C, after 24 hours of reaction, take it out and cool it, then use vacuum filtration, wash the filter cake with pure water three times and then dry it, part of it is returned as a seed crystal, and the filtrate is recycle and re-use. The concentration of tungsten in the filtrate was analyzed, and the decomposition rate of the ammonium tungstate solution was calculated to be 77.86%. X-ray diffraction analysis confirmed that pure pyrochlore-type tungsten oxide was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com