Dianion interface initiator and preparation method thereof

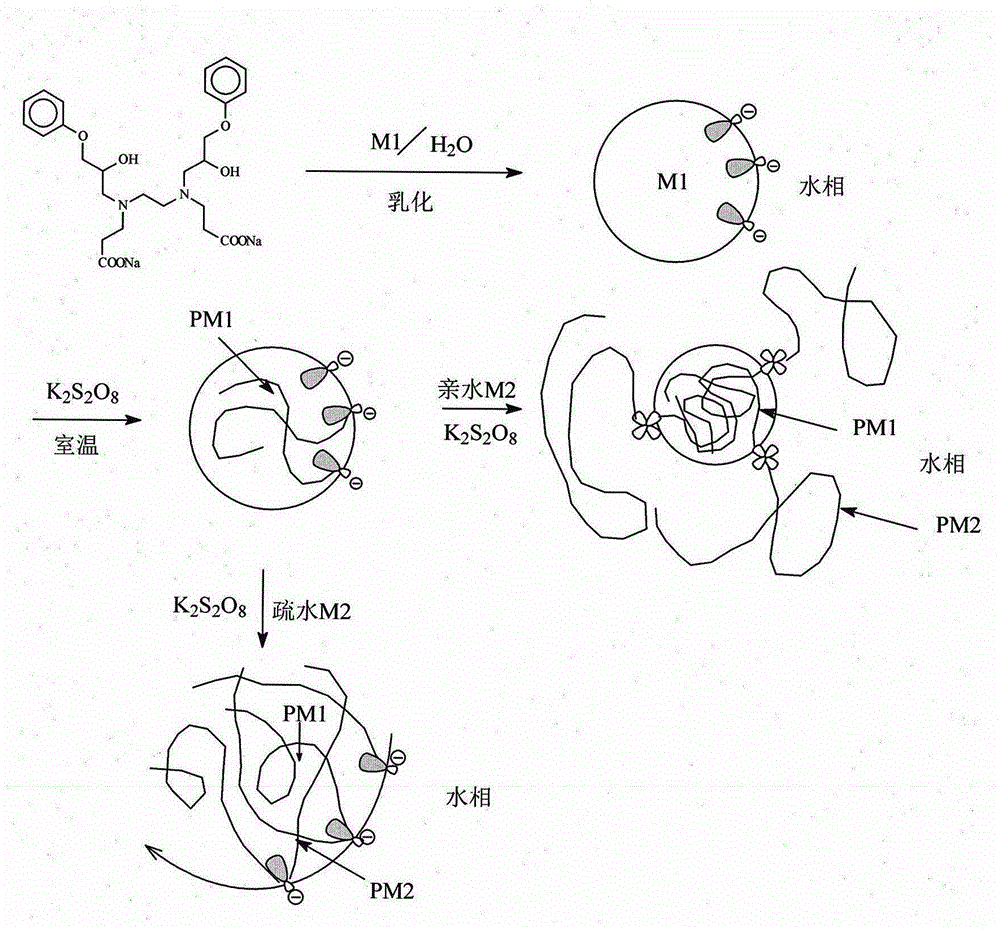

A dianion and initiator technology, used in chemical instruments and methods, cyanide reaction preparation, organic compound preparation, etc., can solve the problem of insufficient functionality of block polymers, inability to achieve cross-phase polymerization, and insufficient initiator improvement. and other problems, to achieve the effect of fast polymerization reaction, high conversion rate, mild and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail.

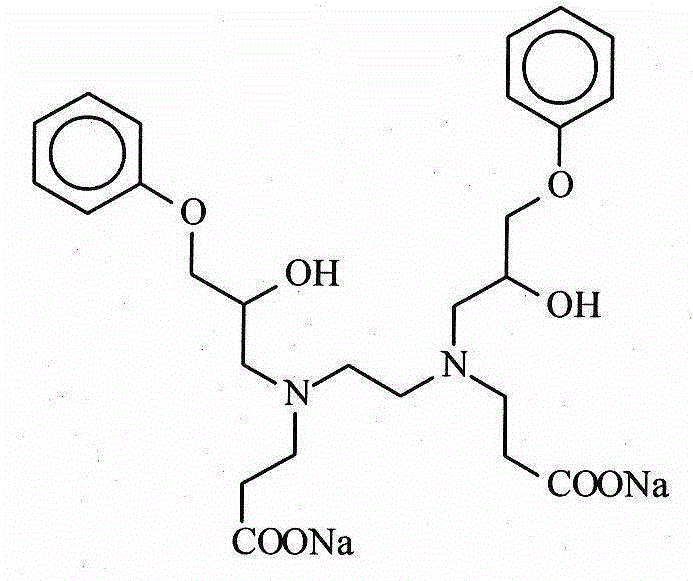

[0020] Preparation of dianion interfacial initiator:

[0021] 1. Dissolve ethylenediamine in absolute ethanol, control the weight ratio of ethylenediamine to ethanol in the range of 1:3~1:3.5, slowly add methyl acrylate and keep stirring, the molar ratio of ethylenediamine to methyl acrylate Keep the ratio of 1:2 as much as possible, control the temperature of the system in the range of 20-25°C, and the reaction time should reach 5-6 hours;

[0022] 2. Add phenyl glycidyl ether to the above reaction mixture, the molar number of phenyl glycidyl ether should be the same as the molar number of the above methyl acrylate, gradually raise the reaction temperature to 40-50°C under stirring, and Reaction at low temperature for 4 to 5 hours;

[0023] 3. Add 30wt.% NaOH aqueous solution to the above reaction solution, the mole number of sodium hydroxide should be 1.2 to 1.5 times the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com