Method for preparing transition metal complex heteroatom-doped porous carbon materials by impregnating recrystallized carbonized biomass

A porous carbon material, impregnation recrystallization technology, applied in the direction of carbon compounds, chemical instruments and methods, non-metallic elements, etc., can solve the problems of harsh reaction conditions, poor transition metal oxides, unfavorable industrial production, etc., and achieve low cost , Improve electrical conductivity, strong energy storage and release capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1, preparation of Co composite N-doped porous carbon material:

[0021] Weigh 4g of Hericium erinaceus, soak in 0.5mol L -1 Co(NO 3 ) 2 In the aqueous solution of 12h, the soaked Hericium erinaceus was freeze-dried in vacuum, placed in a tube furnace, under Ar atmosphere, at 5°C·min -1 The heating rate was increased to 850°C, and the temperature was kept constant for 60 minutes. After cooling, it was washed with distilled water to remove impurities, and centrifugally dried to obtain a heteroatom-doped porous carbon material.

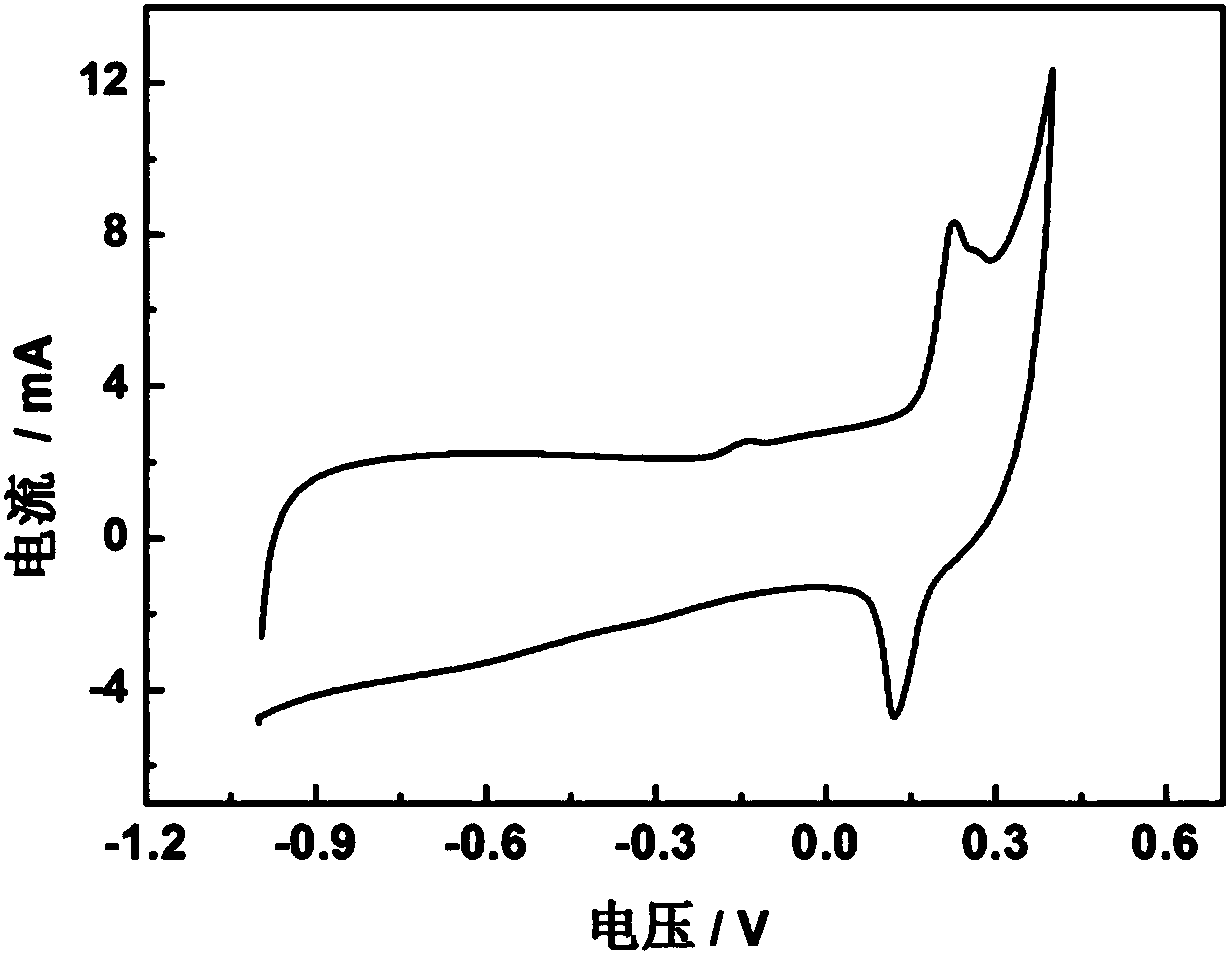

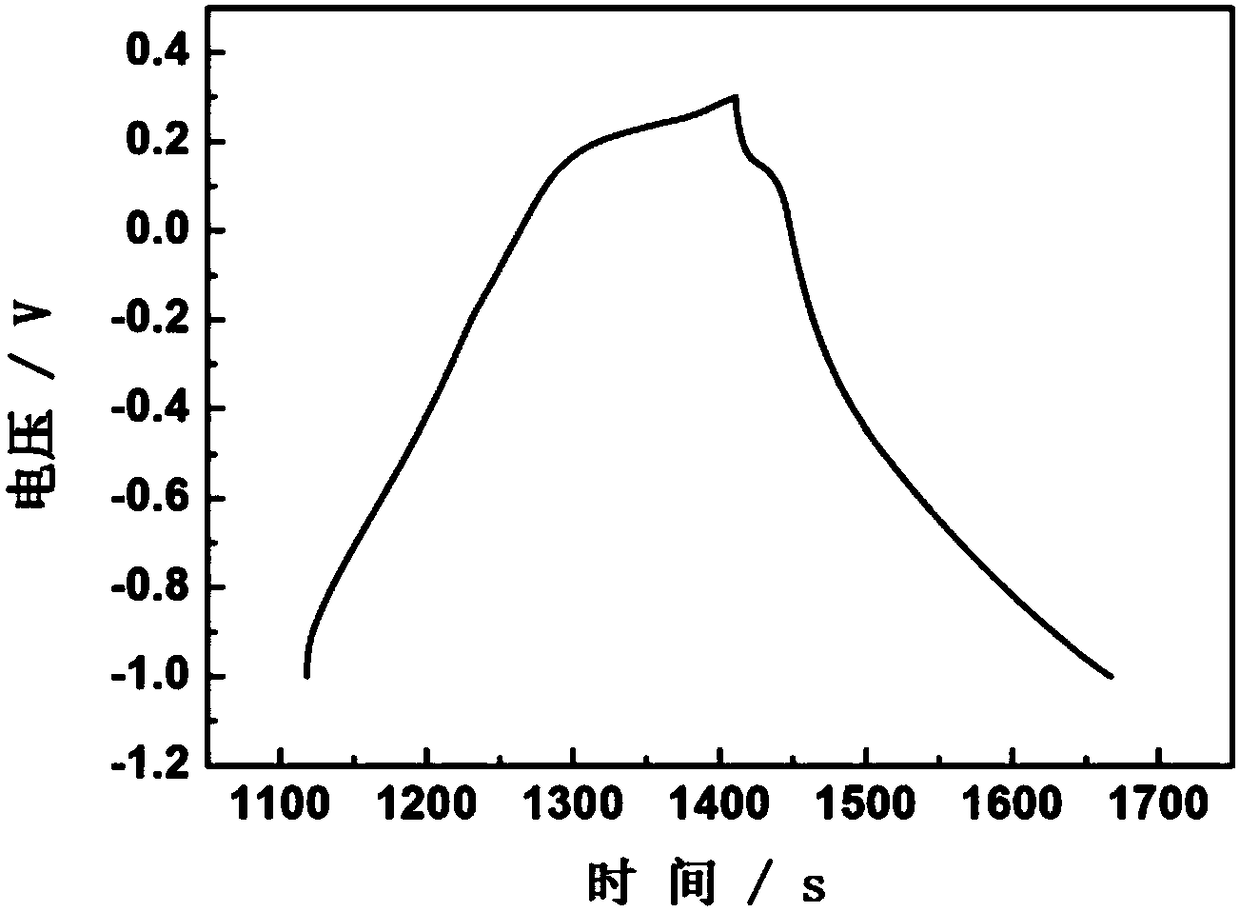

[0022] The physical and chemical properties of the as-prepared heteroatom-doped porous carbon materials were characterized by scanning electron microscopy, figure 1 It was shown that the as-prepared heteroatom-doped porous carbon material had a sheet-like structure on which Co particles were supported. The obtained carbon material image 3 display, which is performed at 1A·g -1 Charge and discharge test under current density, 1A·g -...

Embodiment 2

[0023] Embodiment 2, the preparation of Ni composite N-doped porous carbon material:

[0024] Weigh 4g of Hericium erinaceus, soak in 0.5mol L -1 Ni(NO 3 ) 2 In the aqueous solution of 12h, the soaked Hericium erinaceus was freeze-dried in vacuum, placed in a tube furnace, under Ar atmosphere, at 5°C·min -1 The heating rate was increased to 850°C, and the temperature was kept constant for 60 minutes. After cooling, it was washed with distilled water to remove impurities, and centrifugally dried to obtain a heteroatom-doped porous carbon material.

Embodiment 3

[0025] Example 3, preparation of Co composite S-doped porous carbon material:

[0026] Weigh 4g of Hericium erinaceus, soak in 0.5mol L -1 CoSO 4 In the aqueous solution of 12h, the soaked Hericium erinaceus was freeze-dried in vacuum, placed in a tube furnace, under Ar atmosphere, at 5°C·min -1 The heating rate was increased to 850°C, and the temperature was kept constant for 60 minutes. After cooling, it was washed with distilled water to remove impurities, and centrifugally dried to obtain a heteroatom-doped porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com